The construction of any house begins with the choice of the type of foundation that is most suitable in order to provide the future structure with a reliable foundation. Large cottages and houses with massive walls need a monolithic strip foundation buried in the ground around the entire perimeter of the house by at least two meters.

In contact with

The cost of building such a foundation is very high and amounts to almost a third of the cost of the house itself. But for wooden and frame houses, in which the presence of a large basement is not expected, a more rational option would be a columnar-grillage foundation. Its cost is much cheaper, and if the technology is followed at all stages of construction, it will ensure uniform settlement of the entire structure of the house.

Types of columnar foundations

Before starting to build the foundation, it is necessary to carry out all the required geological surveys, determine the type of soil on the surface and at a depth of up to 2 meters, the presence ground water, freezing depth. Using the results obtained, you can choose the type of columnar foundation.

On heaving soils, it is recommended to use reinforced concrete blocks interconnected with reinforcement as supports. In the event that the soil is not very heaving, reinforced blocks can be used. And if the soil is not prone to swelling, then it is possible to use free concrete supports.

Depending on the level of deepening, columnar foundations are divided into the following types:

- unburied;

- shallow;

- heavily recessed.

The supports that form the basis of the foundation can be made of:

- concrete;

- tree;

- bricks;

- asbestos-cement pipes;

- screw piles.

The choice of the type of supports should be made based on calculations of the future load of the house, its size, the approximate number of people who will live in it and the type of soil. The most common type of supports are concrete pillars reinforced with reinforcement.

Preparatory stage

Before starting the construction of the foundation, it is necessary prepare the site. Loose bulk soil must be properly compacted with a rammer or dig a small foundation pit. In the event that the soil is characterized by subsidence, it is necessary to lay the foundation below the freezing depth by 30-40 centimeters.

It is good if the construction site has a slight slope that provides a runoff of rainwater and melted snow. The layer of the vegetative layer of the soil should first be removed to a depth of about 20 centimeters.

The foundation supports must certainly be located at the corners of the future building, at the intersection of the walls and under the main load-bearing elements of the entire structure. Even at the marking stage, all work must be carried out in accordance with the plan of the future home, since mistakes can lead to serious consequences.

Marking begins with the inner contour, hammering the first peg in place of the future corner of the house. Then, using the construction triangle, the parameters of the outer sides of the foundation are determined. Their dimensions are equal to the lengths of the longitudinal and transverse walls. At the intersection of the axes, 2 and 3 pegs are hammered. And after that, the following corners of the house are determined in the same way.

At the end of the installation of the markup, it is necessary to check its correctness using a goniometer. You should also measure the length of the walls, they must necessarily match the parameters specified in the project of the house.

Device

![]() The next step in the construction of the foundation will be earthworks. It is necessary to dig a hole slightly larger than the size of the foundation. Then install the formwork and reinforcement with a thickness of 10-14 mm. Reinforcement bars must be fastened together with reinforcement 6 mm thick and must come out of the foundation to the surface. This is necessary for their subsequent binding to the grillage.

The next step in the construction of the foundation will be earthworks. It is necessary to dig a hole slightly larger than the size of the foundation. Then install the formwork and reinforcement with a thickness of 10-14 mm. Reinforcement bars must be fastened together with reinforcement 6 mm thick and must come out of the foundation to the surface. This is necessary for their subsequent binding to the grillage.

Formwork is installed around the reinforcement so that in place of the support it turns out, as it were, wooden box. Its inner surface can be moistened with water, so that the concrete will not be absorbed into the boards and subsequently the formwork will be easier to remove. Inside the box, concrete is poured in several stages, 20-40 mm per layer. In order to avoid the formation of air pockets inside the supports, each time the concrete must be broken using a vibrator.

Pouring should be done within one day so that a seam does not form at the junction of the concrete layers. It is necessary to control that all supports are the same height above ground level.

Flood columnar foundation recommended only during warm seasons, it is undesirable to leave it unloaded for the winter, as it can undergo serious deformation and even destruction.

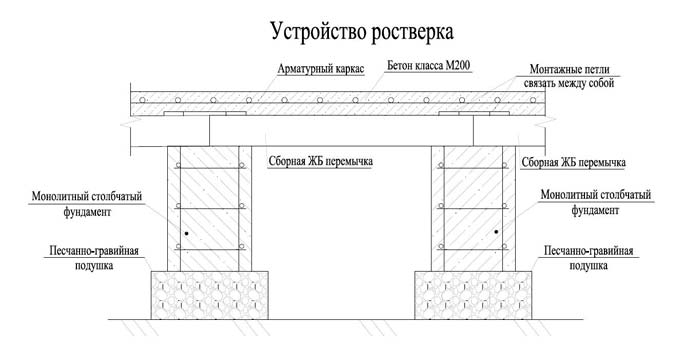

Calculation and construction of the grillage

The construction of a monolithic grillage can guarantee the rigidity and stability of the foundation. Correctly carried out calculations of the width of the grillage and required thickness fittings ensure the reliability of the entire structure. When carrying out calculations, it should be taken into account that the foundation will be punched along the pyramid, and the sum of the reactions of all piles will be equal to the punching force.

For the device of the grillage, it is necessary to use reinforcement or wire, which will connect all the supports to each other. Then, formwork should be made around the entire perimeter and poured with concrete, the surface of which is then carefully leveled.

Foundation insulation and waterproofing

The distance from the ground to the base of the house should be protected from wind, snow, rain. For this purpose, it is plinth installation, which can be assembled from boards, timber, bricks, polystyrene foam or foam blocks. This allows you to insulate the inner surface of the foundation and avoid freezing the floor in the house in winter.

The distance from the ground to the base of the house should be protected from wind, snow, rain. For this purpose, it is plinth installation, which can be assembled from boards, timber, bricks, polystyrene foam or foam blocks. This allows you to insulate the inner surface of the foundation and avoid freezing the floor in the house in winter.

Regardless of what material the plinth will be made of, it is necessary to remember about the installation of ventilation holes with a diameter of at least 100 mm, which will help prevent the occurrence of dampness and mustiness under the floor of the house. In winter, these openings can be closed with plugs to keep the house warm.

Would you like to suggest photos for publication on a topic?

Please help us make the site better! Leave a message and your contacts in the comments - we will contact you and together we will make the publication better!

The choice of the type of foundation for any structure is determined by local conditions. It is impossible to say that this design is the most common. A columnar foundation with a grillage is somewhat behind in popularity the most commonly equipped one, however, sometimes it is more expedient to build it all the same.

Experts give the palm in the invention of this “mixed” design to the Finns. And it is called mixed because such a pile foundation also has elements of a strip base. It has its own advantages, which determine the specifics of the application. Suffice it to say that the cost of its construction is about 4 times lower compared to a monolith. By the way, there are other names for this design - column-tape and column-grillage.

Peculiarities

- Relatively low cost, as the consumption of materials is small.

- Possibility of their choice. Such a base is mounted not only from reinforced concrete products. Pillars are also erected from brick, stone, in some cases even from wood (for example, larch, cedar, oak).

- No basement. Therefore, a columnar foundation is more suitable for industrial, warehouse or outbuildings (for example, sheds, baths). It is equipped for residential buildings if another type of foundation is not suitable. For example, water underground layers are located close to the surface of the earth. It is clear that in this case it makes no sense to mount the tape base. Although for small country houses such a foundation is an excellent option for any soil.

- Ease of construction and low labor intensity.

- Ease of construction. You do not have to dig a pit (as for a slab) or a large trench (for a monolithic or prefabricated tape).

- A columnar-grillage foundation, unlike a strip or slab foundation, can be built on terrain with complex terrain, even on slopes.

Consider the most durable option - on reinforced concrete pillars. But first, it’s worth explaining what a grillage is.

These are foundation elements that are designed to connect the "tops" of all pillars into a single rigid structure. For this, beams or slabs are used, located not in trenches, but on the surface of the earth.

These foundations, depending on the location of the pillars relative to each other, are divided into single and cluster, and from their installation - into hanging and "racks", buried or not buried. They, like tape, are monolithic or prefabricated. It depends on the conditions of further operation, which determines the way the grillage is constructed.

Consider one of the construction options in in general terms, since the nuances are determined by local conditions, therefore, for each specific structure, certain design features of such a foundation will be selected.

Before proceeding with the installation, it is necessary to carry out a number of preparatory measures, and first of all, to make calculations. But this is a separate big topic, so let's go directly to the production of work. And consider the simplest installation method.

Technology

Site preparation

Marking is done along the perimeter of the future building (), and then the top layer of soil is removed (“tape”). After that, holes are dug in the places determined by the project for the installation of pillars. The depth should exceed the level of freezing of the soil in the area, plus 25 - 30 cm in order to then backfill (the so-called "pillow").

When determining the dimensions of the pits, it must be taken into account that the pillar of the calculated dimensions will be mounted in the formwork, and its walls also have their own dimensions (board thickness, 1 on each side of the square). In addition, the supporting frame still needs to be installed in place, and then strengthened with spacers.

After all the pits are ready, their bottom is backfilled with a mixture of coarse sand and fine gravel, after which such a “cushion” is compacted. To increase the density, it is also advisable to spill it with water.

Last event on this stage- bottom waterproofing. This must be done for 2 reasons. Firstly, in the process of pouring the solution, moisture will not go into the ground, which can disrupt the natural hardening process and reduce the strength of the structure. Secondly, the laid material during the operation of the building will play the role of cut-off insulation, preventing the penetration of moisture from the soil into the concrete pillars.

Roofing material is usually used, but its service life does not exceed 4-5 years. Therefore, it is better to work with polyethylene or something similar.

formwork

As a rule, it is made removable. The cheapest option is to use "twenty" boards. Boxes are knocked down from them and installed in pits. Then - spacers.

Sometimes the formwork is not done if the earth in the pit is dry, hard, and it is dug exactly to the size of the post. It is enough just to lay out its walls and bottom with a moisture-proof material, and you can pour the solution.

The formwork is removed after 4 - 5 days, when the concrete "grabs".

Reinforcement

It is necessary to strengthen the concrete pour. Such frames are harvested outside the pit and then lowered into it. Since they are assembled from a metal bar, it must be protected from corrosion. To exclude direct contact with the liquid, the size of the reinforcing structure is selected so that after pouring the concrete, its layer between the walls of the formwork (pit) and the bars is at least 5 cm on each side. Even if later somewhere the pillar partially crumbles, the bars will not “be exposed”.

Their connection is made only by "viscous". Welding leads to overheating of the metal, which “pointwise” changes its structure and reduces strength in these places.

It should be noted that the vertical bars must be above the fill level, as they will be connected to the grillage.

Pouring solution

There is also such a nuance. You can not fill the formwork in parts. For example, half today and the rest the next day. The fact is that during the night the loaded concrete will partially “grab”, and a seam will form between it and the second half of the pour. In this case, there is no need to talk about the strength of the monolith of the structure.

Outdoor post processing

After dismantling the formwork, the upper sections concrete structures protected by a layer of waterproofing (hydrostekloizol, bitumen, etc.), thermal insulation, after which the pits are filled up. If the soil is from the category of heaving, then it is better not to use this earth, but to take, for example, coarse sand.

Installation of the grillage

It is done either on the ground or above it. Supporters of the second option argue that this method excludes any effect of the soil (as well as moisture) on the grillage.

To raise the grillage, you need to increase the thickness of the sand backfill (although there are other options). And if it is mounted on the ground, then it is necessary to dig shallow trenches so that the upper edge of the “cushion” is at ground level. Nothing complicated.

All activities are identical to those described above - sealing the pillow and mortar, the dimensions of the reinforcing assembly. After the "seizure" of the concrete with the "hanging" grillage, the "cushion" is removed.

Do not forget that the reinforcement frame must be securely connected to the ends of the vertical bars left during the installation of each column.

Some rules

- Pillars (supports) must be installed at all “nodal” points (crossings or junctions of walls, corners of a structure).

- The optimal distance from pole to pole is from 2.5 to 3.5 m. An increase in it can lead to the destruction of the grillage, and a decrease will increase the consumption of building materials (and labor costs).

- Such foundations are well suited for areas with irregularities that it is not possible to “smooth out” or it is impractical to do this for some reason. They are also settled in areas with a large freezing depth or high groundwater.

- It is much easier to build a prefabricated structure, and it will take much less time. But if a large load is assumed, then a monolithic foundation is mounted.

- If you equip a fixed formwork from foam boards, then this design will increase the life of the pillars. The material will simultaneously protect against freezing, and from moisture, and from loads due to systematic soil movements.

- The formwork option for the "hanging" grillage is as follows. Bricks are laid along the perimeter, on which formwork is installed, but with a bottom (from boards). Then it is easy to dismantle it.

- Before putting the hammered formwork into place (into the pit), it must be well moistened with water. Firstly, then it can be easily removed, as it will not stick to concrete. Secondly, the boards will not “pull” water out of it.

For small buildings with a volumetric weight of about 1000 kg / m 3, one of the best solutions is a foundation of pillars located in the ground at a certain depth. Telling about how to build a columnar foundation with your own hands step-by-step instruction It is quite suitable even for a person who owns elementary construction skills.

To do this, it is necessary to carefully and correctly select materials, calculate and familiarize yourself with the construction technology in all details.

Based on the reviews of developers, the advantages of a columnar foundation are as follows:

- a large selection of varieties of materials that allow you to properly distribute the load;

- reasonable cost and low consumption of materials;

- small amount of construction;

For heavy buildings and with a high level of groundwater, a columnar foundation is not suitable.

How to calculate the foundation

When designing a house on your own, you always know what materials it will be built from.

1. Determination of loads on the house. The weight of all parts of the building is easy to determine. Seasonal loads and the weight of the objects inside are added to them. It also takes into account the influence of the grillage, usually made of reinforced concrete with a bulk density of 2400 kg/m 3 .

2. Assessment of the nature of the soil. A do-it-yourself columnar foundation for a house is usually erected without laboratory studies of the composition and properties of the soil. The main indicator is its resistance, which is determined from the tables and is in the range of 1-6 kg / cm 2. Its value depends on the composition and porosity of the soil.

3. Number of supports. The bearing capacity of the pillars depends on the area of \u200b\u200bthe supporting surface. Usually used. It is desirable that they have an extension (shoe) at the bottom. It is important to consider the composition of the concrete mix and reinforcement. The step between the supports depends on the calculation and does not exceed 2.5 m. They must be present at all corners, at the junction of walls, under beams and in places of concentrated loads.

foundation material

You can choose many options for how to build a columnar Materials can be very different, but they must be of high quality. They are as follows:

- wood - for light houses, baths, saunas;

- red brick - for medium-sized houses;

- - for buildings with weighted parts;

- reinforced concrete - for heavy buildings.

Pillar foundation with grillage. Step by step instructions for construction

The construction of houses is not so difficult when all the work is divided into separate and interconnected steps, smoothly passing one into another. If a columnar foundation is being built with your own hands, a step-by-step instruction should include all stages of work:

1. Preparation. The construction site is cleared and a layer of black soil is removed under the base. If there is soil containing clay under it, it is necessary to backfill a layer of sand with gravel.

The site is leveled horizontally using a level. It provides a convenient access for vehicles with materials and mixers with concrete.

2. Marking up the plan of the house. First, mark the contours of the building and places under the pillars, which are located strictly along the axes. The corners of the foundation of the house must be straight. The correctness of the breakdown along the center lines is checked, as well as the lower elevation of the trench for compliance with the design one.

3. Digging holes for poles. The foundation is shallow (70-100 cm) and standard (from 100 cm). The first option is better suited for rocky and sandy soil. In a clayey and wet area, the pillars must be buried to a great depth. It is not necessary to dig holes: if possible, poles are driven in or screw piles are screwed in. The most common and cheapest way is to drill wells and fill them with concrete.

4. Concreting. At the bottom of the pit, a pillow is laid from a mixture of sand and gravel. The pillars are concreted directly into the ground when it does not crumble. In all other cases, formwork is installed from the following materials:

Boards not more than 155 mm wide, planed on the concrete side.

Finished metal shields.

Pipes are ceramic, asbestos-cement or metal. Numerous reviews speak of the benefits of using pipes, especially on shear-prone and loose soil.

Ruberoid, rolled up and reinforced with wire or outside.

Rolled waterproofing is lined at the bottom with an overlap on the walls to prevent the solution from flowing out through the cracks of the formwork.

5. Installation of fittings. The pillars are reinforced in the longitudinal direction with steel bars. They are installed vertically in the pit and tied with clamps. Part of the reinforcement should protrude 15-30 cm above the foundation for further connection with the grillage.

6. Installation of poles. If the supports are made by laying concrete, it is fed in layers with compaction by a vibrator. There should be no cavities inside to increase strength. Concrete should not be too liquid or thick in order to further provide the necessary strength and prevent cracks. Until the required strength is gained, it is covered with a film and moistened.

When laying out a columnar foundation of brick with your own hands, it is fastened with cement mortar.

Deviation from the horizontal is allowed no more than 15 mm. Correcting distortions in the future will be difficult. When laying, there should not be any gaps.

After hardening, the supports are covered with mastic or bitumen for waterproofing. Coatings are applied in 2 layers with laying between them and outside the strips of roofing material.

Errors when laying the foundation

Developers who build houses on their own should not make miscalculations with foundations that significantly affect the durability of buildings. In most cases, the errors are:

- Uneven subsidence of the structure due to the insufficient depth of the pillars or their different depths.

- Uneven distribution of load on poles.

- The use of poor quality materials for construction.

- The composition and characteristics of the soil have not been assessed.

In order to be able to properly build a columnar foundation with your own hands, the step-by-step instructions must be fully followed during construction.

Manufacturing grillage

To equalize the load on the pillars and prevent the transverse displacement of the house, the instruction for creating a columnar foundation provides for tying the supports into a common monolithic structure using a grillage - horizontal fastening beams. It is equipped at a height from the ground level.

For construction, timber, metal profiles or reinforced concrete are used. Particular attention is paid to the place where the grillage is attached to the pillars, since its reliability determines the stability of the entire building.

For the construction of a reinforced concrete base, a wooden formwork is attached around the perimeter of the structure and at the locations of the load-bearing walls. Inside, a reinforcement frame is installed, firmly connected to the protruding rods of the pillars, and then laid concrete mix. The surface of the grillage is leveled and covered with a film from drying out.

When the concrete gains strength, they arrange waterproofing from above and proceed with the installation of ceilings and cocking walls.

A complete installation instruction for a columnar foundation also includes operations for arranging waterproofing and pick-up.

Waterproofing grillage

Waterproofing is done on top of the grillage. She is equipped different ways of which the following are the most common:

- Bitumen is applied on top and ruberoid is laid interspersed with it.

- A cement mortar mixed with sand 1: 2 is laid out on the grillage. Then roofing material is laid.

Pickup device

The underground space is protected from atmospheric action by the arrangement of a fence - a fence between the supports. It is made of wood, brick or stone. From below, a concrete screed is laid out, which serves as the base. To do this, first make a trench and fill the bottom with sand. For the screed, formwork from boards and a reinforcing cage are installed. The connection of the pick-up with the supports is not done in order to avoid the appearance of cracks in it during the settlement of the house.

They try to make the basement higher, thanks to which the structure looks attractive. It corresponds to the height of the supports.

Column-strip foundation

The base of the pillars, combined with a monolithic concrete frame, combines all the advantages of both types of bases. When a column-strip foundation is being erected, the step-by-step instructions are the same as for the construction with a grillage. The supports penetrate far into the depths, creating reliable protection against seasonal soil movements.

They are rigidly connected with a tape shallow base, passing under bearing walls buildings. The entire structure is poured with concrete at the same time, as a result of which it becomes monolithic and durable. With self-preparation of the solution, the concrete is laid in layers. The use of vibrators is mandatory in order to remove air bubbles from the mass as much as possible.

Conclusion

Various options for a columnar foundation are widely used in private housing construction. It is characterized by high reliability, speed of construction and minimal consumption of building materials.

With basic skills, many developers can build a columnar foundation with their own hands. Step-by-step instructions will help to avoid mistakes and make the base reliable.

Everyone knows what a foundation is, but perhaps many people hear about a grillage for the first time. When constructing a foundation from piles or reinforced concrete pillars grillage device is required. The column-grillage foundation today is the most popular in individual construction, mainly due to quick installation and inexpensive cost. It is worth noting that this type of foundation is not inferior to concrete in terms of strength.

Appropriateness of application

Before considering the question of when and where it is better to use a base of this type, it would not hurt to figure out what a column-grillage foundation is, what it is and when it is still more profitable to use it.

This type of foundation is based on opera pillars (piles or reinforced concrete structures), in order to evenly distribute the loads from the future construction, all the supports are connected into one structure using a grillage, which is laid in the upper part of the base.

If weak soils prevail at the construction site: sandy, sandy loamy clayey, then it is most effective to use a columnar-grillage foundation here. Thanks to it, piles or poles can be immersed to the maximum depth, which will avoid the occurrence of support in unreliable and loose soils.

In conditions where soils have a large freezing depth, the installation of a concrete foundation will be too expensive, therefore, in such areas it is also preferable to use poles with a grillage as supports.

Piles, pillars made of reinforced concrete, wood and metal can be used as supports. The last two options are used extremely rarely and only for light outbuildings. Most often, reinforced concrete is used for supports of a columnar-grillage base.

How to make calculations

Before engaging in the construction of any foundation, it is necessary to carry out soil surveys and perform foundation calculations. This step is the most important. So, the device of the column-grillage foundation begins:

- each corner of the future building should be supported by a pillar;

- the sections where the walls intersect should be reinforced with additional pillar supports;

- as for the straight sections, then 2.5 m is quite a sufficient distance between the supports that meets all the requirements, but more than 3.5 m should not be chosen, since such a distance is already insufficient.

The initial stage of all preparatory work begins with the removal of sod over the entire area of \u200b\u200bthe future base. Further, in places where the pegs are driven in, they dig holes for the supports. The depth of the pits should be greater than the amount of soil freezing plus 20 cm for the middle strip. Additional centimeters are necessary in order to arrange a pillow, which in the future will contribute to the correct distribution of loads. The width of the trench will be equal to the width of the wall of the future building. From this size, on each side of the column, plus another 20 cm is set aside and the formwork is installed.

The construction of a columnar-grillage foundation begins with the installation of a cushion of slag or rubble, which must be carefully compacted. The material must be laid across the entire width of the pit. A ruberoid is laid over the compacted slag. This requirement is due to the fact that moisture from the concrete solution is not absorbed into the ground while it is gaining strength.

How to make formwork

For these purposes, ordinary boards are suitable, a thickness of 2 cm will be enough. Light weight makes installation easy and they are inexpensive. Shields are made of them, then boxes. Then they are installed in prepared trenches. Be sure to thoroughly moisten the surface of each shield with water. This will prevent moisture from being drawn out of the concrete, and in the future will facilitate the dismantling of the formwork.

Instead of boards, pipes made of asbestos or ceramics can be used. After pouring and hardening of the solution, they are left in the ground. It is allowed to completely avoid the installation of formwork if the solid walls do not crumble in the prepared trench, and the size fully corresponds to the calculations made. In order to prevent moisture from the concrete solution from being absorbed into the ground, it is enough to isolate the walls with a simple plastic film. But it is still better to use formwork for safety net.

How to reinforce foundation pillars

The column-grillage foundation for gas silicate must be carried out with the obligatory reinforcement of the supports under it. Reinforcing bars are used for the skeleton. The diameter will fit both 10 and 14 mm. Stepping back from the edge of the trench 5 cm, the reinforcement is placed in the pit and welded to the horizontal bars.

The distance between the horizontal rods is about 40 cm. It is important to remember that the longitudinal rods along the length should be such that after pouring the entire amount of the solution, the rods have free ends equal to at least 30 cm. (Usually leave 30-40 cm). It is better to leave more than less, since extra centimeters can always be cut off. To these ends, the framework of the grillage made of reinforcement will be further welded. The reinforcing skeleton should be assembled directly on the ground, and only then, in a finished assembled form, lowered into a dug trench.

Pouring concrete mortar

When the formwork is exposed and the metal skeleton is lowered into the trench, you can start pouring concrete. It is poured in layers. The thickness of each is approximately 30 cm. Each poured layer must be bayoneted to remove excess air and make the concrete dense and durable.

Fill technology is as follows. The first layer is poured, carefully bayoneted manually or with a tool, then the next one is poured. It is highly not recommended to fill in half of the mortar today and the other tomorrow, since a butt joint will appear at the pole at the junction, reducing its bearing capacity.

Formwork can be removed after 4 days. The surface of each support must be covered with waterproofing or treated with a special material. Only after that, the support can be covered with earth. If the site is predominantly loose clay soil, then it is better not to return it to the pit, but to fill it with sand with careful tamping.

Installation of the grillage

The use of a column-grillage foundation allows the grillage to be mounted both from monolithic and precast concrete. You can often hear a variety of opinions about how far from the ground the grillage should be located directly. But its depth is determined by several parameters. For example, it is unacceptable to mount the grillage close to the ground level, when loose and heaving soils predominate in the areas.

And the grillage is laid in the formwork prepared in advance, which ties together all the supporting pillars. A layer of sand is poured onto the bottom of the formwork (it is advisable to use larger fractions) and carefully compacted.

In the second stage, a metal frame is made, which is laid in a mold and welded to the ends of the remaining reinforcement of the supports themselves. Next, pour the solution, removing air from it. When the solution has completely hardened, the formwork is removed, along with a layer of sand. As a result, the column-grillage foundation, which can last for many decades, is completely ready. The most important thing is to comply with all calculations and requirements, especially when soil surveys are being carried out on the site for construction.

The quality of the foundation determines how strong and durable the building will be. Now advanced technologies are used in construction, which allow quickly and efficiently erecting any structure. These include a columnar foundation with a grillage, the price of which is quite low.

There are several classifications of foundations, from which you can easily choose the option that suits the consumer. After all, not all types of soil can build a building. Especially since specifications (depth, material used) have a significant impact on the quality of the future construction.

Depending on the material used for construction, they can be:

- stone (rubble, brick, rubble concrete);

- reinforced concrete (they are divided into prefabricated and monolithic);

- wooden.

The columnar foundation is laid below the depth of freezing of the soil, otherwise the piles can be pushed out by frost heaving

Bytype of construction they are divided into:

- tape;

- slab (solid);

- columnar;

- pile.

In suburban construction, due to the ease of installation and the availability of materials, columnar and tape types are most often used.

Tape

Based on the name, it is easy to guess that it is a tape around the entire perimeter of the building. Such types, in turn, are divided into prefabricated and monolithic.

The tape base is often used, because on such a foundation it is possible to build any house, starting from a monolithic one and ending with a wooden one, without large financial and physical costs.

The tape type has a lot of advantages:

- a small price, but compared to a columnar foundation with a grillage, the cost is slightly higher;

- stability;

- long service life;

- the possibility of carrying out work at any time of the year;

- versatility - the ability to use for buildings of any type.

The scope of its application is the construction of foundations for brick and block houses.

The scope of its application is the construction of foundations for brick and block houses.

Slab (solid)

This view is placed under all superstructures in the form of a slab. It is used for building multi-storey buildings, where it is required to redistribute the load on the base, while reducing the load on weak areas of the soil and increasing the strong areas.

If on site high level groundwater located on weak soils is best view . It is resistant to any type of deformation and can perfectly cope with the heaviest loads without any loss of functionality. In addition, its service life is quite long.

But compared to other types, the construction slab foundation do-it-yourself is a laborious process that requires financial investments.

Columnar

This type of foundation is one of the best solutions for the construction of small structures in the form of baths, verandas and others. wooden houses frame type.

The columnar foundation is the least expensive in terms of labor intensity and finances

If the project does not provide for the construction of basements, the load on the soil is very small. Therefore, the columnar foundation is here, as nowhere else by the way. Besides, the price of a columnar foundation with a grillage, provided that it is erected by one's own hands, is quite insignificant.

Therefore, in country construction it is better to use this fast method without compromising quality along the way. The price for the construction of a columnar foundation with a grillage with your own hands is 75% less than a similar strip foundation.

pile

For a non-professional, building a pile foundation with your own hands is quite difficult. More often it is used to build buildings on weak soils. Moreover, it is subdivided into piles-racks and hanging piles. Depending on how the load is transferred to the ground, one type or another is used.

A pile foundation with a recessed grillage is a special type of foundation, which is particularly durable. It is most often used in the construction of aerated concrete and brick buildings.

More details about the features of each type of foundation and its price can be found in the table:

| Difficulty rating | Reliability assessment | Deadlines (days) | Price (thousand rubles per 1m2) | Main advantage | Main disadvantage | |

| Pile-screw foundations | 3 | 8 | 1-2 | 100 | price-term combination | the impossibility of laying on rocky soils |

| slabfoundation | 6 | 9 | 35 | 570 | reliable | high price |

| Column Foundation | 4 | 3 | 10 | 280 | ease of bookmarking | uneven load leading to the destruction of the building |

Rostverk: what is it?

The grillage is part of the columnar foundation, located at the top and distributing the entire load. In addition, it is a kind of support for the entire structure. In appearance, it is a beam that unites the heads of the pillars.

The grillage is part of the columnar foundation, located at the top and distributing the entire load. In addition, it is a kind of support for the entire structure. In appearance, it is a beam that unites the heads of the pillars.

Foundations with a grillage can be of the following types:

- tape;

- solid.

The choice depends on:

- soil;

- materials used;

- device methods.

A wooden grillage for a columnar foundation is widely used in summer cottage construction. This is the ideal type of foundation for building wooden house, baths, verandas, etc. But it can be made not only from wood, but also from other materials. Although, of course, its price will be much higher.

How to make a columnar foundation with a grillage with your own hands

Many summer residents ask the question of how to make a columnar foundation with a grillage for a bathhouse or a veranda with their own hands. This is not as difficult as it might seem at first.

A self-made pile has a low bearing capacity, therefore careful calculation of loads is important

The technological process includes the following steps:

- calculation;

- execution of land works;

- production of formwork for pillars;

- reinforcement of a columnar foundation with a grillage;

- pouring concrete;

- grillage device.

Calculation

This stage is the most important, because the reliability and strength of the whole building depend on it. Calculations can be easily performed using special tables. They can be easily found on the Internet.

Land works

As in any construction, site preparation has great importance and takes a lot of money and effort.

The main works are as follows:

- clear the site of any vegetation;

- mark the territory, and dig a shallow hole along the entire length and width;

- mark the places where the pillars will be located, make recesses;

- fill the pits to the level of freezing of the ground plus 20 cm under the pillow;

- lay a pillow there, consisting of gravel and sand.

With a small construction, you can easily get by with improvised tools without using special equipment.

Production of formwork for pillars

Metals or wood are used as formwork. For summer cottage construction, it is cheaper and easier to use the latter construction material. The thickness of the wood must be more than 2 cm.

The works are as follows:

- assemble the prepared boards into shields, from which it will be necessary to make boxes;

- put the resulting structures in pits;

- moisten the formwork with water.

As a formwork, asbestos pipes are perfect, which are distinguished by their low price and excellent quality.

Reinforcement of a columnar foundation with a grillage

For these purposes, rods with a cross section of 1-1.6 cm are used. However, their dimensions must be selected in accordance with the grillage frame. Assembly is done outside. The rods are fastened with horizontal jumpers by welding or tying. The last option is the easiest.

It is preferable not to weld the fittings, but to tie them, but in home construction, welding is more often used.

It is preferable to use rods with a diameter of 6 mm. They are installed in increments of 30-40 cm. Vertically, the reinforcement is connected using a reinforced grillage mesh. Therefore, at first it costs a little of it raise, above the head of the column by 30-40 cm, and then, after completion of the assembly work, strengthen in the recess for the post.

Pouring concrete

Further actions will not take much time: the dug hole must be filled with concrete. And this process should be divided into several stages: pour a layer about 25 cm thick, pierce, and level everything, removing air pockets that reduce the stability of the building.

grillage device

It can be different in height, located both above the ground and directly in the ground. Which is better is hard to say. There is no consensus on this issue.

The sequence of actions is as follows:

- make formwork between all elements along the entire length. For this, sand is used;

- close the sand, for example, with plastic wrap;

- make and put a frame in the formwork;

- weld or tie the pile rods, combining them with the grid of the grillage;

- pierce the solution with reinforcement, removing excess air bubbles;

- when the concrete dries, the formwork can be removed;

- remove the layer of sand;

- strengthen the resulting structure with brick supports.

So, the process of creating a columnar foundation with a grillage for frame house or other buildings can be easily done with your own hands. This is the simplest and most cost effective solution.

The price of a columnar foundation with a grillage

The cost of the finished product of this type is the lowest. In general, it depends on the volume of construction work and the price of materials. . The price of a columnar foundation with a grillage also depends on the foundation construction technology and the depth of the foundation. Average the price is from 25000 rubles (building 6X6). The price does not include land works, more precisely leveling the site.

Of course, if you do everything yourself, the cost will be much lower.

You can see more about how to make a columnar foundation with a grillage with your own hands in the video: