Manufacturers offer a fairly wide range of finishing materials.

To save a little on wall alignment, rooms such as a bathroom, kitchen or corridors can be paneled. In addition, they look quite aesthetically pleasing and, unlike wallpaper, do not wipe, are easy to clean and last much longer.

To meet the needs of various categories of customers, wall panels are available in various sizes:

- production material;

- color design;

- form;

- size.

All types of wall panels have their own distinctive features and advantages for installation in residential premises.

Shape and size

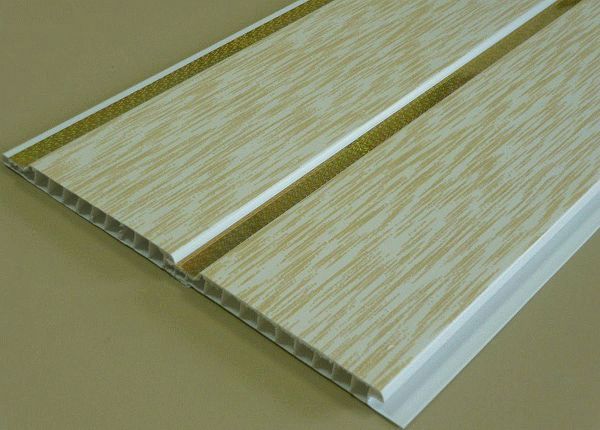

- Type-setting panels, or lining. The width of the type-setting panel is from 10 to 30 cm. The length is up to 6 meters, and the thickness is 8 - 25 mm. For more convenient installation, the panels are produced with a tenon-groove assembly system.

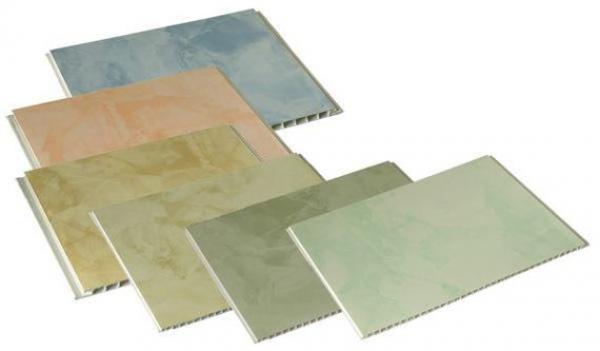

- Square. The difference in sizes and colors allows them to be combined with each other and lay out a nice ornament on the wall. The mounting system for such panels is the same as for type-setting.

- Sheet. Outwardly and in size, they look like sheets of hardboard familiar to everyone. The thickness of such panels can be 3 - 6 mm. This type of panel can be glued to the wall in the rooms, if it is flat enough for this.

Types of wall panels

Based on the properties of the material used to produce the base and top layers of the panels, they may be susceptible to moisture.

Moisture resistant include:

- wood panels, surface treated special coating, for example, wax;

- laminated on both sides;

- plastic, or coated on both sides with plastic;

Moisture resistant:

- chipboard panels;

- fiberboard panels;

- MDF panels;

- Non-laminated.

Now a little more detail about the types of wall panels.

MDF panels

These panels are made on the basis of pressed wood dust (or fine shavings). Outwardly, they can resemble solid wood due to their thickness - about 16 mm.

Properties:

- these panels are easy to work with, they do not crumble and are easily cut;

- increase the thermal insulation and sound insulation of the premises;

- panels tend to expand somewhat when heated;

- manufacturers indicate on the packaging the degree of moisture resistance of the material;

- There are types of refractory MDF panels.

Such panels can be used to decorate a corridor, a loggia (balcony) or an office.

Plastic panels

Material properties:

- natural material;

- good sound insulation;

- the surface of the panel is antistatic, wear-resistant;

- on top they can have a lacquer, glossy or matte silky finish.

- high moisture resistance, including at the joints, which allows the panels to be used in very damp rooms.

- do not require special care and are easily washed from pollution;

- hygienic.

Such panels are used for finishing the interior of a residential building and, sometimes, external ones.

This type of finishing material includes products made of natural wood and finished with natural veneer.

For production are used:

- cedar;

- maple;

- alder;

- ash;

- beech, etc.

In order to increase the performance of wooden panels, they are varnished or waxed. But before that, they are pickled.

Material properties:

- environmental friendliness;

- long service life;

- the tree breathes.

They are suitable for finishing hallways, corridors, technical rooms.

Chipboard panels

Chipboards are based on sawdust and shavings, which are pressed using binders. chemical compositions. Therefore, they are considered unacceptable material for finishing living rooms.

Due to its high ability to absorb moisture, it is not used for finishing bathrooms, kitchens and balconies.

They can serve as an optimal and inexpensive finishing option for auxiliary dry rooms.

cork panels

Such panels are usually two-layer. The bottom layer is made of pressed cork chips. The top decorative layer can also be made of cork wood crumbs, but with the addition of bark, or be a solid layer of cork tree bark. To enhance the qualities of the material, it is covered with wax.

Material properties:

- the cellular structure of the cork, which is able to increase the thermal insulation and sound insulation of the premises;

- characteristic lightness of the material;

- strength and durability;

- elasticity;

- hypoallergenicity;

- antistatic;

- fungus resistance.

Given all the positive qualities of the material, it will be ideal for the kitchen and dining room. It is absolutely eco-friendly.

acoustic panels

The material is made on the basis of fiberglass. The thickness and surface of the panel are different and have a directional application - increasing the acoustic properties of the room.

Mirror plastic panels

They are made on the basis of polystyrene and covered with a protective film. These wall panels also have a directional use - for finishing the foyer of hotels, bars, restaurants, etc. Due to their properties, they bend well and are suitable for finishing rounded surfaces, such as columns.

Sandwich panels for interior decoration

These panels have two layers of polymer sheets, inside of which there is a heater.

Basically, the outer walls of sandwich panels are made of polyvinyl chloride. The inner layer can be from:

- polyurethane foam;

- basalt wool;

- expanded polystyrene;

- polyvinyl chloride, etc.

Extruded polystyrene foam is considered the best insulation.

Material properties:

- ease;

- low thermal conductivity;

- resistance to various temperature conditions;

- high fire resistance;

- strength;

- moisture absorption is almost zero.

Compared to conventional plastic panels, the price of wall sandwich panels is quite high, but it is justified. high quality material, including the presence of insulation.

The outer layer of sandwich panels, in addition to PVC, can be made:

- From metal;

- magnesite slabs.

All constituent materials are glued together.

The outer side of the material can be smooth or decoratively profiled. For interior decoration premises apply:

- Decorative siding panels;

- Timbered panels.

For interior decoration of residential premises, sandwich panels are used to increase thermal insulation.

Methods for mounting wall panels

Depending on the material from which the wall panel is made, is selected suitable way mounts.

- Glue. If the walls of the room are even, and finishing material not too heavy, you can use glue for MDF or fiberboard. The glue is applied to the wrong side of the panel in zigzags, after which the material is pressed against the wall surface.

- Mechanical fastening to the crate.

- Self-tapping screws fasten the panel in the room, which does not change the modes of humidity and temperature.

- Clamps to the crate (wooden or plastic).

It seems that repair is a fairly simple task and difficulties can arise only with the work itself. Especially if the experience is not so great. But a lot of problems emerge at the preliminary stage. The fact is that there are many types of finishing materials on the market that could not have been imagined ten years ago.

Huge popularity has earned wall panels for interior decoration, which have a wide range of textures and colors. They are very easy to install, which allows you to carry out all the work without the involvement of unauthorized persons.

Currently, there are three main modifications of this material. They differ in their technical characteristics. Each specific type is selected based on the premises, and has specific advantages. Naturally, the choice of wall panels for interior decoration will also determine the final interior of the object.

Decorative wall panels are very diverse, they can become not only a practical wall decoration, but also a highlight in the interior.

Decorative wall panels are very diverse, they can become not only a practical wall decoration, but also a highlight in the interior. On a note! Wall panels- often decorative, but there are products that relate to structural elements. They are used inside the house and apartment, but their main task is to create partitions and walls.

Type-setting rack panels

These products have the following properties:

- The length of the slats ranges from 2.4 m to 3.7 m.

- Width - from 12.5 to 30 cm.

- Thickness - from 8 to 10 (12) mm.

- Production material - chipboard, MDF, fiberboard and PVC.

Rack panels are most often used in small rooms or when the object has many internal and external corners.

For the highest quality installation, the technology of creating crates is used. The material for its creation can be a wooden bar or a metal profile. Clamps are used as fasteners, as well as self-tapping screws that are screwed into the groove. Decorative panels for interior wall decoration, made in the form of rails, create a special flavor of the house.

Fixing to each other is carried out in two ways:

- Spike + groove.

- Groove. But additionally, you need to use special tabs.

For ease of use, the product line includes additional elements that are used to hide joints and create uniform transitions.

Finishing panels for walls in the form of a sheet are the largest among this type of material. Their size is: 122 * 244 cm, with a thickness of 0.6 cm. They are made of PVC or fiberboard, which is pre-impregnated with various resins.

This product has a structure that is multi-layered. A drawing or imitation of natural material (wood, stone) is applied to the front surface. Glue is used for installation. They are very convenient because they allow you to work immediately on a large area.

Plates

These products have a square shape and two standard sizes:

- 30*30 cm;

- 98*98 cm.

They allow you to embody the most daring design decisions, because it is the plates that make it possible to lay out various combined drawings (reliefs). Fasten with glue or clamps to the crate. They are connected to each other in a locking way. The material used is MDF, chipboard, PVC.

Finishing the bedroom with decorative tiles

Finishing the bedroom with decorative tiles On a note! As you can see, wall panels are made from similar raw materials. Therefore, different types are easily combined with each other to decorate a house or apartment.

Advantages and disadvantages

You can not ignore the wide range of advantages that decorative wall panels have.

- Long service life. In principle, if you follow the rules for their installation and maintenance, then they can be considered literally "eternal". Most often they are changed in order to update the interior.

- Ease of maintenance. There is no special set of measures that are required to be carried out in order to maintain their original appearance. They practically do not react with chemicals. But another thing is very important - to choose high-quality material.

- Safety. Decorative panels for interior wall decoration are environmentally friendly. They do not contain substances hazardous to health, therefore they can be used even in medicinal and educational institutions. Particularly valuable are products that are made on the basis of wood fibers.

- Ease of installation. Indeed, all the work is done literally by hand. You also don't need to buy expensive tools. Of course, with a complete lack of building skills, the process may seem complicated and incomprehensible.

- Diversity. You can choose the best option.

- Versatility of use. Modern options These products will find their application in all types of premises. They allow you to create additional sound and thermal insulation, which makes them indispensable in many situations.

- Economic component. Almost all types of wall panels are moderately priced. And if you take into account their durability, then the costs become minimal.

The list of advantages is impressive, but there are also some disadvantages. In most cases, they are associated with the notorious human factor. Namely:

- Before use, be sure to keep the material in the room where the repair will be made. Ignoring this action is a direct path to a decrease in service life.

- PVC products are very demanding for transportation and installation. On the one hand, the cellular structure of the material is a guarantee of their excellent qualities, and on the other hand, it creates the possibility of mechanical damage.

- Plastic options, when burned, emit suffocating smoke.

Panel material

Everyone wants to see in their home only the best options for finishing products, which undoubtedly affect the overall atmosphere of the home. It is already clear that cladding panels for interior wall decoration can be made from completely different raw materials. It can be modern plastic, as well as wood that has earned its fame.

On a note! There are options when several types of raw materials are combined. This was done with one goal in mind, to give the products additional qualities that are needed.

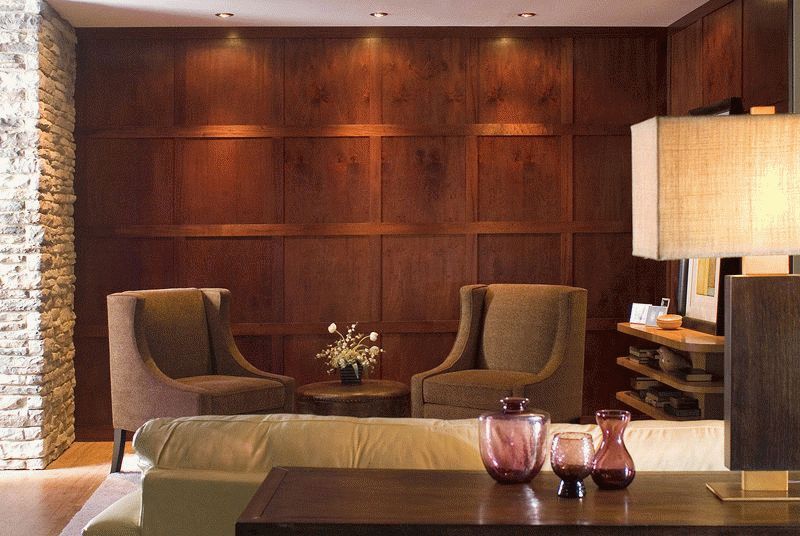

natural wood

This classic material has been popular for many centuries. But, if earlier wood was used due to the lack of competitors, now it is solely due to the fact that it has many positive qualities. And the first of them is naturalness. In addition, only a tree can create a truly warm atmosphere in a room.

Decorative wood panels

Decorative wood panels The raw materials for decorative wall panels are the following types of wood:

- Maple.

- Cedar.

- Alder.

- Bamboo.

Many people think that the tree is quite demanding to use. It really is. But we must not forget that recycled material is used for the production of facing elements. And often - veneer. This greatly simplifies all requirements.

Such panels for wall decoration in an apartment are available in rack and slab configurations.

On a note! This option is considered the most expensive. Especially if you take into account products that are made from valuable veneer. With bamboo - it turns out another interesting story, it is fixed on the parts manually.

Particle boards

Speaking openly, this material is a waste of woodworking industries. But, using pressing, it is possible to obtain a chipboard board, which becomes an indispensable building and finishing material. Probably everyone is familiar with chipboard. Therefore, a natural question arises, how can one obtain from it decorative panels for walls? It seems that their unattractive appearance can no longer be corrected. Although everything is simple. They are simply covered in plastic.

This method made it possible to make a breakthrough in the manufacture of wall panels. After all, it became possible to create a wide range of options that will differ in their structure and color.

There is an opinion that such plates emit a harmful substance that adversely affects the general well-being of all residents of the house. Indeed, the adhesive composition that holds the fibers together cannot be called completely safe. But there is no particular cause for concern.

- Firstly, the content of all components complies with strict international standards. Of course, if you buy decorative wall panels from a reliable manufacturer.

- Secondly, there is a layer of plastic. It serves as reliable protection.

That is why chipboard-based panels are used everywhere, except for rooms with high humidity. If natural wood is varnished and waxed, then in this case, this approach is useless.

Advice! It should be borne in mind that such products have significant weight and are produced in the form of plates. Therefore, it is quite difficult to work with them, it is better to do it together.

fibreboard

Not to be confused with chipboard. These materials are similar, but have a different structure of raw materials and differ in production technology. Therefore, fiberboard is a completely safe and environmentally friendly material. It is possible to obtain decorative cladding panels from it, which can be of any type. This explains their popularity. In addition, they have a very low cost, which ensures their ubiquitous availability.

Wall mounting method:

- On the frame. It does not matter what it will be made from.

- For glue. The surface must be carefully prepared and must be dried.

Fiberboard panels have a number of undeniable advantages over other materials:

- The connection takes place depending on the selected option (lock or groove). You can choose the most preferred one.

- Installation is quite fast. In addition, the decorative wall panel may need to be replaced if it has been damaged. With other species, this is difficult to do.

- Light weight, but resistant to various influences.

There are the following types of finishes:

- laminated;

- lined with cloth;

- covered with veneer;

- painted.

On a note! There are many advantages of such a material, but there is one significant drawback - the fear of moisture. But, unlike chipboard, it does not manifest itself so much.

MDF

At first it may seem that MDF and fiberboard are brothers. But the first option is even more modern and also more expensive. Cladding panel obtained from such material acquires the following properties:

- Excellent soundproof performance.

- Increased thermal insulation.

- Fire resistance.

- Moisture resistance.

- Resistance to mechanical impact.

MDF is covered with the same types of finishing raw materials as fiberboard.

PVC

More recently, this option was the most common, until it was replaced by MDF and fiberboard. Now, when new technologies have come, PVC wall panels have again begun to win their place in the market of finishing products. What are they good for:

- Do not collapse under the influence of moisture. They can be used for dressing rooms, bathrooms. Great for public places that have air circulation from the street.

- Very durable. It is quite difficult to spoil such a product.

- Amenable to decoration. And also they are covered with various patterns.

- They have a low price. It is lower than other species.

PVC wall cladding products have opened up a new world of possibilities for designers. Now you can build houses and finish them inside so that it will seem that everything is made of natural wood or stone. And, in fact, everything will be made of plastic.

Other types

Wall types of panels do not end there. They are also made from other raw materials:

- Glass. This is a great option when you want to make the most picturesque drawing or photograph. Do not be afraid that such elements for wall cladding can be easily broken. Although, they need better care.

- Gypsum vinyl. Structural elements that are made of such material are characterized by excellent reliability and a wide choice of textures.

- Metal. Decorative metal panels - a new word in modern design. It is possible to obtain a surface that resembles something fantastic.

A little about the selection rules

- Wooden types - suitable for living and sleeping rooms, living rooms. They will be able to emphasize the richness of the interior, and especially when the room is furnished with good furniture.

- The glass version is a rather unusual solution. But great for creating a picturesque accent. Looks good in kitchens.

- Plastic elements - feel great everywhere. But it is better to avoid them when you want to create a classic version.

- Metal products are simply created for something cosmic, free, but cold. Although shades allow you to create different feelings.

Knowing what wall panels are, you should remember the main thing. It lies in the fact that there is no need to chase newfangled trends, it is better to create something that will please with its individuality.

One of the most rational alternatives to reorganize the premises, with minimal financial investment in facing material and repair work, is to use decorative panels for interior wall decoration. Today, their considerable variety in terms of release forms, material specifics, as well as price scale, allows you to with full confidence to assign decorative wall panels a leading position in the building materials markets.

The selection of the material from which decorative panels for interior wall decoration are made is one of the most relevant and important stages in the implementation of restoration repairs in the room.

For example, plastic decorative wall panels will be the best option when decorating such rooms as − bathroom or kitchen. And the design of the premises with wall panels with lamination under a tree (or from MDF) will no doubt look much more harmonious if they are mounted in the living rooms of private wooden buildings.

The basic components in the formation of decorative panels for surface finishing are:

- PVC - polyvinyl chloride, which is excellent for rooms with high moisture content;

- Chipboard - chipboard, which, on the contrary, is recommended to be installed in rooms where the moisture content of the air is low;

- MDF or fiberboard - a finely dispersed fractional and fibreboard, which is also not recommended for use in rooms with high humidity, however, the characteristics of this material have higher quality indicators than those of chipboard;

- Natural wood is one of the most expensive and high-quality cladding, compared to those presented a little higher in this article. He (material) is not only an exquisite and presentable design solution for interior wall decoration, but is still in high demand in the construction market of finishing materials;

- Laminate or veneer - thin sheets of wood, with a thickness of 0.1-10 mm, for finishing not only floors, but also walls, such a kind of alternative to natural wood;

- 3-D panels made from various materials or their combinations. There are three main layers in their root structure: basic - gypsum with a reinforcing mesh, or MDF, aluminum, etc.; the second - a relief layer (created from gypsum, plastic, wood and other components), and the third - a fixing layer - consisting of PVC film, enamel, or veneer or leather.

Decorative panels for interior decoration of wall or ceiling surfaces according to the release forms are made in the following variations:

- Sheet - with typical dimensions of 1.22 x 2.44 x 0.06 m;

- Tiled or square - with dimensions from 30 x 30 cm to 100 x 100 cm;

- Rack - with a length of 90-300 cm and a width of 13-30 cm, with a thickness of 0.8-1.2 cm.

Most of these types of decorative panels are fixed to the walls of the room using special glue (the so-called "liquid nails"), or on self-tapping screws or ordinary nails - on the surface of the wall itself, or on the crate (mounted from wood or metal profiles, while focusing on selected panel material).

Aspects of selection and scope of decorative panels

As a rule, any decorative panels for interior decoration must meet the following basic technological requirements for them:

- Possess elasticity and plasticity, and at the same time have good strength (hardness).

- Do not react to temperature changes and be fire resistant.

- They must be moisture resistant and made of environmentally friendly material.

- Be resistant to cleaning agents and easy to install.

- Using decorative panels as a finish for interior walls, you can eliminate several problems at once:

- Hide (or vice versa, smooth out) construction flaws in the surface of the ceilings or walls of the room.

- Under them, you can easily hide all the cables, electrical wiring, water pipes, ventilation shafts and other communications.

- Wall decoration with decorative panels can easily, with huge savings in money, replace natural finishing materials, because. Basically, they are imitated both under a tree, and under a brick, and even under a stone, as well as other building facing structures.

- Installation of walls using decorative panels increases heat and sound insulation in the room.

Thus, finishing the wall surface with decorative panels is not only cost-effective, but also very multifunctional in terms of its textural properties and the quality of the finishing material produced.

Modern decoration with decorative panels on ceilings, walls, columns, arches and other partitions has found its application in ennobling such premises as:

- clothing, footwear and other retail stores;

- business offices;

- foyer of hotels, hotels;

- public facilities and buildings;

- individual buildings and apartments;

- shooting pavilions and theatrical scenery;

- bathrooms and kitchens.

Characteristics of modern finishing decorative panels

At its core, the composition of most high-quality finishing panels of the fiberglass variety contains components such as:

- fiberglass (fiberglass);

- natural stone powder;

- dyes;

- polyester resin.

Different materials can be used for interior wall decoration in different rooms. Each species has its own characteristics, cost, appearance. An excellent choice for different rooms are special wall panels for interior decoration, which have a great appearance, imitate a variety of exquisite, unusual materials, and are easy to install, which even a beginner can handle.

The use of panels in conjunction with the crate makes it possible to hide various flaws, defects on the walls that cannot be eliminated by standard alignment. A photo of such panels is presented below in in large numbers, and in different interiors they look great. Decorative panels are produced from different materials, but plastic products are most often chosen, which are reliable, high-quality, attractive and inexpensive.

For their production, different types of materials are used. Since they are intended for use in residential premises, they are environmentally friendly, therefore they cannot cause any harm to residents of an apartment or house. In the selection process, it is important to pay attention not only to the material of creation or the design of products, but also to their colors, appearance, since decorative panels for interior wall decoration should fit perfectly into the existing interior.

Rack

They are represented by small boards that are made of PVC or other popular materials. As a rule, their length varies from 240 to 370 cm. Due to large selection lengths, it is possible to select products suitable for a certain wall height. The width can also be different, since it varies from 12.5 to 30 cm. The thickness starts from 8 mm and ends at 12 mm. Rack panels made of PVC or other materials are used, usually for low walls, and are also considered ideal for small rooms.

They are mounted using a frame created in advance on the walls, and metal profiles or wooden slats can be used to create it. The elements are connected to each other with special grooves and spikes, which they are equipped with even during the production process. These fasteners are located at the end of each part.

They are fixed to the frame with self-tapping screws or special brackets, and in the second case, you must have a special tool at your disposal - a construction stapler. If there is a need to make hidden installation, then clamps are used.

Elements can be mounted both vertically and horizontally. It is allowed to use a special way - a Christmas tree. Most often, PVC or chipboard, as well as MDF, are used to create rack products.

leafy

They are considered the most convenient elements for prompt, high-quality installation. They are ideal for large spaces. Their dimensions are significant, and the thickness can even reach 6 mm.

Sheet elements are multi-layered, and the most popular are details that imitate a variety of exquisite, unique materials. They can be made of PVC or other raw materials. Their photos can be easily found on the Internet. Installation is carried out with the help of glue, but among themselves they are fixed with the help of special moldings. It is allowed to use them even in the case of preliminary creation of the frame.

Wooden

Wall panels for interior decoration, created from wood, can have different shapes and sizes. They are available both smooth and with a unique embossed pattern. For each individual interior, the most optimal and suitable option is selected.

To create them, oak or larch, cedar or alder wood is most often used. If cheap material is used, then unique technologies are used in the production process that provide imitation of expensive, refined wood. For this, special compositions are used that ensure the formation of darker fibers and an unusual texture.

Wooden elements are considered an excellent choice for any premises in residential real estate, and this is due to the following parameters:

- ecological purity due to the use of natural, safe components;

- if you choose a material that is impregnated with special moisture-resistant compounds in the factory, then it can be used even in rooms with high level humidity;

- presented wooden panels in different types, photos of which are located on the Internet, so for each room the optimal material is selected to create the coating;

- wood is considered a traditional material, the texture of which fits perfectly into a variety of interior styles, so a truly bright, unusual finish is guaranteed;

- the cost of such products may be different, since it depends on the raw materials used, however, for each person it is possible to choose the option at the best price.

The disadvantages of products formed from wood include the lack of good resistance to moisture or fire, if special protective coatings were not applied to them during the production process.

Cork

Cork panels are an excellent choice for any room. They have an incredibly large number of advantages, which include:

- environmental friendliness, since only safe components are used in the process of their production, as well as cork tree bark, which is considered high-quality and unique;

- from this material, products are obtained that are distinguished by high thermal and sound insulation parameters;

- seeing such panels in the photo, each person will be convinced of their attractiveness and originality;

- material racks before exposure to moisture;

- elements easily withstand high temperature, and also do not support the combustion process;

- cork is not able to absorb foreign odors;

- it is resistant to ultraviolet radiation or temperature changes;

- Installation is simple, so anyone can handle it.

Cork panels can be not only wall, but even floor. They are equipped during the production process with locking joints, due to which not only the installation procedure is simplified, but also a seamless and even coating is obtained. They are available in different shades, so the creation of an optimal color coating is ensured.

Acoustic

They are most often used in apartments where sound insulation is low. Due to this finish, noise coming from neighbors, from the street or from the entrance is reduced. They are created from different materials, but PVC is most often used for this. Their important parameter is porosity, due to which excellent soundproofing parameters are provided.

The most commonly used insulator is acoustic foam, which comes in a variety of shapes and sizes. It is combined with plastic or other panels, so it is not visible after finishing. In addition to foam rubber, other soundproof materials can also be used, and usually their structure has a higher rigidity index. Installation of such products is easy, and the apartment becomes protected from extraneous sounds from the street or from neighbors.

Plastic or gypsum fiber acoustic panels are extremely common among apartment owners located in apartment buildings. Due to their use, the soundproofing parameters of all residential real estate are increased, which significantly increases the comfort of living.

3D panels

They are also formed from PVC or other popular materials. They fit perfectly into different interior styles, and also have an incredible appearance. They become a unique decoration of any room.

As a rule, such plastic 3D panels are additionally highlighted with lighting, which improves the appearance of the wall. Drawings can be varied, and are selected depending on the room in which it is planned to carry out repair work.

3D panels are created not only from PVC, but also from wood, aluminum, gypsum or MDF. There are a huge number of photos of such panels that differ in images, sizes and parameters. All species are environmentally friendly and attractive. Due to the complex structure, the heat-insulating and sound-proofing parameters of the premises increase. Fastening is usually done using a frame, so there is no need to level the wall surface, so a lot of time is not spent on preparing the base.

Basic properties

PVC panels, as well as other varieties of this material, provide an excellent transformation of different interiors. At the same time, they solve numerous problems that cannot be fixed with wallpaper or other finishing materials. These include the following characteristics:

- various irregularities or other problems are hidden on the base base of the wall;

- elements of communication networks are held behind the cover;

- insulation and soundproofing materials are laid in the crate, which increases the thermal insulation parameters of the apartment, and it is also protected from extraneous sounds from the outside;

- By selecting panels that imitate refined, unique materials, a unique and expensive finish is ensured.

Photos of the finished finish from different panels are presented on the Internet, so you can choose the best option for a concert venue. Additionally, the panels are environmentally friendly and fire-resistant, resistant to moisture and easy to install.

Dimensions

Panels can be presented in different dimensions and sizes. The following types and their parameters are distinguished.

Each option has its own characteristics and parameters, which are described above. When choosing, usually not too much attention is paid to the dimensions of the panels, however, this factor is considered quite important, since it affects the ease of transportation and installation of the material, as well as the appearance of the already obtained coating.

Color and pattern

PVC panels, as well as other types of panels created from various materials, are presented in a huge number of colors and textures. This allows you to choose elements that imitate a variety of exquisite and expensive materials.

For each interior and premises, an optimal color scheme is selected or a separate image is created, which will be formed from panels. When choosing a finishing material, many people initially pay attention to its appearance, since the atmosphere created in the room depends on it.

Soft and calm colors and textures are chosen for the bedroom, and marine motifs are great for the bathroom. For the kitchen, it is desirable to choose bright and cheerful colors. However, in addition, when choosing a color and texture, each person who owns the premises should be guided by their preferences.

Thus, wall panels designed for interior decoration are considered an excellent choice for every room. They are presented in a huge number of types, have many advantages and are easy to install. Therefore, the process of their installation is easily implemented on their own.

Video

Interior finishes with different kind panels.

Photo with options for how wall panels in interior decoration might look

Examples of interior wall decoration with panels of various materials.

Hello. In one of the previous articles, I talked about how wall decoration is done. PVC panels with your own hands. I think it's time to continue this topic and review the interior materials that are on the market.

So, let's find out what decorative materials you can buy today and what characteristics you need to consider when choosing.

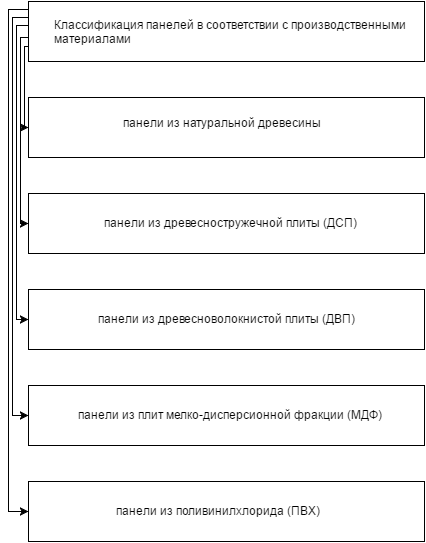

Material classification

While there is a wide range of interior wall panels available for sale, they can all be classified according to the configuration and materials used in the production.

According to the configuration differ:

- oblong shaped laths(thorn-groove connection) with standard sizes: length from 3700 to 2400 mm width from 300 to 125 mm thickness from 12 to 8 mm;

- square shaped plates with standard sizes: from 980 by 980 mm to 300 by 300 mm;

- sheet panels(flat or 3D) with standard sizes 2.44 * 1.22 m with a thickness of 3-6 mm.

Tip: We select the configuration of the finishing material, first of all, based on the configuration features and standard sizes of the walls.

Wooden wall cladding

Wood panels - boiserie (fr. boiserie) are made from coniferous wood - cedar and larch or hardwood - oak, maple, alder.

All these products, in turn, are divided into the following modifications:

- solid wood products;

- multilayer products.

Wooden boards intended for rooms with air humidity up to 60% are treated with decorative impregnations that emphasize the color and pattern of the wood surface. products intended for installation in rooms with excessive humidity are impregnated with protective waterproofing compounds.

To save expensive lumber, the structure of the panels is made multilayer. In multilayer products, hardwood with a beautiful texture is used as the upper thin layer. Some manufacturers use rare and valuable wood veneer as the top layer. The lower layers of the slab are made from less expensive softwood, mostly coniferous.

I will immediately answer the frequently asked question: which is better - a solid or multi-layer plate? Personally, I recommend multi-layer products and there are a number of reasons for this:

- Firstly, multilayer plates are more resistant to sudden changes in temperature and humidity in the room, while solid wood products can warp and crack under such conditions;

- Secondly, the price of multilayer panels is more affordable than the cost of solid wood products;

- Thirdly, due to the use of the top layer of rare wood, multi-layer modifications look more expensive than they cost.

Chipboard wall cladding

Decorative panels made of chipboard are widely used as an inexpensive finishing material. The surface of the product outwardly imitates the texture of valuable wood species.

Similarity with natural wood is achieved in two ways:

- pasting with natural veneer;

- Finished with high quality vinyl veneer.

The basis of the products is a chipboard pressed from fine chips mixed with synthetic resins.

Important: Chipboard products are not very resistant to excessive humidity, and therefore the use of such panels is allowed in rooms with air humidity in the range of 40-60%.

When choosing panels from chipboard, we pay attention to the type of environmental safety of products. This point is very important, since particle boards emit formaldehydes, and an excessive concentration of these toxic substances in the room will negatively affect health and everyday well-being.

According to the formaldehyde emission class, the following types of chipboard are distinguished:

- E 2 - the content of formaldehyde is not more than 30 mg per 100 g of plate weight;

- E 1 - the content of formaldehyde is not more than 10 mg per 100 g of plate weight;

- Super E - the formaldehyde content is less than 10 mg per 100 g of board weight.

Panels made on the basis of boards of type E 1 and Super E are used for interior decoration. Chipboard with an emission class E 2 and products based on it cannot be used in interior decoration.

Products from MDF

Decorative MDF panels are a facing material made on the basis of pressed wood fibers without the use of synthetic resins. A mixture of paraffin and lignin is used as a binder. As a result, MDF does not emit formaldehydes and methanol into the environment, as happens with chipboard products.

The surface of the finishing material is decorated with a vinyl film with an image that imitates the texture of precious wood. Separate modifications of MDF panels have a solid color or are decorated with colored patterns and ornaments.

Important: MDF cladding materials can be installed in rooms with air humidity up to 80%. This is the highest rate among wood-based panels.

There are several reasons, among them:

- formaldehyde emission - class E 1 and below, that is, the material is environmentally friendly;

- over 12 standard options for imitation of wood texture;

- resistance to abrasion and scratching;

- the ability to install with your own hands without the use of special tools;

- the possibility of mounting on the wall without special surface preparation;

- the average price is from 120 rubles per panel 2.7 m long.

Fiberboard panels

Decorative panels made of fiberboard are distinguished by low price combined with high strength and durability. Like MDF products, fiberboard cladding materials are resistant to excessive air humidity, therefore they are well suited for bathrooms and.

A significant disadvantage is that synthetic resins are used in the manufacture of fiberboard, which means that the material is environmentally unsafe. The release of formaldehyde is prevented by a layer of vinyl veneer covering the front side of the panel.

Important: We install ISOTEX panels only on dry walls treated with bactericidal impregnations.

Plastic lining

PVC panels (plastic lining) - this is the most affordable finishing material from what has been listed.

Plastic lining is made of polyvinyl chloride - a polymer material that is resistant to moisture and temperature fluctuations. An important advantage plastic panels is a through-paint. Thus, scratches and abrasions on the plastic lining will not be as noticeable as on the previously listed modifications.

An interesting feature of the material is the hollow structure. That is, along the entire length through hole with thin partitions that act as stiffeners. Thanks to this device, the material is lightweight and exerts an insignificant mechanical load on the surface being trimmed.

What to choose

So I'm in in general terms talked about what kind of panels for wall decoration. There is a natural question, what to buy?

From personal experience for finishing residential premises I can recommend MDF panels:

- Firstly, they look no worse, and maybe better, than natural wood products;

- Secondly, this finishing material is environmentally friendly;

- Thirdly, MDF panels are not as expensive as wooden lining.

For lining bathrooms and other rooms with excessively humid air, I can recommend plastic lining. Not the cheapest PVC lining will still be many times cheaper than wooden counterparts and at the same time it will look good and will not be afraid of moisture.

Conclusion

So, I talked about the main types of materials that are used for wall paneling. Are there any questions that need clarification? Watch the video in this article, after which you can leave your comments.