Since the end of the 80s, monolithic strip foundations filled with ready-mixed concrete (ready-mixed concrete) have become increasingly popular among the population. began to yield to the practical and convenient monolithic casting of foundations. Not only the strip foundation is cast, but also various combinations of structures: pile-transom, bored piles and others.

Thanks to a wide range of design solutions using monolithic casting, builders are increasingly choosing this technology. This begs the question: What kind of concrete is needed for the foundation?". Our managers answer this question quite often and without much difficulty, however, for a competent answer, you will need information about the construction of the facility and other data.

Concrete grades for the foundation

Concrete grade M100 suitable for the initial stages of construction, pouring footings. The foundation of the concrete grade m100 is suitable for fences, wooden houses, small garages and agricultural buildings.

Concrete grade M150 suitable for light strip foundation, preparatory concrete works. Concrete grade B7.5 is used for the foundations of small one-story residential buildings made of cinder block, foam concrete and aerated concrete. Suitable for foundations of garages, agricultural buildings.

Concrete grade M200 it is used very often in the construction of residential one- and two-story houses with a light type of overlap. This brand of concrete mixes belongs to the structural ones in terms of its strength characteristics and is used in the production reinforced concrete products.

Concrete grade M250 and M300suitable for foundations of large private residential buildings. The M300 brand is used for pouring the foundation of cottages with a height of up to 5 floors. Concrete brand M300 is the first in strength, which is recommended for use for monolithic floors.

Concrete grade M400used in the construction of multi-storey buildings with a height of up to 20 floors.

If your construction site has a ready engineering project and it defines necessary materials for construction, then you don’t need to think too much. The projects usually indicate the required brand of concrete for the foundation and other characteristics. concrete mix. Under the characteristics of concrete is meant its mobility (plasticity), frost resistance and water resistance (water resistance coefficient W).

What brand of concrete is needed for a strip foundation?

Having settled on one of the foundation laying structures, it is necessary to choose brand of concrete for the foundation. Among other questions, the question “where to get concrete?” also arises. The answers are simple. The first option, from the factory; the second is to hire labor and knead by yourself. In 99% of cases it will be correct at the factory.

I wonder why? Read our review "7 benefits of concrete from the manufacturer."

We have already come to the conclusion that concrete should be ordered at the factory. When choosing, it is necessary to take into account the following design parameters.

1) The weight of the structure and the load on the foundation, the number of storeys of the future building, the presence or absence of a basement.

2) Geological survey land plot. Determining the nature of soils, groundwater levels, etc.

3) The type of foundation used and its basement: tape, pile or other.

Each of these points to a different extent affects the choice of brand of concrete for the foundation. Let's consider each of them in more detail.

Foundation Load Prediction- one of the most important parameters when choosing a concrete mix. If we proceed only from the load, then in most cases concrete M200 class B15 is suitable for 1-2 storey buildings. This brand of concrete belongs to structural mixtures and is also used in the production of reinforced concrete products. Often there are cases of using the concrete grade M150 B12.5 for the construction of foundations for private buildings, agricultural buildings and garages. When used as masonry materials of brick (ordinary, silicate, hyperpressed, etc.), gas block, expanded clay concrete blocks, as well as reinforced concrete slabs overlap, we recommend using grades not lower than B20. In the construction of multi-storey buildings using precast concrete or monolithic construction, it is necessary to use a concrete grade for a strip foundation M300 - and higher.

Soil characteristics. In the case of sandy or rocky soils, for a strip foundation and a building of 1-2 floors, you can safely choose low ones - M200. Alas, such soils do not come across so often, and in most cases you have to work with clays, loams and other soils. In such cases, experienced builders strongly recommend using ready concrete for foundation.

Beware the clay! Her main problem is a lot of heaving. As the ambient temperature decreases, clay can expand in volume. Shallow foundation structures are subjected to deformations in winter due to this effect. Relative deformation displacements can reach several tens of millimeters. In addition, such deformations are characterized by unevenness, which is associated with varying degrees of saturation. groundwater.

Thus, a concrete monolithic foundation is affected by different loads along its entire perimeter. That is why, all foundations are laid below the level of freezing (for different latitudes, freezing depths are determined). The freezing depth for the latitudes of Ukraine is about 1 m. In different regions, for one reason or another, experts choose a foundation laying depth of 0.7 - 1.2 m. Leaning on non-freezing soils relieves strip foundations from frost heaving deformations.

foundation types. The strip foundation implies the use of lower grades, but the pile foundation implies the use of higher grades (but not always). Pile foundations are often used in the construction of high-rise buildings, where concrete is poured into piles by special drilling machines. Concrete grades no lower are used there and all requirements for concrete are set by design engineers.

The choice of concrete can also be influenced by the level of groundwater, proximity to water bodies, rivers, and the presence of a basement in the house. Let's discuss the coefficient of water resistance W. Water resistance is the ability of a concrete mix to keep water under pressure from outside. A very important parameter for hydraulic structures. The water resistance coefficient W can vary from W2 to W20, indicating pressure in kgf / sq.cm. For high water resistance of the foundation, you can use external coating waterproofing or purchase a higher brand of concrete in which 100% this coefficient is higher than that of lower ones. For this parameter, we recommend choosing -25.

How much does concrete for a foundation cost?

The cost of concrete for the foundation is determined by its strength characteristics. The bigger and taller your house is, the more durable concrete and a higher grade should be used in pouring the foundation of the future building. High grade concrete uses more cement to create the desired strength. Concrete prices depend on its grade strength (higher grade - more cement).

In this review, we have considered only a part of the parameters and touched the train of thought regarding the choice of concrete for the foundation. In each specific case of choosing the type of foundation, concrete and designing the structure as a whole, it is necessary to approach it individually with the involvement of professional builders.

The foundation is the basis of any building, regardless of its size and purpose. The foundation bears the load from all structures above. The reliability of the foundation depends on many factors, the main of which is the strength of the foundation concrete. In addition to physical characteristics (width and depth), the brand of concrete for the foundation of a private house must correspond to the loads. In the article we will tell you how to correctly determine the brand of concrete for the foundation, what types of foundations exist and what brands of concrete are used for the device. certain types foundations.

There are the following types of foundations;

- Tape

Especially often used in private construction. It is arranged under heavy houses made of concrete and brick. It is a tape of reinforced concrete of the calculated width and depth, arranged under the load-bearing walls of the building, usually with basements.

The depth of laying the strip foundation exceeds the depth of soil freezing. Under light (usually wooden) houses, shallow strip foundations are sometimes arranged.

- Columnar

Support pillars at the corners of the building and at the intersections of the walls.

It is built on stable soils for light buildings. Lintels between pillars can be brick, concrete, rubble. Basements with this type of foundation are not expected. This type of foundation is cheaper than strip foundation, but has limitations in use.

- Monolithic

It is used on highly compressible soils under light (wooden) structures.

In case of moving the ground base monolithic slab prevents the building from collapsing. Construction does without the involvement of technology, the possibilities of planning are not limited. The disadvantage is the impossibility of building a basement and the high cost.

- pile

It is arranged on weak moving soils for structures with high loads. Piles are predominantly reinforced concrete with a bearing load of 2 - 5 tons per unit.

The head parts of the piles are connected to form a support. Convenient in dense urban areas. Reliable and durable, does not depend on the level of groundwater. The method is expensive, not used in private construction.

- slab

Belongs to the group monolithic foundations. The base of such a foundation is the floor of the house.

The foundation is expensive, suitable only for small houses. According to the characteristics corresponds to a monolithic foundation.

- Floating

Such a foundation protects the building from soil deformations.

It is arranged on flooded, on weakly bearing and bulk soils.

- Screw

Included in the group of pile foundations - in this case, a pile is a pipe with a blade.

It is used on flooded construction sites, on heaving soils, unstable soils with complex terrain.

What influences the choice of foundation

The chosen type of foundation depends on the characteristics of the building under construction and the conditions of the construction site. The foundation is chosen according to:

- building load;

- the type and condition of the soil;

- groundwater level;

- depth of maximum soil freezing;

- basement and basement;

- the planned life of the building;

- type of materials used for construction.

Dependence of the grade of foundation concrete on the object

The criteria by which the type of foundation is determined are set out above. If exists finished project object, then it indicates the selected type, its characteristics and the brand of concrete for the construction of the foundation. Each type of building and structure under construction corresponds to the brand of concrete used in the construction of the foundation.

M100 is used for footing in preparatory stages construction. The foundation of concrete of this brand can be built for wooden houses, garages, fences, farm buildings.

M150 is used for preparatory work, for pouring foundations of shallow tape type, small one-story houses, houses made of aerated concrete, foam concrete and cinder block. Can be used for foundations for garages and agricultural buildings.

· M200 is used in the construction of private houses up to two floors with light ceilings. Concrete of this brand belongs to structural and goes to the production of reinforced concrete products.

· M250 and M300 are used for the construction of foundations for large individual houses. Concrete M300 goes for monolithic floors.

· M400 is used for the construction of foundations in multi-storey construction and floors.

Characteristics of concrete

Some of the most important characteristics that affect the choice of concrete for the foundation.

- Mark and class of concrete (M and B)

A characteristic that reflects the ability of concrete to withstand compressive loads. M (concrete brand) - the average value of the maximum pressure per 1 sq. cm, which the concrete sample can withstand 28 days after mixing. B (concrete class) - more modern version strength characteristics with a variation of 13%. The higher the M and B values, the stronger the concrete.

It is handicraft impossible to check what brand the concrete has. With a special sclerometer device, you can determine the quality of the mixture right when pouring concrete into the formwork, but this requires specialists.

- Concrete mobility (P)

Characteristics of the flow or workability of concrete. Index P from 1 to 5 determines the ability to settle the mortar cone by a certain amount. The higher the value of concrete mobility, the more liquid concrete was used for pouring. In the foundations under individual houses concrete with mobility P-2 or P-3 is used. For ease of laying, you can not add more water to the mixer - this inevitably reduces the strength of concrete and can be dangerous for the foundation of the house.

- Water resistance of concrete (W)

The index (W) is indicated by numbers from 2 to 20 and is called the water resistance coefficient. It is possible to increase the water resistance of the prepared concrete by using special hydrophobic additives in the production of concrete mix for the foundation.

- Frost resistance (F)

It is denoted by the index F and has values of 25 - 1000. It characterizes the ability of concrete saturated with water to keep cycles of "freeze - thaw" while maintaining strength characteristics. Coefficients F100 - F200 are typical for individual construction. The value depends on the conditions of construction (climate, humidity, type of soil), as well as the quality of work on waterproofing the foundation.

Requirements for concrete mix components

The composition of concrete includes four components: cement, crushed stone, sand, water. The main thing is that concrete must exactly match its strength brand. Briefly, the requirements for each material:

Active component of concrete. For foundation concrete, cement M400 or M500 is used (not to be confused with the brand of concrete!).

The selected cement should have a minimum shelf life (for a month of storage at a temperature of 20 ° C indoors, M400 cement loses its properties by a quarter, and half when stored outdoors).

- rubble

A filler that provides strength to concrete. For a reinforced structure, which is the foundation, according to the norms, a crushed stone fraction of up to 40 mm is needed. To select the desired fraction, you need to take into account the minimum distance between the reinforcing bars. The selected crushed stone of the maximum fraction should not exceed this distance by more than ¾.

It is preferable to use crushed granite or crushed gravel 5 - 20 mm for pouring the reinforcing cage and 20 - 40 mm for pouring over the ground. Limestone crushed stone can only be used to prepare concrete for foundations on dry soils.

- Sand

Quarry sand is suitable - it must be washed and sifted with the minimum amount clay impurities.

River sand is finer and usually contains a lot of clay, which is undesirable for concrete production. If there is no choice, then river sand should be carefully sifted and washed.

- Water.

Pure water without biological inclusions, oil products, oils. Usually tap water is used.

The ratios of the components of the concrete mixture of various grades are given in the table:

Making concrete at home can be viewed on the video.

Choosing concrete for the foundation

The choice of brand of concrete is dictated by operational characteristics and economic feasibility. A strong foundation, if not needed, will lead to unjustified construction costs, so it is important to correctly determine which brand of concrete is needed. As a rule, private housing projects in Russia offer strip foundations (more than 70% of the total number are being built). To determine the brand of concrete for a strip foundation, you need to take into account everything that affects the foundation.

- M200 and M250 - a brand of concrete for a strip foundation for small brick houses up to 2 floors. This is partly explained by the complex hydrogeological conditions of construction. On solid rocky or sandy soils, you can limit yourself to the M150 brand of concrete, but such soils are rare. Clay soils and loams are characterized by high heaving. At negative temperatures in winter, such soils increase in volume, and unevenly due to different levels of groundwater. In this case, the foundations are often deformed, so the laying depth must be made below the freezing level of the soil.

- In flooded soils and near water bodies, it is important to ensure the watertightness of the foundation. The need for reliable insulation is also needed in the construction of basements. Prevention of pressurized water filtration through the concrete of the foundation is achieved by the device of external coating waterproofing or the use of concrete of a higher grade. In such circumstances, it is required to compare costs and choose a less expensive option.

- It is also promising to use waterproofing additives in concrete. Such additives, when interacting with water, form complex water-insoluble salts of the crystalline structure. These crystals fill microcracks and pores in concrete. Concrete becomes more dense and does not let water through even at high pressure. Such compounds are added to the mixer with concrete at the construction site or when preparing the mixture.

- M150 - wooden houses light weight, lady made of aerated concrete, foam blocks, warm ceramics, country houses, outbuildings, garages, shallow foundations;

- M200 and M250 - brick 1-storey houses with monolithic and reinforced concrete floors;

- M300 and M350 are brick cottages of 2-3 floors with thick walls, reinforced concrete floors, designed for long-term high loads.

To determine the brand of concrete for the construction of the foundation, you need to use the recommendations outlined, then take into account additional construction conditions and, depending on them, make a final decision on the brand of concrete.

What kind of concrete is needed for the foundation of the house updated: November 25, 2016 by: Artyom

Regardless of which of the buildings is planned to be built (a skyscraper made of glass and metal, a dacha, cottage, fence, garage), its basis will be the foundation. The responsibility that falls on construction specialists in the process of foundation production is quite high. When calculating and choosing a concrete grade for the foundation of a house or other building, one should take into account a large number of parameters on which the durability, stability, and safety of the structure under construction depend.

One of the components of the foundation is concrete. The result of all works on the construction of the facility will depend on how correctly the solution is selected and eventually used.

Back to index

Parameters that can help you choose the right concrete for the foundation

To determine which brand of concrete is needed for the foundation, it is necessary to take into account several parameters, including:

The expected load is the most important indicator when choosing.

When calculating the load, it is clear that the structure of reinforced concrete will be much larger in mass compared, for example, with a prefabricated panel object. This can lead to the fact that in the 1st case it is necessary to take a mixture of concrete with increased strength and viscosity characteristics. For buildings that are heavy, we can recommend a brand from M350 and above. Mark up to M350 should be used for light buildings.

The next parameter is soil properties. Soil features significantly affect. Resistance to possible deformations (which can be caused by displacement, for example, sandy, loamy or other similar types of soil) can be achieved by selecting a special one for the foundation. If the soil is sandstone or rocky, the M200 or M250 grade may be sufficient. If there are clay deposits on the ground, then the M350 may be a more suitable brand.

One of the problems with clay is heaving. If the foundation is being built shallow, during the freezing process in the winter period, there will be an uneven rise of the soil, which depends on the speed and degree of saturation with water.

Before you start building a house, you need to choose the type of foundation, and determine what kind of concrete will be required to fill it.

There is 1 tip for this. In such cases, it will be necessary not only to choose the right brand of concrete, but also to dig much deeper than the freezing line in order to avoid possible problems further.

The next parameter is groundwater. The proximity of groundwater will affect the search for. Water resistance is a criterion that should be guided primarily by the proximity of groundwater.

You should pay attention to the fact that you will definitely need to remember about seasonal changes in the available area. They can lead not only to the rise of waters, but also to their release to the surface. This may lead to negative impacts to the foundation.

Back to index

In order for the structure to maintain its integrity in the event of a possible danger associated with groundwater, the following recommendations should be followed:

- After choosing concrete, if there are doubts, it makes sense to perform external waterproofing. It can be done using roll materials or coating materials, which include bituminous mastic, hydroglass isols, and so on.

- An ambiguous outcome option concerns soaking with special ones.

- Initially, you can choose a mixture of high-grade concrete, but in this case there are some nuances. Such concrete is quite expensive, and it is necessary not only to be able to work with it, but also to have time to use it. The thing is that setting will occur much faster than with ordinary grades, and this will lead to the loss of the concrete itself and the money that was spent on it.

- There are special additives that can increase the density and water resistance of concrete.

Back to index

What elements should be taken into account when choosing a brand of concrete?

Cement. When determining what composition and brand of concrete is needed for the selected type of foundation, you should know that there are a fairly large number of varieties of cement, including: without additives and with additives, Portland cement, normalized, fast-hardening, waterproof, plasticized frost-resistant, resistant to aggressive environments and etc.

For the foundation, the M300 brand is most suitable, but the builders recognized the M500 brand as optimal.

Fittings. Speaking about which reinforcement is most suitable for the foundation, it is worth knowing that experts advise choosing a cell design with perpendicularly connected rods. Reinforcing bars for foundations are characterized by a corrugated surface, which gives the concrete the ability to completely envelop the element that is embedded in the foundation.

It is important to note that the reinforcement must be completely included in the thickness of the base, while not reaching the bottom.

Solution. When choosing a brand of mortar for foundations, you need to know that, in addition to cement, clay and lime can be added to the mortar, and therefore the choice is expanding. Solutions can be cement with a different ratio of incoming components, cement-lime, cement-clay, which are used for foundations on dry ground. In the case of an increase in soil moisture, it will be necessary to increase the amount of cement that is included in the composition.

Back to index

The choice of concrete depending on the type of foundation

The grade of cement for a tape-type foundation for manual laying can be as follows:

- M100: 220 kg of cement, 0.8 cubic meters of crushed stone, 0.6 cubic meters of sand, 180 liters of water.

- M200: 280 kg of cement, 0.8 cubic meters of crushed stone, 0.5 cubic meters of sand, 180 liters of water.

- M250: 330 kg of cement, 0.5 cubic meters of crushed stone, 0.6 cubic meters of sand, 180 liters of water.

- M300: 380 kg of cement, 0.8 cubic meters of crushed stone, 0.45 cubic meters of sand, 180 liters of water.

The durability and stability of any type of foundation depends on many factors. The most important are the quality and brand of concrete. The success of all construction cycles directly depends on how it corresponds to the type of construction of the house, the quality of the soil and the type of foundation chosen.

In the presence of project documentation, the main criteria have already been identified by professional architects. Therefore, the task of builders is to clearly follow the developed project, in which the brand of concrete has already been determined. However, what to do if independent arrangement of the foundation is supposed?

Brief information for individual developers

Before deciding whether to purchase a concrete mix or independently produce it on a site, you need to understand what basic properties should be taken into account.

Any concrete consists of three main components, the quality of the concrete mixture itself depends on their percentage in cement.

Water plays the role of a solvent for the fillers present. Fillers such as crushed stone, gravel, sand and other bulk additives reduce the stress of the hardening foundation and can significantly reduce the cost of the foundation being built. Cement is a link between the two components listed above.

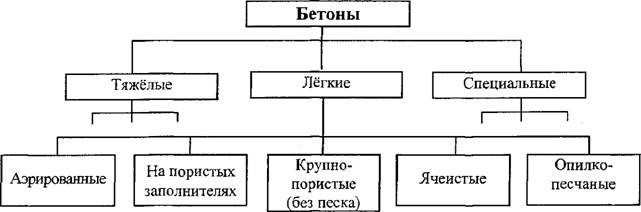

Classification by purpose and use of concrete

Concrete mixture, as a material for construction, is usually divided according to the following main characteristics: according to its purpose and application, type of binder, average density, strength characteristics, water resistance and frost resistance.

This can be a variety of conditions, such as resistance to emerging loads (including vibration and shock), fire resistance and resistance to sulfates. Here are the following types of concrete:

- ordinary - for the installation of beams, foundations, columns and ceilings;

- types of mixtures used for sidewalk and road surfaces, etc.;

- hydraulic mixture - for the production of works on the lining of water structures;

- special purpose concrete: heat-resistant or acid-resistant types and others.

Production different types concrete depends on under what conditions and for what reinforced concrete structures it will be used.

By type of connecting component

The binder component that is part of the solution determines its fundamental characteristics. Main types:

- gypsum - made on the basis of gypsum. This building material is used for the device suspended ceilings and interior partitions. This category also includes gypsum-cement pozzolanic mixtures, which are characterized by a high rate of water resistance. They are used in the construction of various structures of low-rise private houses, including bathrooms;

- cement concretes / mortars - are produced on the basis of cement. Most often, their main binder component is Portland cement / its types. The scope of use of mixtures based on Portland slag cement and pozzolanic cement is the construction of residential buildings.

This category also includes decorative mixtures of different colors. The most expensive of them is white. This group includes concrete mixtures based on alumina, non-shrinking and tensioning cement;

- slag-alkaline - a relatively new type of concrete. It is used in the construction of large structures;

- polymer-cement - contains latex additives, cement and soluble resins. This type has been successfully used in landscape design, For decorative finishes walls (inside and outside);

- heat-resistant and acid-resistant - include liquid glass, alkaline glass and other binders;

- silicate - using lime. Rarely used in private construction. It is mainly used for arranging panels, ceilings and large blocks.

The first indicator means the ability of the mixture not to pass water coming under pressure. According to it, the concrete grade is classified from W2/4/6/8/12. Recently, the letter F has been replaced by B.

The index of resistance to frost in GOST is designated by the letter F and indicates the number of maximum possible freezing and thawing with a decrease in weight and strength by a certain amount. The better the density of concrete, the higher its frost resistance. The lowest grade of concrete in this case is F25, and the highest is F1000.

Choosing the right brand of concrete

After determining the type of future foundation, it is necessary to decide which brand is suitable in order to arrange the foundation of a private house. When determining the proportions of the components, it is necessary to take into account:

- structure weight;

- the expected load on the base;

- soil features on the site for the construction of a house, the level of water occurrence, freezing, and others;

- the presence of a basement.

Based on the general information given at the beginning of the article, it follows that the higher the load, the higher the concrete grade should be. For example, a concrete mortar M200 or M250 is suitable for a lightweight wooden or prefabricated panel cottage, and the construction of a strip foundation for a brick house will require the use of M300.

Accounting for the natural features of the site

When determining the composition of the mixture, one should take into account the structure of the soil and the characteristics of the climatic zone in which construction is underway. The brand of concrete is selected depending on the level of water rise and seasonal freezing.

The required parameters, namely, water resistance, mobility, rigidity, frost resistance depend on Portland cement. In accordance with established and justified requirements, its grade should be 2 times higher than the finished concrete solution.

So, for concrete with an indicator of 300, the M600 brand is suitable. However, this ratio can be reduced to 1.5 or 1.0 for rocky or sandy soils. But, in the presence of clay or swampy soils, the quality of concrete will have to be increased by 50 units or more.

Independent production of cement mortar for the foundation

For self-manufacturing concrete, attention should be paid to the purity of the additional components:

- fillers such as crushed stone, gravel or sand should not have various inclusions;

- the binder must have a proper shelf life and the required moisture content.

In order for the solution to obtain the required strength, you should select the required brand and strictly adhere to the ratio of water. The general proportion of the concrete mortar is as follows - 1: 3: 5 (3 parts of sand and 5 crushed stone must be added to one part of cement).

Preparation of concrete M 200

To mix the mortar, you will need Portland cement M 400 per 1 m³ in the following proportions:

- 320 - 380 kg of Portland cement M400;

- 930 kg of sand;

- 1550 kg of crushed stone;

- 155 kg of water.

Experts say that even if all proportions are observed, there is no guarantee that as a result the builder will receive a mixture of the M200 brand. The properties of the concrete mixture to a large extent depend on the moisture content of the components, the quality of the mixing of the mortar and the order in which it is laid into the structure.

Ready-mix concrete, as well as components for its independent production on the site, should be purchased only from trusted manufacturers.

The brand of concrete for the construction of the foundation of the house must exceed the declared characteristics from 30 to 40%. Following this principle will ensure the reliability of the foundation and the entire structure during operation.

What concrete is better to buy for the foundation of a private house?

The construction of an industrial complex or a multi-storey building necessarily begins with pouring a reliable foundation. The further fate of the upcoming architectural project will directly depend on the quality of the foundation, as well as on the technology of its pouring. Well, the reliability of the foundation is provided by the material for pouring from which it is made. We are talking about high quality concrete. Next, we will consider which one is better to buy or do it yourself, so that the foundation of the building is considered as reliable as possible in accordance with GOST.

Grade of concrete for the foundation

The first thing to note is the brand. If we are talking on the construction of bridge structures, hydraulic structures and industrial buildings, it is recommended to take ready-made, grade M400, that is, high density, which includes all kinds of plasticizers, as well as crushed granite. What concrete for the foundation is useful in civil engineering? For the strip foundation of the house, you can also use a lower density of the commodity, characteristic of the top class M200 and M350 brands. M200 is a universal brand of cheap with increased consumption, which is recommended for use in the construction of the foundation of residential houses. The filler of the concrete mixture in this case is gravel, lime or crushed granite.

The next thing we pay attention to is the predicted load on a residential or industrial building. Every builder should keep this in mind. What kind of concrete is needed for a tape-type foundation used in the construction of prefabricated panel houses? As a rule, this is the M200 brand. For foundation high-rise building from stone it is better to use a more reliable option - the M350 brand. This brand is recommended for the arrangement of floor slabs and bearing walls. As for concrete for stairs, floors with a small load and wooden buildings, here you can opt for the M250 brand, the strength of which is slightly less than that of the M300 and M400 brands. The cost with the delivery of such concrete in a concrete mixer-type machine will be the most optimal for housing construction.

Soil properties

Many people give advertisements in newspapers like “I will buy concrete”, without even thinking about the fact that you need to pay no less attention to the properties of the soil than to the previous parameters. Rocky soil is a continuous mass of quartzite, granite, sandstone. It is resistant to moisture, as a result of which the W-2 grade can be used in the construction of buildings on rocky and sandy soils. As for clay soil, it is very susceptible to compression. The moisture content of the clay soil will determine the bearing capacity. What brand is suitable in this case? To build a building on such soil, it is better to resort to grades W-8 and W-12.

Grade of cement

Before thinking about where to buy concrete with delivery, take into account the fact that the brand of cement used in the preparation will largely determine its quality. The higher the brand of cement, the higher will be the quality of the concrete mixture and its price. If it is necessary to obtain concrete at the output, which is characterized by resistance to prolonged frosts, then cement grade PC 500-DO is recommended, plus anti-frost additives. The final one will be durable and waterproof. Cement PC-500 DO can be actively used for repair and restoration work. The calculation of the amount of cement can be carried out both manually and using a special online calculator.

Porosity of concrete

Porosity, which also determines its quality, can be open and closed. In the first case, we are talking about capillary pores, microcracks and open cracks. In the second case - about the pores of the gel. Large open porosity can adversely affect technical specifications building material, including resistance to chemicals, moisture, low temperatures. Concrete with closed porosity properties is much more preferable.

The composition of concrete for the foundation with impurities

Impurities or additives per cube can have a significant impact on the characteristics of the concrete composition and its quality. On sale there are both individual impurities and concrete with impurities already added, for which you do not need to think about how to make and calculate the correct composition. The dynamic properties of dry and liquid concrete can be improved through the use of superplasticizers, which make it more dense, refractory and strong, plus exclude moisture penetration. If the building is being built at a temperature of -15 ... -25 degrees, then the composition and proportions must contain frost-resistant components. To protect the concrete solution from corrosion, special proportions are used for the foundation with modifiers that reduce the resistance of the building material to low temperatures and moisture.

Certification

Certification is commonplace in manufacturing throughout the world, but in Russian Federation it is not required. And yet, thinking about how to choose concrete, we strongly recommend that you pay attention only to certified products with documents in the appropriate form, or at least to those manufacturers who have a good reputation in the region.