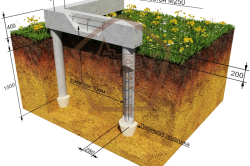

For small buildings with a volumetric weight of about 1000 kg / m 3, one of the best solutions is a foundation of pillars located in the ground at a certain depth. A step-by-step instruction telling about how to build a columnar foundation with your own hands is quite suitable even for a person who owns elementary construction skills.

To do this, it is necessary to carefully and correctly select materials, calculate and familiarize yourself with the construction technology in all details.

Based on the reviews of developers, the advantages of a columnar foundation are as follows:

- a large selection of varieties of materials that allow you to properly distribute the load;

- reasonable cost and low consumption of materials;

- small amount of construction;

For heavy buildings and with a high level of groundwater, a columnar foundation is not suitable.

How to calculate the foundation

When designing a house on your own, you always know what materials it will be built from.

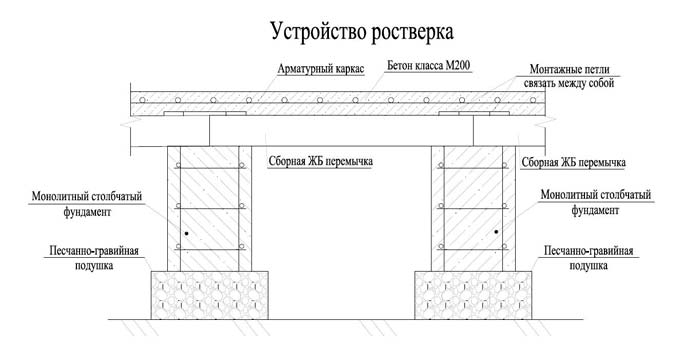

1. Determination of loads on the house. The weight of all parts of the building is easy to determine. Seasonal loads and the weight of the objects inside are added to them. It also takes into account the influence of the grillage, usually made of reinforced concrete with a bulk density of 2400 kg/m 3 .

2. Assessment of the nature of the soil. Column Foundation for a house with their own hands, it is usually erected without laboratory studies of the composition and properties of the soil. The main indicator is its resistance, which is determined from the tables and is in the range of 1-6 kg / cm 2. Its value depends on the composition and porosity of the soil.

![]()

3. Number of supports. The bearing capacity of the pillars depends on the area of \u200b\u200bthe supporting surface. Usually used. It is desirable that they have an extension (shoe) at the bottom. It is important to consider the composition of the concrete mix and reinforcement. The step between the supports depends on the calculation and does not exceed 2.5 m. They must be present at all corners, at the junction of walls, under beams and in places of concentrated loads.

foundation material

You can choose many options for how to build a columnar Materials can be very different, but they must be of high quality. They are as follows:

- wood - for light houses, baths, saunas;

- red brick - for medium-sized houses;

- - for buildings with weighted parts;

- reinforced concrete - for heavy buildings.

Pillar foundation with grillage. Step by step instructions for construction

The construction of houses is not so difficult when all the work is divided into separate and interconnected steps, smoothly passing one into another. If a columnar foundation is being built with your own hands, a step-by-step instruction should include all stages of work:

1. Preparation. The construction site is cleared and a layer of black soil is removed under the base. If there is soil containing clay under it, it is necessary to backfill a layer of sand with gravel.

The site is leveled horizontally using a level. It provides a convenient access for vehicles with materials and mixers with concrete.

2. Marking up the plan of the house. First, mark the contours of the building and places under the pillars, which are located strictly along the axes. The corners of the foundation of the house must be straight. The correctness of the breakdown along the center lines is checked, as well as the lower elevation of the trench for compliance with the design one.

3. Digging holes for poles. The foundation is shallow (70-100 cm) and standard (from 100 cm). The first option is better suited for rocky and sandy soil. In a clayey and wet area, the pillars must be buried to a great depth. It is not necessary to dig holes: if possible, poles are driven in or screw piles are screwed in. The most common and cheapest way is to drill wells and fill them with concrete.

4. Concreting. At the bottom of the pit, a pillow is laid from a mixture of sand and gravel. The pillars are concreted directly into the ground when it does not crumble. In all other cases, formwork is installed from the following materials:

Boards not more than 155 mm wide, planed on the concrete side.

Finished metal shields.

Pipes are ceramic, asbestos-cement or metal. Numerous reviews speak of the benefits of using pipes, especially on shear-prone and loose soil.

Ruberoid, rolled up and reinforced with wire or outside.

Rolled waterproofing is lined at the bottom with an overlap on the walls to prevent the solution from flowing out through the cracks of the formwork.

5. Installation of fittings. The pillars are reinforced in the longitudinal direction with steel bars. They are installed vertically in the pit and tied with clamps. Part of the reinforcement should protrude 15-30 cm above the foundation for further connection with the grillage.

6. Installation of poles. If the supports are made by laying concrete, it is fed in layers with compaction by a vibrator. There should be no cavities inside to increase strength. Concrete should not be too liquid or thick in order to further provide the necessary strength and prevent cracks. Until the required strength is gained, it is covered with a film and moistened.

When laying out a columnar foundation of brick with your own hands, it is fastened with cement mortar.

Deviation from the horizontal is allowed no more than 15 mm. Correcting distortions in the future will be difficult. When laying, there should not be any gaps.

After hardening, the supports are covered with mastic or bitumen for waterproofing. Coatings are applied in 2 layers with laying between them and outside the strips of roofing material.

Errors when laying the foundation

Developers who build houses on their own should not make miscalculations with foundations that significantly affect the durability of buildings. In most cases, the errors are:

- Uneven subsidence of the structure due to the insufficient depth of the pillars or their different depths.

- Uneven distribution of load on poles.

- The use of poor quality materials for construction.

- The composition and characteristics of the soil have not been assessed.

In order to be able to properly build a columnar foundation with your own hands, the step-by-step instructions must be fully followed during construction.

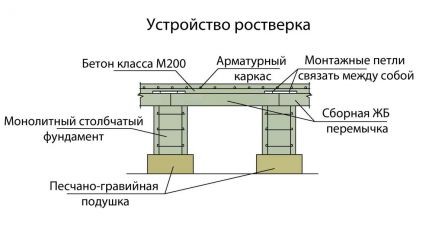

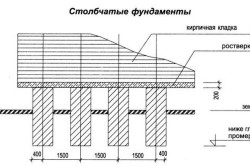

Manufacturing grillage

To equalize the load on the pillars and prevent the transverse displacement of the house, the instruction for creating a columnar foundation provides for tying the supports into a common monolithic structure using a grillage - horizontal fastening beams. It is equipped at a height from the ground level.

For construction, timber, metal profiles or reinforced concrete are used. Particular attention is paid to the place where the grillage is attached to the pillars, since its reliability determines the stability of the entire building.

For the construction of a reinforced concrete base, a wooden formwork is attached around the perimeter of the structure and at the locations of the load-bearing walls. Inside, a reinforcement frame is installed, firmly connected to the protruding rods of the pillars, and then laid concrete mix. The surface of the grillage is leveled and covered with a film from drying out.

When the concrete gains strength, they arrange waterproofing from above and proceed with the installation of ceilings and cocking walls.

A complete installation instruction for a columnar foundation also includes operations for arranging waterproofing and pick-up.

Waterproofing grillage

Waterproofing is done on top of the grillage. She is equipped different ways of which the following are the most common:

- Bitumen is applied from above and ruberoid is laid interspersed with it.

- A cement mortar mixed with sand 1: 2 is laid out on the grillage. Then roofing material is laid.

Pickup device

The underground space is protected from atmospheric action by the arrangement of a fence - a fence between the supports. It is made of wood, brick or stone. From below, a concrete screed is laid out, which serves as the base. To do this, first make a trench and fill the bottom with sand. For the screed, formwork from boards and a reinforcing cage are installed. The connection of the pick-up with the supports is not done in order to avoid the appearance of cracks in it during the settlement of the house.

They try to make the basement higher, thanks to which the structure looks attractive. It corresponds to the height of the supports.

Column-strip foundation

The base of the pillars, combined with a monolithic concrete frame, combines all the advantages of both types of bases. When a column-strip foundation is being erected, the step-by-step instructions are the same as for the construction with a grillage. The supports penetrate far into the depths, creating reliable protection against seasonal soil movements.

They are rigidly connected with a tape shallow base, passing under bearing walls buildings. The entire structure is poured with concrete at the same time, as a result of which it becomes monolithic and durable. With self-preparation of the solution, the concrete is laid in layers. The use of vibrators is mandatory in order to remove air bubbles from the mass as much as possible.

Conclusion

Various options for a columnar foundation are widely used in private housing construction. It is characterized by high reliability, speed of construction and minimal consumption of building materials.

With basic skills, many developers can build a columnar foundation with their own hands. Step-by-step instruction help to avoid mistakes and make the foundation reliable.

The construction of any house begins with the choice of the type of foundation that is most suitable in order to provide the future structure with a reliable foundation. Large cottages and houses with massive walls need a monolithic strip foundation buried in the ground around the entire perimeter of the house by at least two meters.

In contact with

The cost of building such a foundation is very high and amounts to almost a third of the cost of the house itself. But for wooden and frame houses, in which the presence of a large basement is not expected, a more rational option would be a columnar-grillage foundation. Its cost is much cheaper, and if the technology is followed at all stages of construction, it will ensure uniform settlement of the entire structure of the house.

Types of columnar foundations

Before starting to build the foundation, it is necessary to carry out all the required geological surveys, determine the type of soil on the surface and at a depth of up to 2 meters, the presence of groundwater, the depth of freezing. Using the results obtained, you can choose the type of columnar foundation.

On heaving soils, it is recommended to use reinforced concrete blocks interconnected with reinforcement as supports. In the event that the soil is not very heaving, reinforced blocks can be used. And if the soil is not prone to swelling, then it is possible to use free concrete supports.

Depending on the level of deepening, columnar foundations are divided into the following types:

- unburied;

- shallow;

- heavily recessed.

The supports that form the basis of the foundation can be made of:

- concrete;

- tree;

- bricks;

- asbestos-cement pipes;

- screw piles.

The choice of the type of supports should be made based on calculations of the future load of the house, its size, the approximate number of people who will live in it and the type of soil. The most common type of supports are concrete pillars reinforced with reinforcement.

Preparatory stage

Before starting the construction of the foundation, it is necessary prepare the site. Loose bulk soil must be properly compacted with a rammer or dig a small foundation pit. In the event that the soil is characterized by subsidence, it is necessary to lay the foundation below the freezing depth by 30-40 centimeters.

It is good if the construction site has a slight slope that provides a runoff of rainwater and melted snow. The layer of the vegetative layer of the soil should first be removed to a depth of about 20 centimeters.

The foundation supports must certainly be located at the corners of the future building, at the intersection of the walls and under the main load-bearing elements of the entire structure. Even at the marking stage, all work must be carried out in accordance with the plan of the future home, since mistakes can lead to serious consequences.

Marking begins with the inner contour, hammering the first peg in place of the future corner of the house. Then, using the construction triangle, the parameters of the outer sides of the foundation are determined. Their dimensions are equal to the lengths of the longitudinal and transverse walls. At the intersection of the axes, 2 and 3 pegs are hammered. And after that, the following corners of the house are determined in the same way.

At the end of the installation of the markup, it is necessary to check its correctness using a goniometer. You should also measure the length of the walls, they must necessarily match the parameters specified in the project of the house.

Device

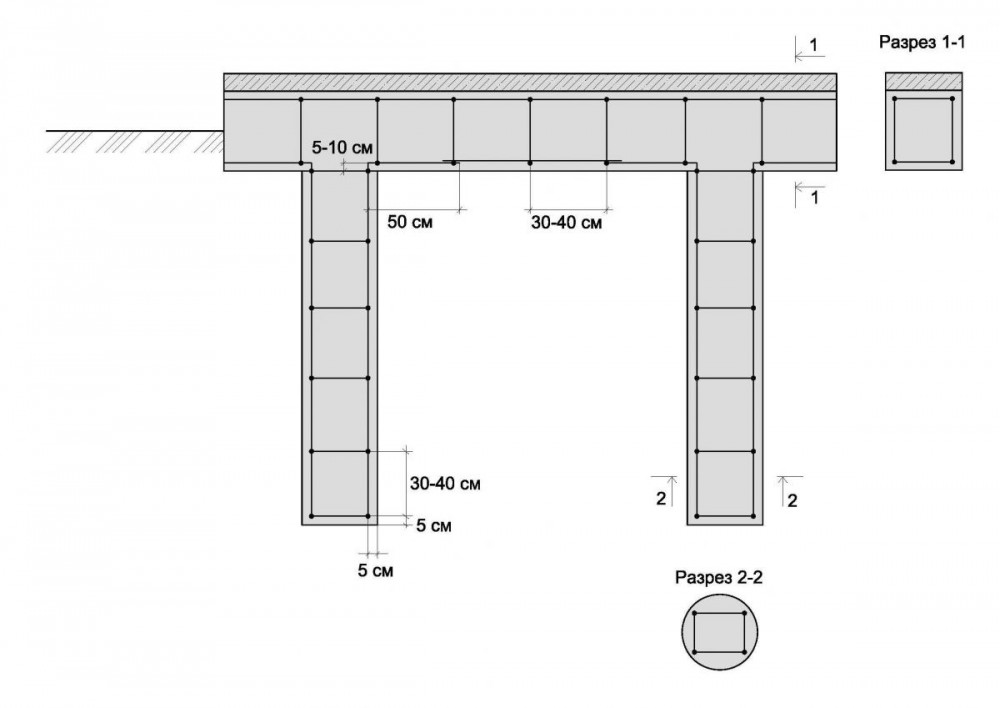

![]() The next step in the construction of the foundation will be earthworks. It is necessary to dig a hole slightly larger than the size of the foundation. Then install the formwork and reinforcement with a thickness of 10-14 mm. Reinforcement bars must be fastened together with reinforcement 6 mm thick and must come out of the foundation to the surface. This is necessary for their subsequent binding to the grillage.

The next step in the construction of the foundation will be earthworks. It is necessary to dig a hole slightly larger than the size of the foundation. Then install the formwork and reinforcement with a thickness of 10-14 mm. Reinforcement bars must be fastened together with reinforcement 6 mm thick and must come out of the foundation to the surface. This is necessary for their subsequent binding to the grillage.

Formwork is installed around the reinforcement so that in place of the support it turns out, as it were, wooden box. Its inner surface can be moistened with water, so that the concrete will not be absorbed into the boards and subsequently the formwork will be easier to remove. Inside the box, concrete is poured in several stages, 20-40 mm per layer. In order to avoid the formation of air pockets inside the supports, each time the concrete must be broken using a vibrator.

Pouring should be done within one day so that a seam does not form at the junction of the concrete layers. It is necessary to control that all supports are the same height above ground level.

It is recommended to fill the columnar foundation only in the warm season., it is undesirable to leave it unloaded for the winter, as it can undergo serious deformation and even destruction.

Calculation and construction of the grillage

The construction of a monolithic grillage can guarantee the rigidity and stability of the foundation. Correctly carried out calculations of the width of the grillage and required thickness fittings ensure the reliability of the entire structure. When carrying out calculations, it should be taken into account that the foundation will be punched along the pyramid, and the sum of the reactions of all piles will be equal to the punching force.

For the device of the grillage, it is necessary to use reinforcement or wire, which will connect all the supports to each other. Then, formwork should be made around the entire perimeter and poured with concrete, the surface of which is then carefully leveled.

Foundation insulation and waterproofing

The distance from the ground to the base of the house should be protected from wind, snow, rain. For this purpose, it is plinth installation, which can be assembled from boards, timber, bricks, polystyrene foam or foam blocks. This allows you to insulate the inner surface of the foundation and avoid freezing the floor in the house in winter.

The distance from the ground to the base of the house should be protected from wind, snow, rain. For this purpose, it is plinth installation, which can be assembled from boards, timber, bricks, polystyrene foam or foam blocks. This allows you to insulate the inner surface of the foundation and avoid freezing the floor in the house in winter.

Regardless of what material the plinth will be made of, it is necessary to remember about the installation of ventilation holes with a diameter of at least 100 mm, which will help prevent the occurrence of dampness and mustiness under the floor of the house. In winter, these openings can be closed with plugs to keep the house warm.

Would you like to suggest photos for publication on a topic?

Please help us make the site better! Leave a message and your contacts in the comments - we will contact you and together we will make the publication better!

The reliability and strength of a columnar foundation with a grillage largely depends on its proper reinforcement. The features of the reinforcement of a columnar foundation, the sequence of work during reinforcement, the requirements for reinforcement, the location of reinforcement in the corners of the building and at the intersection with load-bearing walls are considered. Also shown regulations, according to which construction is underway and lists errors that should not be made during the work.

Features of the reinforcement of the columnar foundation

An increase in the strength and reliability of the foundation is achieved by its reinforcement. Concrete can withstand high compressive loads. Bending or tensile forces, even small ones, break it.

The following loads act on the foundation pillar:

- for compression - the weight of the building;

- to break - in winter, heaving of the soil compresses the walls of the column and tears it up from the sole;

- for fracture / shear, in winter - horizontal ground movements during freezing or in summer - shear of a dense layer along water-saturated or weak soil.

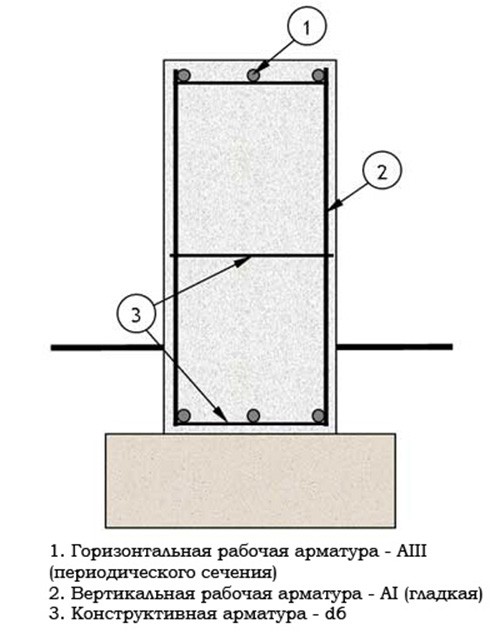

For compressive loads, they do not reinforce, and the effect of heaving of the soil is completely eliminated by wrapping the post with three layers of polyethylene or roofing felt. Shear loading is rarely possible, but it is protected from it by reinforcement.

The second zone of reinforcement in columnar foundations is the grillage. Reinforcement of the pile foundation grillage is carried out only along its lower and upper surfaces, taking into account the thickness of the concrete protective layer.

Requirements for reinforcement of foundation pillars and grillage

For horizontal longitudinal reinforcement of the grillage, bars with a regular profile and a diameter of 10–16 mm are taken. The vertical and horizontal transverse sections of the frame are made of smooth reinforcement, with a diameter of 6 - 8 mm.

For pillars, vertical reinforcement is profiled, horizontal reinforcement is smooth. Same diameters.

Usually, rods of grades A I and A III (A 400 C) are used.

You can use a new type of reinforcement - composite. The practice is not yet great, but its characteristics are good.

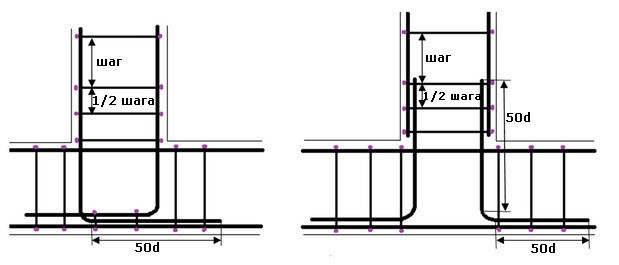

The sequence of reinforcement of pillars and grillage

The pillars are reinforced with vertical bars. They are boiled or knitted with wire into frames.

At the bottom of the pit, sand is poured, 200 - 250 mm thick and on top of the same layer of sand with crushed stone. Lay at least 50 - 100 mm of concrete to protect the metal from ground moisture and corrosion.

Finished frames are lowered into bored piles or pits under poles.

![]()

The cross-sectional dimensions of the frame should be 35–50 mm smaller than the borehole diameter on each side. This layer of concrete is called protective. By alkaline reaction, it protects the metal from corrosion.

The releases of the reinforcement of the pillars in the manufacture of the frame are bent horizontally to a length of 30 - 40 rod diameters. If a certified welder knows how to properly, and without overheating, weld reinforcement, they do not bend.

The rods are laid in the grillage in two layers:

- the top layer is below the top cut by the thickness of the protective layer;

- in the bottom layer, the same thickness above the sole.

The middle is not reinforced, there are almost no loads.

The layout of the reinforcement bars is determined by the requirements for the parts of the foundation:

- for bored piles or reinforced concrete pile columns - the shear strength requirements are determined by the load from the horizontal displacement of soil masses;

- for a horizontal, usually monolithic grillage, the load will be bending, since the grillage beam is located with its ends on supports, and there is almost no support under its middle part.

How are the reinforcement located in the corners of the grillage?

Reinforcing the corners of the pile foundation grillage and the intersection with the carriers interior walls it is necessary to lead with the bending of the rods to a length of at least 0.4 - 0.8 m. The bent parts of the horizontal rods of one side of the grillage must go to the other side perpendicular to it and vice versa.

![]()

It is not always possible to cook - some steel grades are not cooked with conventional electrodes, overheating of the bars, metal leakage and weakening of joints, seams, etc. are possible.

Normative documents on columnar foundations

The number of bars, reinforcement brands, diameters are obtained as a result of the calculation of the columnar foundation by a professional civil engineer. As well as drawings for its reinforcement.

To do this, use the following regulatory documents:

- SP 20.13330.2011 (SNiP 2.01.07-85*) "Loads and impacts" - terminology and loads on a columnar foundation;

- SP 50-101-2004 (updating of SNiPs 2.02.01-83 and 3.02.01-87) - Code of Rules for the foundations of buildings and structures, clauses from 12.1 - to 12.8 - General requirements for calculation, calculation of columnar foundations - clause 12.3;

- SP 22.13330.2011 (updated SNiP 2.02.01-83) "Foundations of buildings and structures" - loads, depth, groundwater accounting, features of design stages;

- SP 63.13330.2012 (updating SNiP 52-01-2003) "Concrete and reinforced concrete structures”, settlement requirements in paragraphs 5, 7, 10.

Calculation according to documents allows you to more accurately determine the price for reinforcing a columnar foundation.

Reinforcement errors

The most common errors:

- The reinforcing cage is installed on the ground. The metal corrodes, expands in volume and tears the concrete in the most important place - the sole of the pillars.

- When installed in a well, the frame is not centered. The reinforcement may come out of the column or a small thickness of the protective layer may remain.

- Reinforcement for connections with the grillage frame is not produced. A monolithic grillage will not be able to withstand horizontal movements of the soil, and the foundation may collapse.

- When welding rods, the joints should not be at the corners and at the intersections of the walls.

- When bending the rods, the place of the bend is not heated - the rod gives microcracks.

- Reinforcement in the middle of any reinforced concrete product- a blunder - a concrete beam or slab is stretched either from above with a load on the edges and a support in the middle, or from below - when the supports are at the edges, and the load is in the middle. These tensile forces must be supported by the reinforcement. There are almost no loads in the middle part of the product, and the reinforcement there is money, time and labor thrown away.

- When pouring concrete, use the deep vibrator only in the inner zone of the frame and carefully so as not to disturb its configuration.

Questions and answers on the topic

No questions have been asked for the material yet, you have the opportunity to be the first to do soIn the field of construction of private residential buildings, a columnar foundation with a grillage has established itself as a reliable and economical option. It is widely used on almost all types of soil. This technology fully admits the possibility of using it to build a foundation with your own hands.

What is a grillage

The grillage is a "superstructure" over the columnar foundation in the form of a reinforced concrete tape installed over the pillars. It increases the stability of the columnar foundation in relation to horizontal displacements and overturning, ensures the joint operation of the pillars as a single structure.

has the following advantages:- possibility of application in case high level groundwater;

- good "performance" on weak and heaving soils;

- it requires a small amount of earthwork;

- has a higher strength compared to the columnar version;

- does not require the use of heavy equipment.

Pole installation

The poles are installed every 2.5–3.5 m.

Important! Mandatory points of support in the corners of the building and at the intersections of walls.

The number of pillars and the area of their base are calculated taking into account the bearing properties of the soil and the total weight of the future building. For the manufacture of pillars, poured concrete with reinforcement is used. Fill options:

- in formwork from boards;

- in the formwork of steel or asbestos-cement pipes;

- without formwork.

The latter option is possible if the soil is dry and the walls of the pit dug under the pole do not collapse.

Formwork for grillage

After all the pillars are installed, the formwork for the tape is prepared. Two parallel rows of boards installed on the edge are fastened along the width of the grillage and installed along the entire perimeter of the foundation. They form the side walls of the formwork.

Important! If the foundation is being built on heaving soil, a gap of at least 15 cm must remain between the concrete and the soil.

Then the soil expanding upon freezing will freely rise within the gap. Without a gap, the connection between the grillage and the pillars may be destroyed or cracks may form in the tape.

If the gap is not needed, the formwork is installed on the ground.

If the grillage is arranged with a gap, its lower surface is limited to a boardwalk. From below, the flooring is supported by boards placed on edge. You can also pour a layer of soil or sand under the formwork and compact it. After stripping, this layer must be removed.

Transverse dimensions of the grillage

The height and width of the grillage depend on the type of structure, wall thickness, and the slope of the site.

For a wooden house

In case of building wooden house(panel or log), the grillage should have a height of 40-60 cm. Then it will have sufficient bending rigidity and provide insulation of the lower part of the building from the zone with high humidity.

Covering the first floor wooden house can rely on:

- on additionally installed poles;

- on the grillage.

In the first case, the width of the grillage corresponds to the width of the wall. In the second, from the inside, its width should be increased to provide support for the floor beams.

When preparing the formwork for the grillage, it is necessary to provide ventilation holes (air vents). Their distance from the surface of the blind area must be at least 30 cm. For this, inserts are made of asbestos-cement pipes or boards.

For a stone house

If a stone house is being built, the width of the grillage is consistent with the width of the wall. This takes into account exterior finish and warming. The minimum height of the tape in this case is 15-20 cm.

Under a stone structure, the grillage connects the support points and provides a solid foundation to support the first rows of masonry. Stone walls have good flexural rigidity in themselves, so the grillage will not experience large flexural loads.

On a site with a slope

If the construction site has a slight slope, the base of the grillage is arranged along the surface and thus the tape will have a variable height.

On a site with a large slope, the grillage can be arranged with steps. The fittings of the pillars should enter the tape by at least 20 cm. In the area of the steps, it is necessary to lay a reinforcing mesh in the masonry. The height of the steps is set such that a whole number of rows of wall masonry fit on it.

Reinforcement

Inside the formwork, reinforcement is placed in two horizontal layers - along the upper and lower edges of the tape. To fix the rods, you can make holes in the formwork and install support transverse rods in them. Immediately after pouring, these bars should be removed from the formwork.

All reinforcement must be installed in such a way that after pouring the distance from the metal to the concrete surface is at least 3 cm.

fill

Important! From the inside, the formwork should be lined with waterproofing material to reduce the loss of "cement milk".

The pouring of the grillage with concrete should be carried out without long breaks. The concrete is laid in layers of 15 cm. The layers can be inclined (30° to the horizontal). To prevent air from remaining between the reinforcement and the formwork, it is necessary to bayonet the concrete with a piece of reinforcement, while simultaneously tapping the formwork from the outside.

When building a columnar foundation with a grillage with your own hands, it is important to pay special attention to the quality of the reinforcement of the tape and the quality of the concrete. The reliability and durability of the foundation of the house will significantly depend on this.

A small video story about the pile-grillage foundation

- Markup and its features

- Land works: nuances

- Foundation concreting

- Installation grillage: recommendations

- Final moments of work

The construction of a private house is always accompanied by the construction of a foundation. There is a huge amount various kinds foundations that are used in various situations. A columnar foundation with a grillage is one of the most optimal options that exist today. This type of foundation is much cheaper than all others that are used in construction.

A columnar foundation with a grillage is not suitable for clay, peat and marshy soils, but it is an ideal economical option for heaving soils.

That is why the column-grillage foundation is currently quite popular. It is quite simple to build it, and you can do it yourself.

All work related to the installation of this type of foundation will be carried out in several successive stages. It is worth talking about each of them in more detail.

Markup and its features

Supports should be located at each corner of the house and at the intersection of walls at a distance of at least 2.5 m from each other.

At the first stage, it is necessary to make a competent marking of the site. On its territory it is necessary to designate the places where the pillars will be installed. This stage is decisive. The stability of the future foundation depends on how competently the basic calculations and markings are carried out.

- First you need to determine the type of soil that prevails in the place where the house will be built.

- Then you can proceed to the calculations. It is necessary to determine the weight of the structure. Of course, most likely it will not be possible to determine the exact number, but the approximate mass can be calculated based on the material that is planned to be used in the construction of a house or cottage. The figure that will be obtained during the calculation must be divided by the mass.

- The result is a figure that corresponds to the area of \u200b\u200bthe foundation. Now you can try to determine the number of pillars that will be needed during construction. For this, the area of \u200b\u200bthe foundation obtained earlier is divided by the area of \u200b\u200bthe support of one column. As a result, the figure is obtained, for the sake of which all calculations were carried out.

When marking up, it is worth considering a number of nuances, which include:

- the presence of a support at each corner of the future building;

- the presence of supports in those places where the walls intersect;

- the distance between the supports should not be less than 2.5 m.

Back to index

Land works: nuances

Columnar piles are driven to a depth of 1.5 m, the sand cushion must correspond to the distance from the ground to the grillage.

After the marking is completed, you can start land work. To begin with, it is worth taking care of removing the vegetation layer from the surface of the earth. All unnecessary items should be absent on it. This applies to stones, construction debris and so on.

In the event that trees grow on the territory, you will have to obtain an appropriate permit for their cutting. In the case of location near other structures, it is necessary to strictly stipulate the boundaries of the construction site in advance.

Next, you need to dig holes in the places where the pillars will be installed. Their depth should be slightly more than the value of soil freezing for these places. Additional centimeters will be needed to lay the sand cushion.

The width of the dug hole should clearly correspond to the thickness of the future wall. At the same time, do not forget that it is better to leave another 20 cm on each side. This will greatly simplify the procedure for installing the formwork, as well as the supports under it. Further, at the bottom of each pit, it is necessary to fill up a pillow, which consists of a mixture of sand and gravel. It must be carefully compacted. A layer of polyethylene or roofing material should be laid on the pillow.

Back to index

Formwork construction and reinforcing cage construction

A columnar foundation with a grillage must be installed below the freezing level of the soil to prevent frost heaving.

The formwork should be made from boards whose thickness exceeds 20 cm. It is the boards that are used, since they are easy to mount. Some use metal counterparts in construction, but this is much more expensive and less efficient. Boards are knocked down into shields. Boxes are knocked down from the received shields. As a result, formwork is obtained. The surface of the formwork must be moistened with water.

Thanks to this nuance, the formwork will be easier to mount. In addition, it will not absorb moisture from concrete, and this is a very important indicator.

Now you can proceed with the installation of the reinforcement cage. This is a very important stage, on which the strength of the future structure will directly depend. All rods are placed in the formwork. In this case, the distance between them and the walls of the formwork should not be less than 5 cm.

All longitudinal and transverse bars must be connected to each other.

This is done quite simply. The whole process can be done manually, but it is much easier to use a special gun for knitting reinforcement. The longitudinal reinforcement should protrude slightly above the formwork surface, since it will later need to be connected to the reinforced grillage frame. This whole structure is assembled on the ground, and only then placed in a pit.

Back to index

Foundation concreting

Concrete grade M 200 is suitable for concreting the foundation.

In the prepared formwork with reinforcement, you need to pour the solution. It can be poured in layers of several centimeters. It is extremely important that the solution is mixed. This can be done with a bayonet or vibrator. In this case, all excess air is removed from the concrete, which can lead to the formation of a porous structure.

So, after pouring the solution, it is worth waiting a few days until it hardens. At the same time, the formwork with the solution must be covered from bright sunlight. This is done in order to eliminate the possibility of evaporation of concrete milk, which allows the structure to remain solid and strong. After the formwork is removed, the concrete is still not fully cured. It will take much more time for it to fully harden.

Often, only 1 month is enough to complete the process. Despite this, work on the construction of the grillage can already begin.