When planning a foundation for a house, the option is mainly chosen when it is used monolithic slab on a strip foundation.

This base is most preferable compared to other types of foundations due to its good stability on unstable soils. This type of basis evenly transfers the load from the walls of the building and presses its entire area onto the ground.

Collection of information and preparation

To avoid irreparable mistakes, the execution of work must be deliberate, and the approach to the process should be serious and balanced. The house begins with the foundation and to make it reliable it is necessary to understand the details.

Any construction begins with large-scale preparatory work. Especially when we are talking about the foundation for the future building. There are no trifles here and you should start with a survey of the site, that is, the qualitative characteristics of the soil.

This type of basis is good because it is used in areas where groundwater is close to the surface, peat soils and “float”. But, nevertheless, a geodetic study is necessary, since it will make it possible to plan not only the foundation for the house as a whole, but also help in calculations with determining the technical parameters of the foundation, arranging waterproofing or abandoning it, etc.

Applied information

Here is one option for peat soils. Step-by-step instruction stages:

- A meter layer of peat is removed and thus a foundation pit is prepared.

- The bottom is leveled with a permissible difference of 3-5 cm.

- Sand is laid on the bottom, moistened and compacted.

- Geotextiles are laid on the prepared "pillow".

- The next layer consists of crushed stone, which is also compacted with a rammer.

- A formwork structure is installed, which is mandatory for monolithic foundations.

- Reinforcement is welded and installed to create a waterproofing barrier.

- The reinforcement skeleton is set in two levels: lower for tension, upper for screed.

- The concrete mixture is poured, compacted with a vibratory tool by removing air bubbles from the concrete.

- The surface is smoothed and left to dry.

- The slab is ready and after 2-3 weeks the formwork is removed.

- If the construction of walls is postponed to spring, the foundation is covered with roofing material in winter, the formwork remains.

The following description is designed for soils of different friability and freezing, you can call it a general plan of action.

After the pit is dug, it is necessary to continue work on cleaning the bottom of the pit. This can be done both manually (using a shovel) with an allowable error of five cm, and with the involvement of special equipment (mini excavator), which is equipped with a bucket without teeth (planning bucket), using a laser level, the bottom of the future base is leveled under a monolithic slab.

Next, on the “smoothed” bottom, it is necessary to pour concrete preparation. For this, low-grade concrete is used, the layer of which is about 10 cm. This will help reduce the error along the base horizon.

The laying technology is as follows. A two-layer waterproofing is filled on the bituminous primer. One layer of waterproofing goes along, the other - across the plane of the monolith.

Mandatory is the formwork, without which pour monolithic foundation impossible. The most suitable material for this is laminated plywood.

A monolithic slab on a strip foundation has the peculiarity that the strips in such a base are provided for those places where a large load is not expected, that is, we are talking about extensions of various terraces, stairs, verandas, porches.

Used with such a device, the base is classical reinforcement. What does it mean? It is a process of reinforcement with two meshes. The bottom one is for tension, the top one is for compression.

After the waterproofing is ready and the formwork is installed, the lower mesh is knitted. The lower layer of reinforcement is installed on special stands. At the final stage, concrete is poured, which must be “tamped down with the help of vibration”, this procedure will remove air bubbles from the concrete mixture and make the monolith better and stronger.

Yes, in in general terms looks like a monolithic slab device.

Application area

Quite often, being reinsured for the construction of a house, it is a monolithic slab on a strip foundation that is chosen. This basis is universal in terms of stability, both on solid soils and on those that are close to the surface of groundwater or the peat composition of the soil. The following aspects can be listed that lead to the choice of this particular basis:

- the planned house will have significant weight due to the materials used or the high number of storeys,

- loose or "floating" soils,

- uneven soil for compressibility,

- high level of melt water and the proximity of underground to the surface of the future construction site.

The construction of just such a foundation is due to a number of positive points:

- a monolithic slab on a strip foundation is able to compensate for vertical and horizontal displacements of the soil,

- the structure is very simple in design and universal for all buildings on any soil,

- the possibility of constructing a basement floor that is not exposed to water.

Initial stages

Now in more detail about the monolithic structure. It is most often preferred because it is definitely more durable than prefabricated options. For information, all existing skyscrapers are built precisely on a monolithic foundation, so such a foundation for your own home is just right. The foundation can be shallow and deep - it all depends on the structure of the soil at the construction site.

The depth of the pit can reach 1.2-1.5 meters, it also depends, in addition to the soil, on how many floors there are in the planned building. But, nevertheless, alumina is selected and a “cushion” is arranged. It is done by laying a layer of sand, which is moistened and compacted, then a layer of crushed stone is laid, which is also compacted. This bedding, with a thickness of 20 to 30 cm, will avoid dripping water to the base of the building.

A PVC film or roofing material is laid on the prepared layer before arranging the structure of the monolithic slab. This is necessary so that the concrete solution does not dehydrate when pouring the foundation itself.

On a flat pit, the corners of the future structure are marked and in advance (if this is planned) sewer and rainwater pipelines.

- Formwork is made from durable boards at the bottom of the pit. This frame is made by hand using boards and laminated plywood sheets or simply from boards (more than 2.5 cm thick) and cuts throughout the frame structure.

During installation, it is necessary to leave a small space between the slope of the excavation and the base plate.

Leveling is also performed using a level and checked for strength before pouring the concrete solution.

The structure must be strong, since the pressure on the walls when pouring the concrete mixture will be large. The fastening on the sides must be particularly secure. It is better to check the strength of the structure at the end. To do this, it is enough to make a few kicks with the foot. The reliable design will remain in the exposed position, but if there are any shifts, inclinations, the frame must be redone.

Basic procedure

- Prior to the start of concrete pouring, a waterproofing layer is laid on the prepared “cushion”. This can be both modern construction developments, and ordinary, inexpensive film or roofing material.

- The device of a monolithic slab is a process of laying two levels of a reinforcing cage on prepared layers. Moreover, they are installed perpendicular to each other - one along, the other across. This is due to the fact that the lower one works in tension, the upper one works in screed. The first level is 5 cm from the bedding, the second is 5 cm from the upper surface of the future slab of a monolithic strip foundation. On average, a slab is obtained with a thickness of 20-40 cm. Although this largely depends on what kind of building will be built, from what materials, plus the “behavior” of the soil.

The reinforcement for the frame is taken with a section of 16 mm (a relative value, since the reinforcement is selected based on the weight of the future structure and the condition of the soil), it is knitted into cells (20x20cm) with an ordinary steel wire.

If the plan provides for the presence of pipelines or other main lines in the foundation slab itself, then holes (taking into account the diameter of future pipes) for such lines are made in advance. At the end of the laying, the gaps between the walls of the foundation and communications are sealed.

- On the final stage concrete mixture is poured into the prepared reinforcement plane. It is not necessary to save on the foundation of the future structure; it is better to use a solution of a high class in terms of its strength. The mixture must be resistant to frost, low and high temperatures, have a high degree of moisture impermeability. For better performance of the procedure, it is better to use a concrete pumping unit, and completely fill the entire solution once.

- Concrete after pouring is compacted with an electric vibrating tool (to remove air bubbles). It is smoothed out along the level and left in the formwork until it is completely hardened into a single monolithic slab.

It should be said that the choice of this base design is very good for self-construction, since it excludes any oversights and blunders.

Today in low-rise housing construction are used various technologies, allowing the use of foundations different types both powerful and lighter. But the most commonly used monolithic slab or strip foundation.

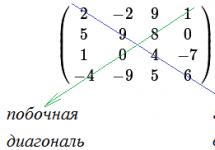

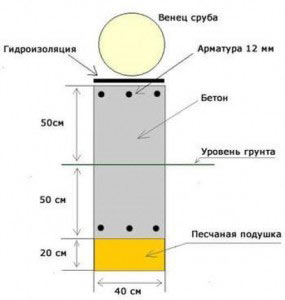

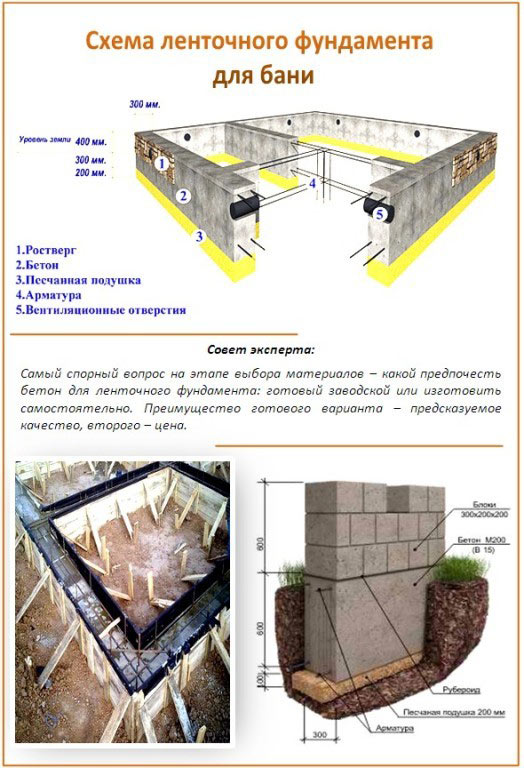

Scheme of samples of strip foundations.

The article talks about the features, advantages and disadvantages of these types of foundations to help you make the right choice.

Table for calculating the strip foundation for the house.

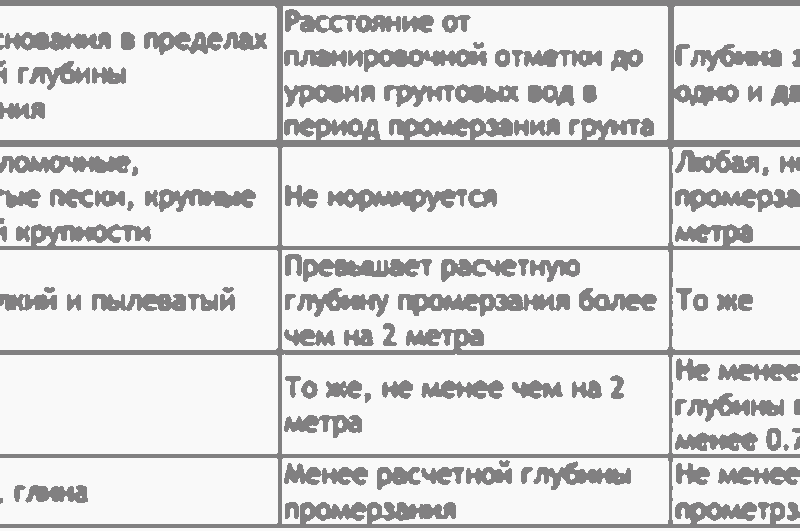

As you know, in our climate, the top layer of soil freezes in winter. The water contained in it expands when it freezes, and the soil, as a result, swells. When freezing to a depth of 1.5 meters, swelling of the soil can be 10-15 cm.

The foundation is needed, first of all, so that these processes do not warp or destroy the house. In addition, it helps to evenly distribute the load on the base of the house, in other words, on the ground. Its design is determined by the weight of the structure, the type of soil, the depth of freezing, and the level of groundwater. Three fundamentally different types have been developed:

- Buried - resting with its base on a fixed non-freezing ground.

- Shallow (floating) - a solid and durable slab under the house, moving along with thawing and freezing soil. Due to its strength, it does not allow the house to collapse or warp.

- Insulated monolithic slab, which excludes freezing of the soil under the house, for which it is carefully insulated around the perimeter.

Structurally, foundations are divided into the following types:

- columnar - the cheapest;

- pile;

- tape type (prefabricated and monolithic);

- slab.

As already noted, the foundations of the last two types are most often used for low-rise construction. The choice of a particular type depends on the design of the building, the magnitude of the loads transferred to the base, and the bearing capacity of the soil.

Tape base

Scheme of reinforcement of the strip foundation.

For most of the European part of Russia, it is traditional. Tape can be block (prefabricated) or monolithic. If a cellar is planned to be built under the house, then the foundation must be monolithic, otherwise the seams between the blocks will reduce the tightness of the structure and you will have to significantly spend money on reliable waterproofing.

There is nothing particularly complicated in the technologies for the construction of strip foundations. But to get a strong and durable design, you need to work hard and spend money. The depth of its laying should be at least 20 cm below the freezing level of the soil (in the North-West of Russia - 1.5 m). Only under this condition, the base rests on non-freezing soil, not subject to swelling.

The material from which the foundation is constructed and the thickness of its tape are uniquely related to each other:

- reinforced concrete - minimum thickness 10 cm;

- concrete - 25 cm;

- rubble concrete - 35 cm;

- masonry - 50 cm.

Scheme of a tape monolithic foundation.

Unlike other types, the technology for manufacturing tape is distinguished by its functional simplicity, but it requires large expenditures of building materials, primarily concrete. Formwork is required, sometimes a crane. The construction of such foundations is a rather costly and time-consuming task.

They are usually used in the construction of heavy houses: stone, brick, with weighted reinforced concrete or metal floors. They also have to be used where there is a threat of uneven precipitation. The strip foundation works in this case as a single monolith, redistributing the load over the entire area, protecting the building from deformation.

Prefabricated belt

Scheme for calculating the loads on the foundation.

The blocks are from 30 to 60 cm thick. The first row of blocks is mounted on a concrete base 10 cm thick. The next rows of blocks are laid on a cement mortar overlapping so that the seams in rows adjacent in height do not coincide with each other.

To build a foundation of rubble concrete around the perimeter of the future house, a trench with a width slightly larger than the width of the wall is first dug. Then the trench is filled with large stones with the addition of small stones to the voids between them. Finally, all this is poured with liquid concrete.

If the construction of the basement floor is planned, the foundation must reach the level of the floor on the first floor. If there is no basement or cellar, it should rise 15-20 cm above the ground.

On an inclined section, blocks are laid in ledges from a lower level to a higher one. In this case, the length of the ledge should be twice its height.

Monolithic tape

Foundation construction scheme.

For pouring, first, approximately the same trench is dug as for the foundation of rubble concrete. The bottom of the trench is covered with a pillow of coarse gravel or crushed stone 30 cm thick and carefully compacted. If the soil is dense and does not crumble, then the walls of the trench can act as a formwork, and the removable formwork will only need to be installed above the ground level.

To prevent the formwork from deforming under the pressure of poured concrete, additional stakes are driven into the soil that support the formwork walls. From above, its edges are connected by planks so that they do not diverge. Large gaps in the formwork, through which concrete can flow out, should be covered with pieces of some kind of film.

In loose sandy soil, the formwork will have to be installed to the bottom of the trench. Reinforcement is installed in the finished formwork and fastened with soft wire, and then concrete is poured into the formwork. Hardening concrete is covered with straw mats or burlap and watered for 2-3 weeks so that the concrete sets and does not dry out. Ultimately it turns out reinforced concrete structure, durable and monolithic.

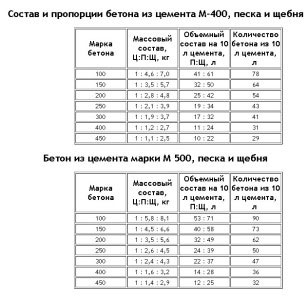

The recipe for the preparation of concrete for a monolithic foundation depends on the properties of the soil in which it is being built. In ordinary soils, the ratio of crushed stone, sand and cement in a solution is 5:3:1. For wet soils, a ratio of 4:2:1 is recommended.

Shallow-depth tape

Such a foundation is usually used for small stone and wooden houses. It is arranged in the same way as a regular monolithic one, but with a laying depth of 50-70 cm. It can only be laid on slightly heaving soils. The construction of a basement or garage with such a foundation is unacceptable.

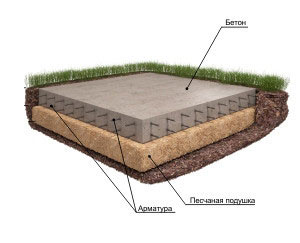

Monolithic base plate

Scheme for calculating a monolithic floor.

Increasingly used in low-rise construction slab foundation. Its use is especially effective on difficult soils: subsiding, heaving, with an increased level of groundwater. Ground shifts in this case do not affect the house: the entire slab is lowered or raised. For this reason, such a foundation is called floating, the house built on it moves with it as one. A monolithic slab reliably protects the house from seasonal deformations and distortions.

The plate, due to the increased area of support, is resistant to loads arising from freezing and thawing of the soil or its subsidence, successfully resists adverse conditions environment. It can be used as a foundation for any houses: monolithic, frame, brick, wooden.

For ordinary country house a monolith thickness of 40 cm is sufficient. Of these, 10 cm are buried in the ground. Technologically, the slab foundation is formed as follows:

- a foundation pit is being built, its bottom is compacted, sand and gravel are added;

- waterproofing is laid on the backfill, which is poured with a thin layer of concrete;

- a frame of reinforcement is knitted, containing at least two layers rigidly connected to each other;

- the base is completely concreted, preferably in one step, without long breaks between concrete supply.

Concrete calculation scheme

A monolithic slab imposes increased requirements on reinforcement, since bending loads in any direction, and sometimes torsional loads, can occur in it. Reinforcement with a diameter of 12-16 mm is used, always ribbed, for better adhesion to concrete. The fittings must not be dirty or rusty.

The gaps between adjacent rods are 20-40 cm. About 14 m of reinforcement is consumed per 1 m 2 of the foundation. The consumption of reinforcement here is much greater than for other types of foundations. And given that the consumption of concrete is also higher, it is not surprising that the cost of a monolithic slab is quite high.

Like a strip foundation, a monolithic slab can be shallow and deep. The latter requires digging a deep pit, but it provides a high bearing capacity. It is expensive, therefore, in individual construction, a deep-seated monolithic slab is a rarity.

For the device of a shallow monolithic slab, the top layer of soil is usually removed, and instead of it, sand and gravel are added. Resistance to frost heaving is provided by the insulation of the soil around the slab.

The top, smooth side of the slab usually serves as a basement or basement floor. Using a monolithic slab to build a house without a basement or basement is hardly advisable.

- If the soil is strong enough, the groundwater level is low, and the house under construction is light, you can limit yourself to an inexpensive shallow strip foundation.

- Under the same natural conditions, but for a more solid house, especially with a basement or basement, build a deeply buried tape.

- On difficult soils with an increased level of groundwater, it is necessary to build a slab foundation.

It remains to be hoped that the article was able to provide real assistance in your choice.

Every person, even those who are not very familiar with the topic of construction, knows about the need to erect such a part of any construction as a foundation. The foundation created with its help takes on all the pressure produced by the house standing on it, the garage, the bathhouse, etc., and distributes it evenly over the ground - the direct foundation. In the language of professional builders, there are several terms that are used when working with the foundation.

This is usually the name of the component parts of this building. So, the upper part of the foundation, which is clearly visible at the level of the earth's surface, and sometimes it can even rise several tens of centimeters above it, is called the edge or the foundation surface, which is more popular. And the lowest plane of the foundation being poured is called its sole.

Depending on the load of what weight will act on the foundation, the dimensions of the sole and the surface of the foundation may coincide or differ. In most cases, the foundation throughout its entire length and height has the same size and shape. The only exceptions are multi-storey buildings. In these cases, they are significantly expanded, thus achieving a softer and more uniform perception of the load on the base. Several types of foundation are noted: pile, on pillars, tape or monolithic. At the same time, the “slab on the tape” foundation, or tape type, is considered the most popular not only in the field of professional, but also in private construction. More and more private owners decide to independently build certain objects on their plots. Not only garages, bathhouses, summer arbors are erected on their own, but also multi-story houses and cottages. But nothing will work out just like that, and before you start, you need to study a lot of information about it and about the technologies of its organization.

Features possessed by the foundation on the tape and the technology of its device

The foundation for a house, arranged on a tape, involves the installation of a reinforced concrete strip that runs along the entire perimeter of the building under construction, at a depth necessary to hold this particular object. The tape, in accordance with the existing standards for the construction of the foundation, is laid not only under external, but also under internal walls buildings that can also be load-bearing. At the same time, it is necessary to try so that the slab used in laying the foundation has the same cross-sectional shape throughout the entire perimeter. This is important so that the load pressing on the foundation is perceived evenly in all construction sites. However, there are times when the slab may not be laid under the interior walls. For example, when building a small country house or garage. The strip foundation slab can have a smaller cross-sectional dimension when you are building a large one, but cottage, while not using the attic space for arranging an attic room in it.

If there are no other loads on the internal partitions of the house, except for that which is created by the roof and roof installed on the house, then the arrangement of the interior can be avoided or simplified.

Back to index

Where is strip foundation used?

There is a generally accepted indicator of the density of brick or stone walls of a building under construction, which, when raised to 1300 kg per m², clearly requires that tape plate. Plus, it is poured in cases of the presence of a threat of flooding due to uneven precipitation or heavy snowmelt.

It is strongly advised to organize a strip foundation for those homeowners whose site is located on soil that has a heterogeneous structure.

It happens that the site can be filled with sand on the one hand, and interspersed with clay structures on the other. In any case, it will be necessary to arrange a reinforced strip foundation, which can create a homogeneous integral structure. That will help redistribute the load as evenly as possible, and this guarantees the absence of cracks not only in the foundation, but also in the walls of the house. In addition, the territory of your house will be protected from the appearance of various deformations, such as distortions of door and window openings.

Foundations of this type are also resorted to when the owners of the house have a desire to make a basement or basement on the territory of the house. The role of the walls of which will be perfectly performed by a slab poured into trenches under the foundation.

A well-made foundation on a tape can last from 30 to 150 years. The exact period of operation depends on what quality construction material used when laying the foundation of a building. For example, a monolithic foundation, organized on a concrete and rubble basis, will last as long as possible - more than 100 years.

Such data were obtained experimentally. Moreover, it does not require any special preventive and repair work. Is it small cosmetic procedures at the beginning of the spring season, he will not be disturbed. And that is after 50 years of operation.

The strip foundation, which is laid out of brick, can last at best 40 years, since silicate brick, used in such work, is distinguished by the feature of absorbing moisture too quickly and keeping it in itself for quite a long time. This, in turn, adversely affects the quality of the foundation itself, which is easily destroyed. A prefabricated type can be successfully organized under a building under construction, it can last 50-80 years. It differs from the monolithic one in that the concrete slab and blocks here are not poured at the construction site, but are brought from the manufacturer and installed in pre-dug trenches.

Back to index

Types of foundation on the tape and the technology of their construction

Depending on how the device of the tape type of the foundation is carried out, several types of it can be distinguished. It:

- monolithic;

- made;

- brick foundation.

Monolithic type is laid directly on the construction site. This means that the entire process of work takes place near pre-dug trenches. That is, right on the spot, the trenches are supplied with reinforcement, the concrete solution is mixed and the ditches are further filled with it. It is desirable that the entire foundation tape be filled within 24 hours. This allows you to exclude all kinds of splits in the foundation and further displacement of the walls installed on them.

Prefabricated foundations, on the contrary, are built using reinforced concrete blocks, instead of which a factory-made slab can be used. They are delivered to the construction site and assembled using heavy equipment. Since not a single slab and block of reinforced concrete can be installed in the place allocated for them only by the builders. Here you will need to use a crane-manipulator. These blocks and the slab form a kind of cushion for the base. After the slab and all blocks are installed and connected to each other with reinforcement, they are poured with a cement-based concrete solution. This makes the foundation on the tape even more durable and more or less uniform.

Foundation organized by creating brickwork it is not difficult to make bricks in 2, but it is better to use red burnt brick, which, although it absorbs moisture in the soil, is able to lose it much faster in favorable weather conditions. For example, in sunny, dry or windy weather, when the air humidity is below or equal to the norm. When planning construction on a private plot, it is necessary to make a very accurate calculation of the load that will be exerted by the building on the foundation. It will help determine the depth at which it is necessary to organize a strip foundation, both monolithic and prefabricated and brick.

Back to index

Determining the depth of the foundation being laid

The shallow type of foundation is ideal for organizing a reinforced concrete cushion for lightweight houses. Wooden houses are usually installed on it, having foam concrete walls and ceilings, frame houses. Sometimes it is allowed to install on a shallow type of strip foundation and a small stone house with one floor. The maximum depth of this type of foundation is 50 cm. In this case, the stage of reinforcing this foundation cannot be skipped.

If in your case the house will have heavy walls and ceilings, and the groundwater level in the area under the house is quite high, then it is recommended to build a deep foundation. A more accurate depth of the trench for such a foundation can be determined after you calculate the level of groundwater. In this case, the slab (the sole of the concrete foundation) should be laid 20-30 cm deeper than the result obtained. Having chosen one or another type of foundation on the tape, it should be remembered that they are recommended to be laid only in the warm season. Otherwise, the building material used in the work will lose a number of its original qualities, in particular, the level of strength and stability of the foundation will seriously decrease. And at the same time, the building standing on it.

The most popular materials for a tape-type device are:

- reinforced concrete;

- rubble concrete;

- reinforced concrete foundation block or slab;

- brick.

It will be possible to choose which of the above options to use when building your house only after the project plan is ready and its calculation is processed, in accordance with the characteristics of each type of foundation on the tape.

Back to index

Concrete type of strip foundation

At the time of preparing the solution for this type of foundation, large stones are added to the sand-cement mixture. With the help of which it is possible to achieve a high-strength structure that will be suitable for building houses on a site with light sandy or rocky soil. You can choose the width of the trench for this kind of foundation yourself, here it would be advisable to evaluate the average load that will be exerted by the structure on the foundation. It can be 30-150 cm.

It also assumes the organization of a sand and gravel cushion, the thickness of which should not be less than 10 cm. And concrete is already poured on it or a slab is placed on it, if we are talking about on a tape. The advantage of such preparation of the base is that with the help of a mixture of sand and small stones, the soil surface under the foundation is leveled, and the concrete mixture and each reinforced concrete slab are laid correctly and conveniently.

The technology of building private houses dates back many centuries. During this time, natural selection has taken place. the best views their foundations. At the same time, the development of building technologies offers more and more new options with improved characteristics.

Among the most widely used, two types occupy a special place - strip foundation and slab foundation. Each of them has its positive and negative sides. At the same time, users and novice builders often ask themselves the question - what is better - a strip foundation or a monolithic slab. Let's try to clarify this issue.

The best foundations are monolithic and tape

Strip foundation - design, types, features

The strip foundation is the most famous. It is used by many builders as the main type when installing buildings made of wood, brick or sides, the height of which does not exceed 2-3 floors. This type of foundation is valued by builders for the following properties:

- high performance;

- relative ease of installation;

- the possibility of making your own hands.

Depending on the location of the tape, a deepened, shallow and non-buried strip foundation is distinguished.

Regardless of the specific type, structurally, this type of building base can be represented by a closed structure of a trapezoidal or rectangular section. The strip foundation is located under all the walls of the house and. Each option for hardening contains steel reinforced cores inside. This makes it possible to overcome the serious bending load that occurs during spring soil deformations. The advantages of a strip foundation over a slab foundation are in simplicity and low cost.

Buried strip foundation

When choosing one or another type of foundation for a house, it is necessary to be well versed in the main differences of each of them. It is impossible to unambiguously choose a strip or slab foundation without analyzing the operating conditions of the house, the financial capabilities of the future owner and studying their features.

It is a concrete belt located below the level at which the soil freezes through in winter. This minimizes the effect of soil heaving on the base of the house, which prevents cracking and deformation. This species can be used only at a sufficiently low level of groundwater.

shallow foundation

For buildings of light weight on calm soils, the type of strip foundation, which has a minimum depth, is more suitable. When choosing a slab or strip foundation in this case, the first type will be economically unprofitable as the most costly. The installation technology of a slightly buried base is simple, does not require high qualifications of workers. Doing it yourself is not difficult. The consumption of the main components of the mixture is also not high.

Unlike the previous species, the shallow version is often subjected to severe pressure from below during the freeze-thaw cycles of the soil. This can adversely affect the integrity of the structure of the house and the integrity of the tape. On such a basis, it is not recommended to build heavy buildings made of bricks or blocks with more than one floor. And in this case, the choice of a slab foundation or a tape with a small occurrence will be in favor of the latter option.

Unburied Tape

This option is located directly on the soil surface or in some cases can even be raised above it. It is not advisable to make a choice of an unburied tape or a monolithic slab, since the characteristics of these types are completely different. This will be discussed in more detail below when getting acquainted with the slab type of foundation and its variant, which can be called a slab on a strip foundation.

With sufficient geometric parameters of the base, even quite massive structures can be erected on it. Unlike previous species, groundwater and winter heaving do not have any effect on it. But with this option, it is impossible to build a basement, a basement, which will lead to large heat losses through the floor.

The monolithic slab has the best qualities of the available types of house foundations. Due to the large area, the load during heaving of the soil is distributed evenly over its entire area, so that the structure of the house does not suffer. No wonder the second name of this option. This is especially true on weak soils with high level deformations and high groundwater.

You should not even compare the strength characteristics of a strip foundation with a monolithic slab. The first type will definitely lose. If your goal is to build a massive brick or block house, it is better not to find a monolithic slab. But with all the advantages, it also has a number of significant disadvantages:

- First of all, it is a large amount of ground work. To fill a monolithic slab, it is required to make a pit, albeit of a small depth, but located under the entire area of \u200b\u200bthe house with a release beyond the walls of 0.5 meters.

- the second important aspect is the high final cost of the foundation slab. The increased consumption of reinforcement and concrete will certainly affect the financial support of construction.

The above aspects do not allow you to unequivocally indicate which foundation is better than a strip or slab. The strength advantages of the latter compete with the simplicity and lower costs of manufacturing the former. Under certain soil conditions, the choice of a strip foundation or loses its meaning due to the impossibility of arranging the latter. Other things being equal, not many experienced builders will choose the foundation slab due to the above features.

Successful Consensus of Two Kinds of Foundations

Among the total number of bases for residential buildings, one type stands out separately, which can be called a monolithic slab on a strip foundation. It successfully combines all the advantages of each of the options described above. Of course, it will not work to make a strip-slab foundation without a significant investment of effort and money, but as a result you will get the best option out of all available.

Deciding which better foundation tape or monolithic, you should be aware that even when using the latter, the construction of a basement and a basement floor is very difficult. It is also difficult to lay communications under a monolithic slab - the difficulty of access will not allow for repair work. At the same time, even when groundwater, lying under the surface of the soil, a monolithic slab will always help out.

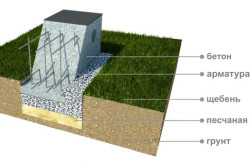

Structurally, a monolithic slab over a strip foundation can be compared with a bowl turned upside down, which with its walls is deepened into the ground, and at the bottom holds the entire mass of the built house. The manufacturing process of this type can be represented by the sequence of the following steps:

- territorial marking of the building site is carried out, taking into account the dimensions of the future building;

- soil is removed to a depth of about 40-50 cm over the entire area of \u200b\u200bthe slab on a strip foundation. In this case, it is necessary to obtain the most flat horizontal bottom. This can be achieved only by sampling the soil, backfilling can provoke the subsequent washing out of the loose substrate, which is fraught with unnecessary stresses in the foundation structure.

- Along the perimeter of the future monolithic slab, it is installed from flat sheets or plank boards. From the outside, frequent supports are required in increments of 500-600 mm.

- a ditch with a width of at least 400 mm and a depth of about a meter is dug under the future walls. Similar trenches are being dug in parallel bearing walls with a step of 3 meters or under load-bearing partitions. If one of the dimensions of the house exceeds 6 meters, the number of such ditches is proportionally increased.

- a monolithic slab on a strip foundation will gain maximum strength only when using a reinforcing frame. It is made from round steel rods with a corrugated surface. The diameter of the bars is selected depending on the operating conditions of the base. Rods with a radius of 7 or 8 mm are optimal. The foundation tape with the slab will be as strong as possible, provided that there are a sufficient number of reinforcing layers. Each of them should be a grid with cells of 15x15 cm. Reinforcing frames are also laid in the ditches.

- It is impossible to obtain a foundation of the “slab on a tape” type without the use of large volumes of high-quality concrete mix. To make it in such a volume with your own hands, even when using an electric mixer, will not work. It is necessary to purchase ready-made concrete at specialized plants in the amount necessary for the simultaneous pouring of the entire monolithic slab in one go.

- Regardless of what type of base - tape or monolithic slab is supposed to be installed, get concrete structure good quality impossible without the use of vibratory compaction of the liquid mixture. This is done using a special construction device - a vibrator. With one-time work, it is not advisable to buy it. It can be rented from specialized organizations. Thanks to the use of such a device, the density of concrete of a monolithic slab increases significantly, air bubbles are removed from it.

- After pouring and sealing concrete mix must be kept unloaded for at least two months. During this time, the monolithic slab will acquire maximum strength characteristics and dry out.

With this review, we tried to consider various foundations: a slab or a tape, which is better or worse in certain conditions. It is definitely impossible to recommend a certain type - it all depends on the specific operating conditions.

Pouring a slab onto a strip foundation is a fairly simple procedure. Before starting work, it is necessary to calculate its thickness, have a clear idea of the structure of the material, its waterproofing and additional work on insulation.

Just follow simple rules when doing work.

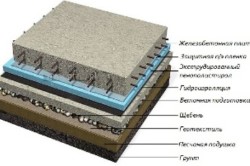

Training

Preparing a pillow under the stove. To do this, the soil is removed by 30 cm. It can be removed to the base of the strip foundation. The first layer is geotextile. It must be laid so that subsequently the sand does not mix with the soil. The next moment is the laying of the pipeline. it sewer pipes and plumbing, after which the pillow itself is filled up by 20-30 cm, consisting of crushed stone and sand.

Formwork and reinforcement

Formwork is made of wooden panels to the height of a monolithic slab.

Formwork is made of wooden panels to the height of a monolithic slab.

A reinforced frame is being made. This will require rods with a diameter of 12-16 mm. A mesh is made of rods, the size of the edge of the cell is about 30-40 cm. It is necessary to know the severity of the structure under construction: the heavier the future house, the smaller size cells. The grid is laid out in two floors and fixed with vertical jumpers made of reinforcement with a diameter of 8-10 mm by welding or tying with metal wire. It is also worth considering that the first row of the grid should not lie on the ground. It must be raised by 5 cm. Brick, crushed stone or pieces of blocks can be used as supports. The structure must be as strong as possible to prevent its displacement during pouring.

fill

Direct pouring with concrete. Everything is poured slowly and carefully. It is desirable to do all the work at one time, in order to avoid uneven fixing of the material. Next, you need to level the surface. It takes about 28 days to harden the foundation. To enhance waterproofing, the entire surface can be treated with a special resin mastic.

The foundation is ready. You can start building walls.