formwork

ceramics

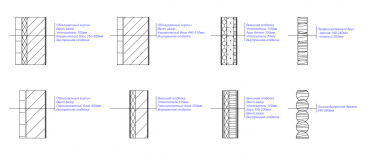

Comparison of various materials and their combinations in terms of thermal conductivity:

What to build a house from?

Before starting construction, you need to decide what a country house is for. Conventionally, country houses can be divided into two broad categories.

Seasonal houses. They are designed mainly for the summer period of residence and for an ambient temperature of 0 ... -5 ° С. The walls of such houses are made in a frame design, from a bar with a thickness of 100 - 150 mm, from rounded logs of small (up to 220 mm) diameters. Due to the low level of protection of the walls of such a house from heat loss, the cost of construction is low.

Polyethylene floats

The last part, and not least, consists of the floats. Made from high density polyethylene, multiple quality plastic, these floats keep everything stable. The placement and positioning of the floats simply balances the weight of the frame and its interior.

By remaining hollow on the inside, they improve the flotation of the house. The principle of three-layer development is found in high-performance shipbuilding and in particular in performance clusters. Technical and playful report. If the work of saving energy has become the accepted logic, more and more people are realizing the importance of maintaining their health by choosing ecological, bio-resource, natural or healthy building products. Healthy materials that do not require a lot of energy for their production and transformation, but above all do not emit harmful substances throughout their life.

Some typical wall options for such houses:

Houses for permanent residence. The name speaks for itself and implies constant heating in the winter. They are designed for outdoor temperatures down to -30°C. Such houses can be both wooden and stone.

People in today's industrialized countries spend about 80% of their time The air contained in various private or public spaces contains numerous air pollutants, some of which enter the deep bronchi. Housing is becoming more airtight to save energy. Buildings are veritable watertight egg cases, which encourages the development of micro-organisms, molds and fungi, the true vector of asthma and respiratory problems. ventilation is also a solution, but in contrast to the fact that it cools the building in winter and heats it up in summer.

Walls wooden houses year-round living are made of profiled or sawn timber from 200 mm and above, with or without insulation, from rounded or chopped logs 240 - 280 mm.

Stone houses of permanent residence are also built using different technologies: monolithic houses in fixed formwork, stone houses from gas blocks (gas silicate blocks), bricks, warm ceramics, expanded clay concrete blocks.

Ventilation and dual flow handling require regular maintenance that no one does unless restricted. Respect for the health of residents and the environment means choosing ecological building by choosing natural materials adapted to regions whose bioclimatic conditions and locations vary greatly.

Aerated concrete house

The patio is an extension of our home, a link between home and garden. The purpose of a balcony is to combine utility with a harmonious visual aspect in addition to adding value to the home. A well-designed space can be the perfect place to relax, socialize, and even garden. Depending on your needs and desires, you can create a unique place.

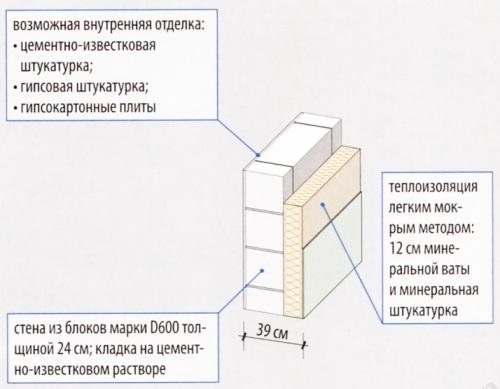

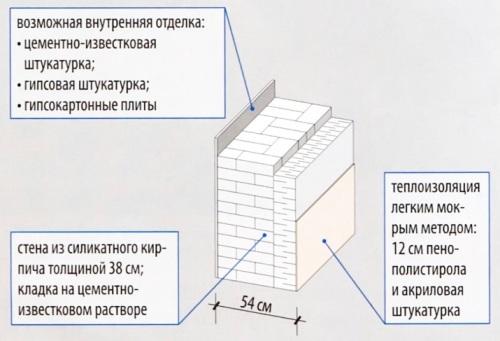

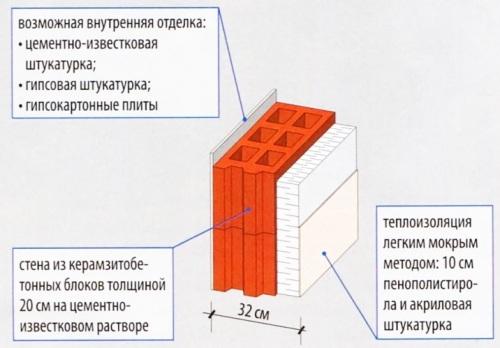

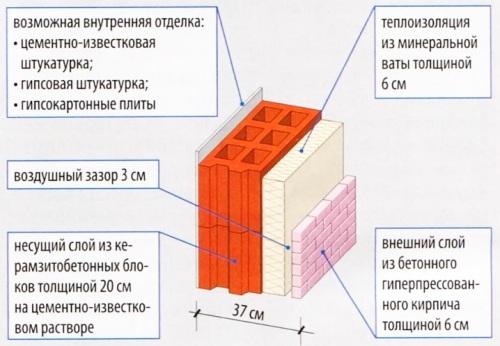

Typical wall designs for permanent residences:

You can read more about the energy efficiency of various building materials in the article. Thermal characteristics of wall materials.

Choosing a building material

Wooden house usually chosen by people who prioritize the environmental friendliness of the building. In such a house, it is most pleasant to take a break from a hard working week, get enough sleep, get psychological relaxation. wooden walls maintain a very comfortable atmosphere for a person - the optimal level of humidity and air exchange. Stone house, first of all, a practical choice. Minimal operating costs, low heat loss and long service life are the factors that make you think about building such a home. Combined house- a house that allows you to combine the practicality of a stone house with the light atmosphere of a wooden one. The stone first floor provides space for practical solutions and design experiments, and in the bedrooms of the wooden second floor, sleep will be strong and pleasant. General comparative characteristics of materials are summarized in two tables. The tables contain general information, and not technical coefficients and parameters, which, in case of interest, are not difficult to find. Table 1.|

Material In order to achieve a sustainable project, the right choice of materials for use must be considered. Here's an overview of the main materials to know before choosing your patio material, depending on the type of home, space, and style of your property. Here are some patios you can use. Because of its durability, fiberglass spikes are a smart choice as a patio cover. Moreover, it is available in multiple colors. Refer to our article to learn about the maintenance, installation, advantages and disadvantages of a fiberglass balcony. |

+ |

- |

|

Light weight (600 - 900 kg / m3) allows the use of a light, shallow foundation. The material is environmentally friendly, acts as a natural filter in the room. The ability to leave the inner and outer surface of the walls without additional finishing. Possibility of year-round construction, wide architectural possibilities, attractive appearance. Price. Wood is very often used as a terrace cover. This material is perfectly compatible with all living styles, so check out our article to see if a wood patio is right for you: Composite wood is becoming more and more common. Before installing the patio. Create an accurate plan and set a budget. Preserve the architecture of your home and respect the environment. outside. Consider the upkeep of your patio and the time available to you before purchasing materials. At all times, ask about municipal bylaws and permits if needed. |

Fire hazard, biological attack, wood shrinkage, cracking, lower durability compared to stone houses, lower heat transfer resistance of the wall. |

|

|

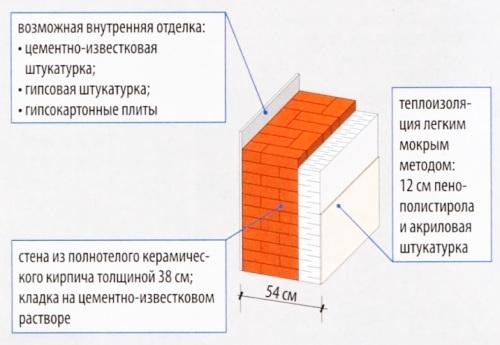

Warm ceramics |

High degree of protection against fire, low exposure to weathering, no biological attack, high structural strength, durability, good vapor permeability. Consider accessories on your balconyPrioritize sustainable construction by choosing suitable materials. Be honest about your skills, they will likely motivate your choice of materials. Several rooms and accessories become a must for building a terrace like this. Lattice; Ramps; bars; Pole caps; Door; beams; beams; Benches; Table; Chairs; Pillows; Light; B-B-Q. Make a detailed list of everything you need to remember, but most importantly, to fit and respect your budget. Think "restore" to personalize your environment. A terrace is reached, completely made of reclaimed wood of the palette. You can also make a factory wall with the same materials. Use Mason pots to create original candle holders, an old chair as a planter and why not use it as a swing. In short, let your creativity go. |

The desirability of using foundations poured to the depth of soil freezing. Internal wall decoration is required, restrictions on the construction of walls in the winter. The complexity of attaching heavy hinged structures to hollow walls. Sufficiently large wall thickness - 51cm (without insulation). High price. |

|

Monolithic houses The life of a terrace usually depends on two main criteria: the choice of materials and an installation that complies with the rules of engineering. Sustainable construction and all environmental factors must be considered when choosing materials for the construction of your terrace. Do you feel a little in your home? Would you like to extend your stay or just have an extra bedroom or two? One of possible solutions is an extension of your living space by building a house. The principle is to build a new building attached to your main house. This annex can be built on one or two floors according to your needs and desires. And it is important to know that when developing applications, several methods are possible. |

Short construction time. Savings in the construction of foundations. Savings on the cost of wall materials. High thermal performance of the walls. App Trend: Building a Wooden Extension for Your HomeAlready in the choice of building materials you are offered a wide arsenal of possibilities. For several years, wood has attracted itself in all house installations and in all constructions. What's more, more and more households are choosing to forego building a wooden or wooden framed house. What to build a house from?From now on, it is quite possible to choose a wooden extension design. This noble material offers many advantages for home applications. Therefore, this type of construction does not require such important reasons as for applications in classical materials. Depending on the type of wood chosen, its resistance to decay and fungi will be greater or less. Most of the wood parts of your application can be made in a workshop. Wood expansion provides real thermal performance as well as sound insulation. Thanks to this noble material, it is possible to realize many types of applications, small or large, in all architectural styles.

|

Not a natural eco-friendly material. Wall decoration required. For plaster, special expensive materials are used - "wet plaster". |

| gas silicate blocks (gas blocks) |

Good vapor permeability, high heat capacity. Does not emit any harmful substances into the atmosphere. Good frost resistance and durability. |

Requires more complex foundations compared to monolithic houses. Difficulty of attaching heavy hinged structures to fragile walls made of gas blocks. Inability to work in winter. More traditional structural steel structureWe are talking in particular about Afzelia, beech, teak, Ipa tree and many other species. Depending on how the wood is processed, it can change slightly over time. Does the wooden frame tempt you? You can choose a more traditional structure for your extension, such as metal beams. This more classic design is sure to take longer to set up. But this, in particular, makes it possible to achieve excellent modern achievements. Other siding available for your applicationNo matter what base structure has been chosen to build your application, it can receive a variety of sidings, each bringing an aesthetic and specific final rendering. Yet again, different types woods with different shades and sizes offer a very specific and warm aesthetics. Double Brick wall: it is formed in most cases from bricks on the outside and blocked inside. From an aesthetic point of view, choosing this material gives a more modern and sophisticated look to your application. Classified house extension: attention, all implementations are not allowed

|

Table 2.

| materials | Thermal conductivity | Reliability | Environmental friendliness | Exploitation | Foundation cost | Fire safety | Vapor-air-permeability |

| Beam and log | * | ** | *** | * | *** | * | *** |

| gas silicate block | ** | ** | ** | *** | ** | *** | ** |

| Foam block | * | * | ** | ** | ** | *** | ** |

| Monolith in fixed formwork | *** | *** | ** | *** | ** | ** | * |

| Warm ceramics (porous brick) | ** | ** | *** | *** | * | *** | ** |

Some additions.

Types of wall materials for wall construction

Therefore, it is important to go through the architect who will be requesting this permission. But also to advise you on the construction, design and material selection of your application. Also note that if you want to bring an extension to a dwelling or to a listed building, none of this is possible. Indeed, an application to a building of this type must respect certain rules. And here the architect can advise you! Thus, the style of the added building addition must be identical to the base building.

To maintain normal heat and humidity conditions in a brick house, it must be constantly heated. If the house has not been used in winter, then in the spring it will have to be thoroughly heated before it warms up and the rooms become dry. A house made of wood or a monolithic house built using fixed formwork technology does not require heating during the winter.

Ask for full support for the construction of your application!

Feel free to ask our project coordinators for your expansion project. We will accompany you throughout the work to give you advice and coordinate as much work as possible! Academy management no longer has magic the first time around. Being the Lord of the Dark Brotherhood is killing you with boredom. The Guild of Truth affair has stolen too much of your time.

Skyrim is cold, life is hard and you're wasting some time for no good, and just like you need to wear the Amulet of Mary to marry a human, now all you have to do is go to the Riften Orphanage and pick two random rabbits for your family.

The construction of a heavy foundation and thick brick walls is significantly more expensive compared to building a wooden cottage or building a monolithic house.

In a wooden house more intensive exchange and purification of air. Up to 30% of the air per day can change through a log or timber indoors, and the unique properties of these materials allow in dry weather to release accumulated moisture, and in wet weather, on the contrary, to absorb its excess from the living space. That is why wooden houses are distinguished by a special microclimate and high level comfort. Wood is a very living material. Even after the log house, it continues to breathe, radiate heat energy, exude the aroma of resin. Wooden houses give people bioenergetic nourishment, heal them, have a positive effect on the human nervous system.

Construction of a monolithic house with fixed formwork gives creative scope to the most daring architectural ideas. In this material, you can bring to life any architectural forms - from a warm garage for an iron pet, to the floating lines of a small country residence. And the heating of the building can be proud of the neighbors - it is so economical.

A house made of warm ceramics is a combination of durability, reliability and environmental friendliness. The walls of such a house will stand for more than one hundred years, paying off their rather high cost. A house made of such blocks does not need additional insulation (with a wall thickness of 51 cm). The use of natural clay as a basis for ceramic blocks guarantees the absence of any chemical impurities in the air. Such a house is a long-term investment in which more than one generation of descendants will live.

So decide!! If your choice is in favor of cozy wooden house or you are attracted by the reliability and durability of stone - contact our construction company, we will help you choose a project from the catalog, or we will develop a new one for your needs.

WOODEN HOUSING

Which tree is best?

Many developers are faced with the question of what kind of wood to build a house from. During the construction of a wooden house from time immemorial, preference was given to coniferous trees - larch, pine and spruce. Not without reason there was a saying among the people: “The hut of the spruce, but the heart is great!”

The best-known material for timber construction is pine. It has a hard, resin-impregnated core and a looser

upper part. Of all conifers, pine is most often used in construction. It is distinguished by the greatest straightness of the trunk, the minimum number of knots and good technical properties. Pine has a high resistance to decay, but often (especially in July-August) with high humidity it tends to "turn blue". Blue in itself does not change the physical and mechanical properties of wood, but spoils the appearance. Pine is the main material for the construction of wooden houses, both in our country and in Europe (in particular, in Finland).

No less popular building material is spruce. The physical characteristics of these rocks are very close. Spruce has a stronger outer skin but a softer core. When dry, spruce wood is as strong as pine wood. Spruce is more prone to decay, but turns blue much less. On the world market, spruce is valued higher than pine.

Another building material (almost perfect) is larch, which has a unique, only inherent pattern. Larch is stronger, denser and practically unaffected by moisture, but it is more difficult to process than pine and splits easily. Therefore, larch is ideal as a wall material, but is not used for structural material (beams, valleys, rafters, puffs, etc.). However, this material is relatively expensive and not available to everyone.

What are the walls made of?

Our construction company offers a wide range of building materials for your home or bath. Let's look at their main types.

Technological material that requires a minimum of manual labor when  building a house, as the house is assembled according to the principle of a constructor. All necessary operations with rounded logs are performed at the place of production, in particular, the choice of mounting cups and landing channel in rounded logs.

building a house, as the house is assembled according to the principle of a constructor. All necessary operations with rounded logs are performed at the place of production, in particular, the choice of mounting cups and landing channel in rounded logs.

The advantage of a rounded log is its even, rounded shape, which makes it possible to achieve a dense connection of logs. The diameter of rounded logs ranges from 160 to 320 mm. And due to the same diameter and high quality surface treatment rounded logs do not require wall finishing.

Advantages of building houses and baths from logs:

Accuracy in the production of rounded logs and their marking speeds up the assembly of buildings and reduces construction costs;

The beautiful appearance of rounded logs due to the high quality and cleanliness of the surface treatment makes it possible to do without additional wall decoration inside and outside;

The tightness of the crown and corner joints of the logs is ensured by the technological accuracy of the groove and "cups";

Aesthetic appeal of buildings built using logs.

2. Hand-hewn logs up to 40 cm in diameter

For manual cutting, environmentally friendly, high-quality wood (spruce, pine, larch) is used, not infected with woodworm and fungus, with a moisture content of 45-60%. It is quite easy to process and deforms less when  natural drying in assembled form. Logs undergo manual processing: removal of bark, proteza, selection of cups and grooves, processing with a planer. With this treatment, the upper solid protective layer of the log (“sapwood”) is preserved. Hand-hewn logs are less deformed during the aging process. Corner joints of logs between themselves are made in a "bowl" or in a "paw", the crowns are fastened with wooden spikes (nagel) after 1000 - 1500 mm, all logs are treated with an antiseptic. Such houses are warmer than those assembled from rounded logs, their walls are less prone to cracking. And with high-quality processing of logs, the appearance of such houses is not much inferior to houses made of logs.

natural drying in assembled form. Logs undergo manual processing: removal of bark, proteza, selection of cups and grooves, processing with a planer. With this treatment, the upper solid protective layer of the log (“sapwood”) is preserved. Hand-hewn logs are less deformed during the aging process. Corner joints of logs between themselves are made in a "bowl" or in a "paw", the crowns are fastened with wooden spikes (nagel) after 1000 - 1500 mm, all logs are treated with an antiseptic. Such houses are warmer than those assembled from rounded logs, their walls are less prone to cracking. And with high-quality processing of logs, the appearance of such houses is not much inferior to houses made of logs.

If you like the old Russian or Finnish style of houses - this is your stuff!

A house made of profiled timber is an island of comfort and coziness in the world of concrete jungle. A wooden house will delight its owner with a very comfortable indoor atmosphere - after all wood is an excellent natural conditioner ,

maintaining air exchange and humidity at a very comfortable level for a person.

A house made of profiled timber is an island of comfort and coziness in the world of concrete jungle. A wooden house will delight its owner with a very comfortable indoor atmosphere - after all wood is an excellent natural conditioner ,

maintaining air exchange and humidity at a very comfortable level for a person.

In the manufacture of profiled timber, a high purity of the treated surface is achieved, so the wood becomes almost polished, which makes it possible not to use additional materials for the interior decoration of a wooden house, and therefore avoid unnecessary costs. Unlike log walls, the walls in a cottage made of profiled timber are even,  o facilitates possible finishing, arrangement of furniture, use of wall cabinets.

o facilitates possible finishing, arrangement of furniture, use of wall cabinets.

Currently, many prefer this particular material. The ratio "price-quality" is optimal here. Cottages made of profiled timber are very modern, look great, keep temperature fluctuations well, which is very important for the regions of central Russia.

The construction of houses and cottages from profiled timber is a technological process that includes the processing of material on a machine tool, the preparation of a “cup” with a double lock. Pre-assembly at home in the workshop is possible, which ensures particularly high assembly accuracy. The final assembly includes the erection of a log house at the construction site, drilling and fixing the timber with dowels.

During the construction of cottages and country houses from profiled timber, our company uses material manufactured by one of the company's departments.

4. Ordinary sawn (unplaned) timber

This is the cheapest building material made of wood. The sawn timber used for the construction of the well of a wooden house is made of an equilateral section (150x150mm, 200x200mm), or a versatile section (from 150x100 mm). In construction, either simply sawn timber is used, or planed (on one or two sides).  Basically, an ordinary bar with a section of 150x150, 200x150, 200x200 mm is used for the construction of country houses (optimal ratio: price / quality), and a larger one - for the construction of cottages with subsequent insulation and finishing with other facing materials.

Basically, an ordinary bar with a section of 150x150, 200x150, 200x200 mm is used for the construction of country houses (optimal ratio: price / quality), and a larger one - for the construction of cottages with subsequent insulation and finishing with other facing materials.

However, we must not forget that a simple bar does not have a thermal lock. Because of this, it is difficult to insulate it, because. the blowing coefficient will be several times higher than that of a wall made of a properly made log or profiled beam. In any case, after 1 - 1.5 years (after the shrinkage of the log house), it is necessary to carefully caulk the seams between the beams and sheathe the walls with finishing materials both inside and outside (lining, saiting, etc.). All these activities absorb the savings obtained by purchasing the timber itself. The benefit here is one thing - such a house can be built (and, therefore, invested in it) in stages, with a stretch over time.

Naturally, with any option for building a wooden house, antiseptic treatment of the walls with special compounds and paints should be implied, protecting the wood from turning blue, putrefactive disease, mold and woodworm beetles.

TECHNOLOGIES OF THE XXI CENTURY: Monolithic houses in fixed formwork

AT modern world, where prices for  building materials, as well as electricity, gas and fuel are growing rapidly, the question of the cost-effectiveness of building cottages is quite seriously raised, and in the process of operation - savings on heating and air conditioning houses.

building materials, as well as electricity, gas and fuel are growing rapidly, the question of the cost-effectiveness of building cottages is quite seriously raised, and in the process of operation - savings on heating and air conditioning houses.

For this reason, we propose technology of monolithic housing construction "Izodom" (using non-removable formwork made of expanded polystyrene). This technology for thermal protection, sound insulation, comfort, simplicity and speed of construction, as well as  durability refers to the advanced technologies in the field of construction and is designed for the rapid construction of warm, reliable and inexpensive homes.

durability refers to the advanced technologies in the field of construction and is designed for the rapid construction of warm, reliable and inexpensive homes.

This technology has been tested for many years in the USA, Canada and Western Europe, confirming the cost-effectiveness and durability of this system, and in last years begins to be popular in Russia. The sphere of application of Izodom technology is the construction of cottages, rural houses and summer cottages; construction of shops, cafes; multi-storey residential buildings; warm individual pools, garages and much more.

What gives developers the Izodom technology (monolithic houses)?

Reduced construction time. When using traditional materials (such as brick), building a house stretches for a long time. If you build using the Izodom technology, the same wall area is built several times faster.

savings when constructing foundations, since Izodom walls create a much lower specific load on the foundation. For such a house, it is recommended to install a shallow foundation.

Savings on the cost of wall materials. Price square meter Izodom walls are significantly lower than the cost of a brick wall, similar in terms of heat saving.

Benefit from obtaining additional usable area, since the thickness of the walls of "IZODOM" is much less than the thickness of walls made of other building materials, similar in terms of heat-saving capacity.

High thermal performance of walls- this is a way to avoid high costs for the purchase of expensive heating equipment, transportation of fuel, time and labor costs for its operation. The cost of heating the IZODOM building will be 3-4 times less compared to a brick building.

How cottages are built from monolithic concrete.

The modules of the Izodom system are hollow polystyrene blocks with a density of 25-27 kg/m3, which are joined together like parts of a children's designer. Fixed formwork modules have cavities that are reinforced and filled with concrete during the construction process, and a special  the design of the locks allows you to quickly and accurately connect the blocks. Thus, a monolithic wall is constructed, framed on the inside and outside with a heat and sound insulating shell of expanded polystyrene. Thanks to this wall construction, houses built using fixed formwork are strong, light and very warm. The thickness of the wall is selected depending on

the design of the locks allows you to quickly and accurately connect the blocks. Thus, a monolithic wall is constructed, framed on the inside and outside with a heat and sound insulating shell of expanded polystyrene. Thanks to this wall construction, houses built using fixed formwork are strong, light and very warm. The thickness of the wall is selected depending on  the purpose of the building, as well as the temperature parameters of the construction region.

the purpose of the building, as well as the temperature parameters of the construction region.

The internal partitions of the house can be made from the same blocks, as well as from any other traditional materials. During the construction of buildings, you can use any type of floors - monolithic floors, concrete slabs or classic wooden floor structures.

For exterior finish walls can be plaster, siding, facing brick or stone. Interior decoration can  carried out using plaster or plasterboard. The undoubted advantage of a house built using this technology is that the walls, both internal and external, have a very even surface, therefore, an economical thin layer of plaster is needed to finish the walls. In addition, it is very easy to lay electrical wiring in such walls.

carried out using plaster or plasterboard. The undoubted advantage of a house built using this technology is that the walls, both internal and external, have a very even surface, therefore, an economical thin layer of plaster is needed to finish the walls. In addition, it is very easy to lay electrical wiring in such walls.

Expanded polystyrene is environmentally friendly (97% air and 3%  material) and is even used for food packaging. It does not contain substances that feed microorganisms, i.e. not subject to the destructive effects of rodents, mold and bacteria. In addition, it does not burn if there is no prolonged exposure to the flame (more than 2.5 hours).

material) and is even used for food packaging. It does not contain substances that feed microorganisms, i.e. not subject to the destructive effects of rodents, mold and bacteria. In addition, it does not burn if there is no prolonged exposure to the flame (more than 2.5 hours).

Technical parameters of the walls.

Wall thickness - 25, 30 or 35 cm, where 15 cm is concrete, the rest (respectively - 10, 15 or 20 cm) is polystyrene foam.

The weight of walls without finishing is 400 kg/m2.

Concrete consumption - about 125 liters per square meter of wall.

Thermal conductivity coefficient - L0=0.036 W/mK, excluding exterior and interior finishes.

The fire resistance limit of the wall is 2.5 hours.

Vapor permeability - 0.032 mg / (m.ch. Pa).

Water absorption in 24 hours, by volume - 0.1%.

Acoustic isolation - 46 dB.

Fire safety:

The fire hazard class of the load-bearing wall is K0 (the fire spread limit is 0)

The fire resistance limit of the load-bearing wall is at least 155 min.**

* According to the conclusion of the State Unitary Enterprise "NIIMosstroy"

** According to the tests of the center of the Federal State Institution VNIIPO EMERCOM of Russia

Whatever material you choose to build your house - we will be happy to help the future homeowner decide on a project or develop an individual one, discuss materials and finishes, and build STRONG HOUSE according to your wishes, tastes and possibilities.

After the decision to build your own house is made, the question immediately arises: “What to build a house from?”. Although the construction of the walls of the house is only 10% of the total construction, it takes a lot of time to solve it. Later in this article, we will look at 16 design options for the exterior walls of the house. You will only have to choose.

How to build a house?

In the beginning, let's figure out what affects the choice of material? Perhaps the main criteria when choosing building materials will be safety, strength and energy-saving properties. In second place will be the cost of materials, then the speed of construction and who will carry out all the construction work and manage the construction process.

Before starting construction, you need to decide who will build the house. There are only a few options: build on your own, with one experienced contractor, with several contractors under the contractual system.

Let's consider each option in detail:

- Building a house with your own hands. If you want to take part in all construction processes and personally control the progress of construction, then you need to build a house from the maximum simple designs and well-known technologies. So you save on construction work.

- The house will be built by one contractor. This is usually a well-known and experienced construction company that has been operating in the construction market for a long time and has an excellent reputation. She can be entrusted with the construction of a house of any complexity and with any materials. They can use the most modern technologies, and will not puzzle over the complexity of certain works. This is the easiest, but also the most expensive way to build a house.

- Construction of a house with several contractors. In this variant, you will act as a construction inspector and a procurement officer. All work will be carried out separately by hired specialized teams. The main thing is that you have at least a theoretical understanding of construction processes and technologies. You will have to negotiate a lot and look for compromises. This method will be the most difficult and time-consuming.

Let's solve the question of how to properly combine the method of building a house and technology.

First of all, you need to choose a competent and knowledgeable master. A highly skilled bricklayer is able to perform work of any complexity. If, for some reason, the work is entrusted to an inexperienced specialist, then it is useful in this case to know the following rules.

- The laying of a single-layer wall on a thin seam must be carried out with special care and strictly follow the technology, although it does not take much time. And although the blocks used to build the wall, thanks to the available side ridges and grooves, are easily erected, they themselves are very heavy, and most importantly, fragile. For these reasons, they are more difficult to work with.

- Laying a two-layer wall on a standard mortar does not require great skill and experience, but is more time-consuming. The advantages of this procedure are as follows: the heat-insulating layer makes it possible to hide flaws, and minor inaccuracies in the work will make it possible to compensate for a thick layer of mortar. But you should know that all work on the application of elements of the insulation system, including three-layer plaster, should be carried out by an experienced and knowledgeable master.

- What are three-layer walls made of? Firstly, the carrier layer, laid on a conventional mortar, then the heat-insulating layer, and finally, the outer layer, which performs protective and decorative functions. Can build on your own bearing walls, but it is better to leave all the insulation work and the construction of a protective wall to an experienced craftsman.

- Frame walls have their own characteristics. For them great importance has strict adherence to the technology for connecting the wall with a vapor barrier inside and a vapor-emitting membrane under the casing from the outside, which makes it possible for moisture to ventilate from the internal space of the frame.

Remember that absolutely any technology requires a competent approach and thinking through all the stages. Even a small violation or ignoring one detail can lead to a big problem and poor quality results. For example, information about the simple process of building houses with single-layer walls is widely known. But, this process only seems simple, and even minor flaws can lead to serious problems.

A good tool is also very important for successful construction. If you used the services of a team of professional builders, then, of course, the issue of a good tool will not bother you. If you decide to purchase everything you need for construction on your own, then it is worth remembering that in addition to the required tools, you will have to buy non-standard equipment. For example, special containers for applying adhesive compositions. Or, for example, when erecting prefabricated houses from prefabricated panels, the customer needs to take care of a good road for the passage of trucks. This will significantly increase the pace of work.

External walls of the house. main parameters

Before choosing a material for the walls, let's look at the main parameters of the exterior walls of the house, namely: "What are the optimal indicators of thermal insulation of exterior walls?", "Do the walls have to be vapor-permeable?", "What affects the sound insulation of walls?", "How durable and strong Are walls made of different materials?”, “How do water absorption and frost resistance affect the quality of building materials?”, “How does the elements affect walls made of different materials?”.

When building a house, it is necessary to take care of the construction of "warm" walls, which are able to provide the required resistance to heat transfer R. Thanks to this, you can sufficiently save the costs associated with living in the house.

The value of 2.8 m2 K/W is taken as the optimal indicator R. It is this indicator that is established by the construction standards for the first, coldest in temperature, zone of Ukraine. The heat transfer resistance R can be determined by the formula R=α/b, where α is the thermal conductivity and b is the thickness of the wall material.

What is called the coefficient of thermal conductivity α? He named a parameter that characterizes a product or the material itself. Currently, there are wall materials that can provide the desired resistance to heat transfer, while being a single-layer structure. These materials are blocks of cellular concrete, having a thickness of 30 cm or more, as well as large-sized hollow blocks of porous ceramics, with a thickness of 44 cm. amount of solution.

Single-layer walls built from silicate or ceramic brick. Of these types of bricks, multilayer structures are erected, which necessarily include a heater. This role can be played by expanded polystyrene or mineral wool in slabs. In such structures with many layers, the heat transfer resistance is calculated as the sum of the resistances of each individual layer. The required thickness of the insulating material is calculated based on the normative indicator R. In wooden frame walls, the resistance to heat transfer gives a layer of thermal insulation, which is initially included in the design.

Vapor permeability is a positive characteristic of walls, it is also described by such a concept as “a wall that breathes”. The steam that is formed in the process of life will freely go out through the wall structure. But at the same time, do not forget that the house must also have good ventilation to maintain an optimal microclimate.

The materials that allow steam to pass through include porous ceramic blocks, cellular concrete blocks, mineral and gypsum plaster, mineral wool.

Materials that do not allow steam to pass through or have a low vapor permeability coefficient: clinker bricks, tiles, polystyrene foam, water-based paint, acrylic plaster, and of course a vapor barrier film.

In order for a wall to be truly vapor-permeable, all its structural layers must be made of vapor-permeable materials.

Sound insulation of external walls is regulated building codes and depends primarily on the noise level outside the house. If you are building a house in the city center, near a high-speed highway, an industrial enterprise, a workshop, railway, airport, then this characteristic of the walls is extremely important and you need to pay attention to it first of all.

The acoustic properties of the wall are characterized by the sound insulation index Rtran. The higher this figure, the better the wall is protected from noise.

What determines the soundproofing properties of a wall?

- Wall weight. The more massive the wall, the better it will protect the house from extraneous sounds coming from the street. Walls made of bricks and ceramic concrete, weighing more than 330 kg/m2, have excellent soundproofing properties.

- Air voids in the wall structure. But not all voids will equally well protect the house from sound waves. For example, hollow material with rectangular voids that are perpendicular to the length of the wall will best protect the house from strong sounds.

- Insulation. Many mistakenly believe that if the wall is insulated with foam plastic or mineral wool boards, then their sound insulation will increase. This is not so, and can lead to a decrease in sound insulation due to resonance phenomena in the insulation. Mineral wool with a density below 80 kg / m3 is considered a good sound insulator.

- Wall plastering. Both external and internal plasters can improve the soundproofing properties of walls. On average, every 2 cm of plaster increases sound insulation by 2-3 dB. As for dry plaster or drywall, it only works when it fits snugly against the wall. In frame structures, it is necessary to provide soundproof gaskets between the frame and the slabs.

What should be the soundproofing index?

- For a wall without window and door openings, R trans should not be lower than 45 dB for a house in the city center and 25 dB for a country house.

- For a wall with a window in the area of increased noise, R trans is at least 38 dB, under normal conditions, at least 20 dB.

- For windows in walls with less than 50% glazing: Vacation home- 20 dB, in the city center - 35 dB.

![]()

The minimum service life of a new house is 40-50 years. It is for this period that all houses are calculated, regardless of the materials of their construction. What is the actual service life and what it depends on, you will learn in this later.

The service life of any house depends on several factors: first of all, on the quality of materials, compliance with construction technology and operating conditions of an already built house. As practice shows, the house will serve you much longer than I said. Why? No one wants to do major home repairs very often, and therefore even the most uneconomical home owner will do a minimum of work to delay this repair.

The service life of a house depends not only on load-bearing walls, but also on finishing and insulating materials, as well as on engineering. For example, cement-lime plaster should last about 50-60 years.

How many houses from different materials will serve, statistical data.

The leader in terms of service life is a brick house, it will serve you 100 - 150 years. In second place, houses made of light materials (blocks) will reliably stand for 80-100 years. But frame wooden houses will last only 25-40 years.

These are average figures and you need to remember that the proper operation of the house is the key to its long service life. So, for example, with skillful exploitation wooden house will stand for more than 100 years, at a time when a sloppy attitude to brick house make it uninhabitable in 30-40 years.

Most affected by precipitation Decoration Materials facade. Therefore, they must be as frost-resistant as possible and have minimal water absorption. For example, for facade materials, the frost resistance mark should be from 25. If this is not followed, then after the first winter it will be necessary to repair the facade, as cracks will appear on it.

The best finishing material is silicate and clinker bricks, as well as acrylic plaster. But materials with high water absorption require special storage conditions, and with an illiterate robot, problems may arise with them.

For example, aerated concrete is a material that has a high degree of water absorption, but at the same time it is a very popular building material. Everything is very simple here. After laying such material, it must be protected, for example, with plaster. The main thing is not to leave for many years under the influence of precipitation.

What can significantly affect the durability of building structures? That's right, natural disasters in the form of fires, floods, hurricanes. Let's take a look at the impact of fire, water and wind on residential buildings and what materials are best used in building a house.

Fire

Fire can bring the greatest damage to a home. After a fire, restoring a building will be very expensive, and sometimes not even profitable. The main thing to remember here is that human life is more important than any home.

Walls made of ceramic materials, silicate bricks, gas and expanded clay concrete are best resisted by fire. At that time, insulating materials made of expanded polystyrene and polyurethane, although they do not support the spread of fire, can still turn into a fiery rain of burning droplets and release toxic combustion products harmful to humans. Therefore, in this case, it is better to use a non-combustible insulation, for example, mineral wool.

As for wooden houses, these are fire-hazardous buildings, even if all structural elements are impregnated with fire-protective substances and are finished with non-combustible materials. All these measures only increase the evacuation time. Wooden houses are almost completely destroyed by fire.

Wind

The least resistant to strong winds are wooden frame houses. In a hurricane with a wind speed of more than 180 km / h, they are destroyed almost completely. While brick houses withstand winds up to 400 km/h.

You can find out the maximum wind speed in your area from normative documents. And already from this choose the material for building a house.

Water

The worst thing about flooding is that the level of flooding cannot be accurately predicted.

Brick walls will be the most resistant to water. Even if they get wet, their strength will not decrease from this. It is enough to dry such a house and everything is suitable for further operation. If the house has been insulated and the insulation has absorbed moisture, then it must be replaced with a new one.

The best option for flooded areas would be a house with single-layer walls, for example, made of cellular concrete, which dries very well and quickly.

If it floods a wooden house, then in the future it will be overhaul. It is necessary to remove all finishing materials, dry the house and refinish it.

Materials for building a house

And now we come to the most important question: "What to build a house from?". Next, consider the use of the most popular and unpopular building materials for the construction of the outer walls of the house, their pros and cons.

Today, ordinary ceramic bricks, which are produced by firing clay, are used very rarely due to poor thermal performance. Brick walls are built in two or three layers with effective insulation. This building material is very versatile, as it has a small size (250x120x65 mm) and allows you to build walls of any geometry. At the same time, this is also its disadvantage, since brickwork is very laborious. Today, most often ceramic bricks are used as cladding in a three-layer wall.

There is also hollow brick and stone, which is slightly larger, which means construction will be much faster.

Also, large-format blocks made of porous ceramics are gaining more and more popularity. Such blocks are made by mixing sawdust and clay, and as a result of firing, micropores are formed in the material in in large numbers. Therefore, such blocks have high thermal insulation properties and are used for the construction of single-layer walls.

What are ceramic walls?

Walls made of ceramic materials can be one-, two- and three-layer. Let's talk about how to build such walls?

Single wall. It must necessarily be built from large-format porous blocks. Their thickness is usually 44 cm. They need to be laid on a special glue, which forms a very thin seam, which increases the thermal characteristics of the wall.

Double wall. Such a wall is built from ordinary ceramic bricks or hollow, very rarely from porous narrow blocks. The bearing layer of the wall is 19-38 cm. The wall is laid on a cement-lime or heat-saving mortar. The second layer is a heater, its thickness can be from 5 to 20 cm, it all depends on the construction area and the wall design. The insulation is opened with a thin layer of plaster and the wall is painted.

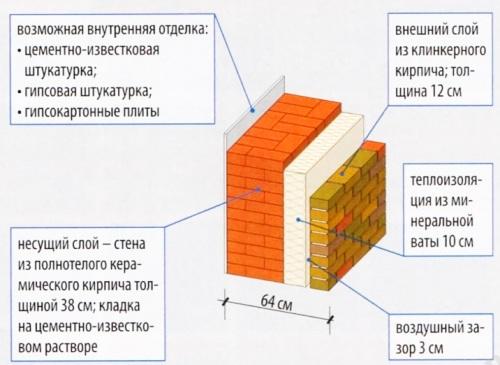

Three layer wall. The bearing layer of the wall is made in the same way as in a two-layer wall. Only during its construction, embedded elements should be laid that will connect the inner and outer layers. Such a wall is usually insulated with mineral wool, 5-15 cm thick. An ordinary brick is used as a facade layer, if the facade is plastered or facing in the future. Be sure to provide a ventilation gap of 3-5 cm between the insulation and the facade layer.

How to get rid of cold bridges in a single-layer wall?

You just need to properly insulate the jumpers above the window and doorways, as well as insulate the crowns. For these purposes, mineral wool or polystyrene 5-10 cm thick is suitable.

You should also pay attention to the construction of the wall itself. Never use cracked or chipped blocks. The thickness of the masonry joints should be minimal. In this case, it is better to entrust the construction of walls to professionals.

Wall units made of ceramic materials

1. Single layer wall plastered with cement-lime plaster 1.5-2 cm.

2. A single-layer wall with heat-saving plaster 3-5 cm thick, which is additionally covered with a thin layer of mineral plaster. This design of the wall will hide all the irregularities and defects of the masonry, as well as increase the coefficient R to 3.1 m2*K/W. More complex in execution than the previous one due to two layers of plaster.

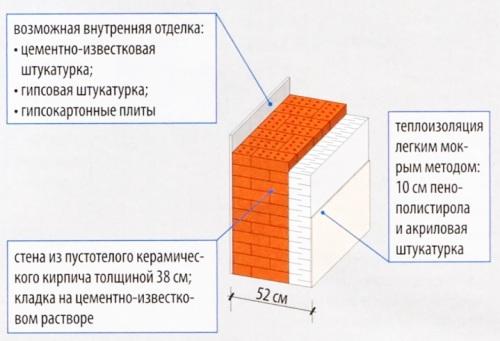

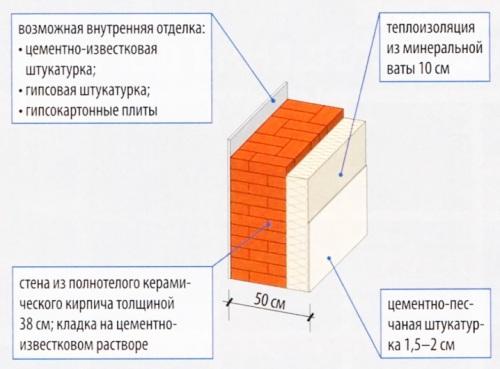

3. A two-layer wall made of solid brick with foam insulation 12 cm thick. The index of such a wall is R = 2.8 m2 * K / W.

4. Two-layer wall with hollow bricks and foam insulation 10 cm. Wall index R = 2.8 m2 * K / W.

5. Two-layer wall with mineral wool insulation 10 cm and plastered with cement-sand plaster up to 2 cm. R value = 2.8 m2*K/W.

6. The three-layer wall is insulated with 10 cm mineral wool and lined with clinker bricks. R value = 2.8 m2*K/W.

First, let's figure out what cellular concrete is and what components it consists of. For the production of lightweight concrete, sand or ash is used, cement and lime are used as a binder, and aluminum paste or powder is used as a baking powder.

The color of concrete blocks depends on whether sand or ash is used as the main component. The sand gives the blocks a pure white color, and the ash gray.

Blocks from cellular concrete are subdivided on grades from D300 to D1200. The higher the grade, the denser the material, and, consequently, its strength is higher, but at the same time it has more weight and greater thermal conductivity.

Blocks are made of rectangular oblong shape and have a smooth surface. For ease of installation, some manufacturers provide a profile structure, which greatly facilitates their installation and transfer by hand.

From cellular concrete, one-, two- and three-layer walls can be erected. The most common are the first two options. Three-layer walls are very rare in private construction. For external walls, blocks of grade not lower than D500 should be used.

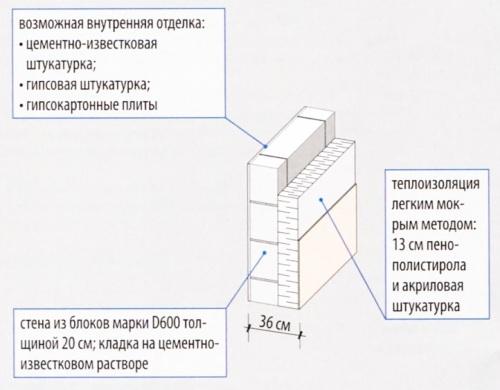

Single layer wall. Such a wall has a thickness of 30 cm to 48 cm. Walls are laid from blocks of the D300, D400, D500 brand with special glue with a joint thickness of 1 to 3 mm. Of course, you can also put blocks on a heat-saving mortar with a thickness of 10 - 15 mm.

double layer wall consists of two layers of carrier and a layer of insulation. The bearing layer is made of concrete blocks of the D600-D700 brand and has a thickness of 20 cm to 40 cm.

three layer wall it is used quite rarely, it consists of a carrier layer of a block, a heater and a finishing material.

The construction of walls made of gas and foam blocks. Knots

2. Single-layer wall with heat-saving plaster. Such a design will allow you to hide minor flaws in the masonry of the walls and, of course, make the wall warmer.

Until recently, a popular building material, such as sand-lime brick today, is losing ground and is being used less and less. silicate brick made from sand (ash, slag), lime and water. He usually white color but can also be dyed any color. Has the correct rectangular shape and ugly surfaces, however, one of the faces may have a textured surface. A brick can be either solid or hollow.

Basically, this material is used for wall cladding, as it does not need further finishing.

In Europe, large-sized silicate blocks are very popular, from which walls are built much faster.

Such a brick is not suitable for the construction of single-layer walls, because it has a high thermal conductivity. It is possible to build two-layer walls with a bearing layer of 25-38 cm and a heater of 12-15 cm. It is also possible to build a three-layer wall in the same way as a two-layer wall with the addition of a finishing layer 12 cm or 6.5 cm thick.

Silicate brick wall construction

Expanded clay blocks are made from concrete and expanded clay. Thanks to expanded clay, the material acquires improved thermal insulation properties, since expanded clay has a porous structure. Expanded clay blocks are gray in color, but can also be painted in dark red.

Due to the presence of tongue-and-groove connections in the blocks, significant savings on mortar are achieved and the number of cold bridges is reduced.

Walls made of expanded clay concrete can be single-layer, two-layer and three-layer. Let's take a closer look at the design of each of them.

A single-layer wall of expanded clay concrete blocks of domestic production is not being erected. But in Europe, blocks with a thickness of 36 cm are used. They are laid on a heat-saving solution with reinforcement every 1.5 meters.

A two-layer wall is a more common option. The carrier layer in this case is 20 or 24 cm and is equal to the width of the block. The second layer is a heater, which can be from 5 to 15 cm thick, it all depends on the requirements for thermal insulation of walls in a particular region.

A three-layer wall will be similar in design to a two-layer wall, with the exception of the facing layer, which is made of facing brick 6.5 or 12 cm thick.

Concrete wall construction

Let's look at an example of expanded clay concrete walls. How to properly build them.

1. Double-layer wall finished with styrofoam with plastering. The heat transfer coefficient of such a wall is R = 2.8 m2 * K / W.

2. A three-layer wall with mineral wool insulation and a hyper-pressed brick finish with an R value of 2.8 m2*K/W.

The frame of a wooden house is built from pine wood. Wooden elements should not have knots and cracks, they should be planed on four sides and dried in a chamber. The moisture content of the tree should not exceed 18%.

What should be the wall of a frame house?

The design of the wall in a frame house should be as follows (when viewed from inside the house):

- interior decoration, gypsum boards can be used;

- vapor barrier that prevents steam from entering the wall structure from the house;

- thermal insulation layer. Mineral wool, 10-20 cm thick, is used as thermal insulation. The use of foam for insulation frame house undesirable;

- external wall cladding made of chipboard. Plates give the frame a certain stiffness;

- windproof membrane that will protect the walls of the house from blowing;

- exterior finish. Most often, such houses are sheathed with siding or wooden clapboard, but they can also be lined with clinker bricks.

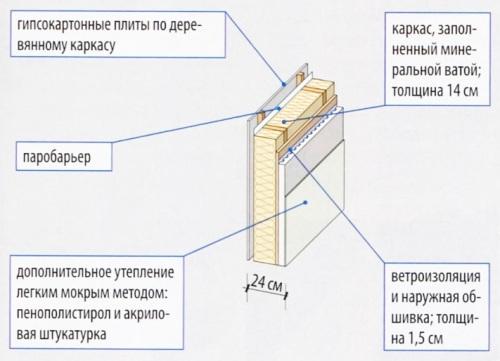

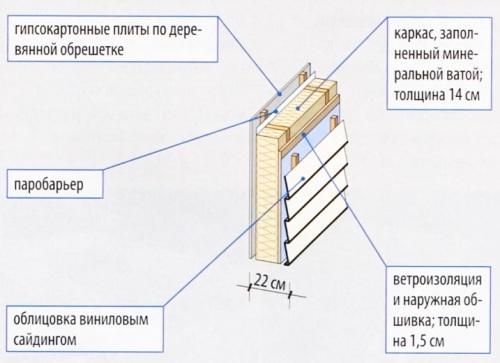

Wall nodes in a wooden frame house

1. Frame wall with stucco facade finishing. R value = 4.0 m2*K/W.

2. Frame wall sheathed with siding. R value = 4.0 m2*K/W.

What else can you build a house from? Alternative technologies in construction

In addition to the above-considered building materials of concrete and wood bricks, other materials and technologies are provided on the construction market, which can reduce financial and labor costs for building a house, while increasing the heat-saving properties of the wall structure.

Among the alternative construction methods, four main technologies can be distinguished: fixed formwork, adjustable modular formwork, 3D panel construction, steel frame. Let's talk about each of them in more detail.

Fixed formwork

The principle of fixed formwork is that monolithic reinforced concrete performs the supporting functions, and slabs, panels or blocks from light materials act as formwork. The formwork is not removed after the walls have hardened, but performs heat-insulating functions.

The walls are built in the following order:

- formwork is exposed in accordance with the project. Its elements are connected using special fasteners;

- reinforcement is laid in the formed voids;

- concrete is poured.

In total, there are several varieties of fixed formwork: "thermal house", wood-cement blocks, wood-cement boards.

What is a "thermo"? This is a fixed formwork made of hollow polystyrene foam blocks. The thermoblock is a structure of two vertical walls 50 mm thick, which are interconnected by jumpers. They can be both made of polystyrene foam and plastic. Plastic jumpers can be removable and non-removable, as well as with adjustable length. The distance between the panels is 15 cm, and the dimensions themselves are 1000x250x250 mm.

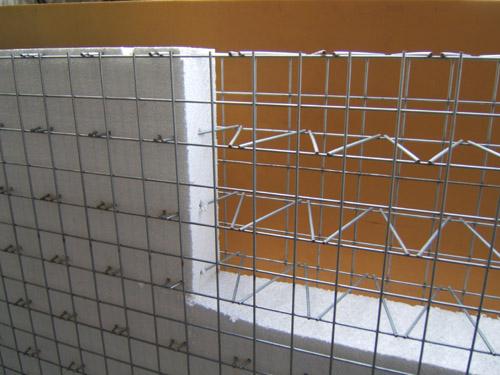

As a formwork made of expanded polystyrene, there can be not only blocks, but also large-format panels made of high-density expanded polystyrene. Such plates are interconnected using a spatial reinforcing cage. The plates are fastened to the frame with the help of nuts-umbrellas made of high-pressure polyethylene. The dimensions of such plates are 3000x1000 mm.

In addition to polystyrene formwork, wood-cement blocks and slabs are widely used. They are made from coniferous wood chips (80-90%) treated with mineral additives and portlant cement is used as a binder.

These blocks can be used to build one-story houses and buildings up to 9 floors. The size of the blocks is as follows: length - 500 mm, height - 250 mm, and the thickness can be 150, 220, 300 and 375 mm, depending on the purpose of the walls. In addition, the blocks are also divided into normal, universal, additional in-line, end and corner. Additional in-line blocks are used to comply with the bonding of the rows of walls. The weight of the block is from 9 to 14 kg. For the construction of 1 m2 of wall, only 8 blocks and 300 g of reinforcement are needed.

This type of formwork consists of two wood-cement boards, which are interconnected by wire ties. The space between them is filled with concrete.

There are several types of plates:

- single-layer - have a thickness of 25, 30 and 50 mm. They are also common and with increased strength and heat-insulating characteristics, they are used both for the construction of external and internal walls;

- two-layer plates have a thickness of 75 - 235 mm. Such a plate consists of a conventional 35 mm plate with a layer of expanded polystyrene glued to it. This type of slab is used for the construction of external walls.

In addition to walls, such plates are suitable for the manufacture of columns, lintels, slopes, floor boxes and other elements.

Plates can be easily increased in height thanks to a welded wire tie, which allows you to build not only one-story houses, but also multi-story ones.

Adjustable formwork TISE is a technology of individual construction and ecology. Thanks to this technology, it is possible to form hollow blocks from a cement-sand mixture directly on the wall without using masonry mortar and with the minimum amount water.

Blocks are made using a special metal mold that does not have a bottom and two void formers. There are several types of modules: TISE-2M 51x15x25 cm in size and TISE-3M 51x15x38 cm in size. After installing the walls, they must be additionally insulated.

A 3D panel is a wall element that consists of a core with expanded polystyrene with a density of 15 kg/m3 and a reinforcing mesh is attached on both sides. The grids are interconnected by diagonal rods made of galvanized steel. The rods pass through the expanded polystyrene and thus form a rigid structure.

The size of the panels can be 3 and 6 meters, and the width is 1.2 m and the thickness is 12 cm for external walls, 10 cm for internal load-bearing walls and 5 cm for partitions. The gap between the mesh and the expanded polystyrene is 19 mm.

The strength of the wall is provided by concrete, which is applied on both sides of the wall structure. concrete mix applied in layers under compressed air pressure.

The steel frame of the house is made from a special thermal profile, which is insulated with cellulose insulation. What is a thermal profile? This is a steel perforated profile, the holes in which are made in such a way that warm air cannot pass through the metal in a straight line. Therefore, the heat transfer of such a wall will be equal to a wall with a wooden frame.

After assembling the frame, a windproof mesh is attached from the outside with a horizontal profile, which will serve as the basis for attaching the ventilated facade. FROM inside cellulose insulation is applied to the wall.

Using this technology, you can build 1-3 storey houses.

I hope we were able to answer the question of what to build your dream home in full. You just have to choose the material!