The architectural forms of modern construction of a private house are infinitely diverse. In the past few decades, houses with several floors have been invariably popular in Russia. An obligatory attribute of such houses are interfloor stairs. If in Soviet times this design played an exclusively functional role, now it is a prominent, and sometimes the main, design element of the whole house.

Such interfloor stairs in a private house, as in the photo below, have practically gone down in history and remain only in long-built houses.

The main disadvantage of such a project is not so much appearance, How many high level hazards during its operation. The rapid pace of development of the construction industry allows you to choose inexpensive and safe options for interfloor stairs for a private house.

Types of interfloor stairs

Inside a private house, the following types of interfloor stairs can be used:

- modular;

- screw;

- marching;

- combined;

- straight;

- curvilinear;

- T- or U-shaped;

- compact.

Construction types

There is a division of interfloor stairs and the type of construction.

- bolt;

- on stringers;

- attic;

- on bowstrings;

- on the casing.

The choice of the type of staircase, the type of its design and the materials from which it will be made should be carried out at the design stage of the entire building. Even giving preference to the finished interfloor staircase, you should decide what functions, in addition to the main ones, it will perform. In addition, the size of the room where it will be installed also plays an important role in the choice. For example, a marching one takes up a lot of space, so it must be located in a large room, which often automatically leads it to the role of the main design element.

It is important to ensure that the stairs to be installed correspond to the dimensions of the room.

This requires a more responsible approach to the choice of both the appearance of the stairs and the method of its installation - whether it will be mounted by invited professionals or will be made and installed independently.

Homemade ladder

Professionals involved in the production and installation of stairs in private homes are inattentive to details and leave minor imperfections. Therefore, you can consider how to make an interfloor ladder with your own hands. In the absence of experience in the production of such structures, intricate options, such as spiral staircases, should not be considered. The easiest is to make it out of wood. In this case, possible errors and shortcomings can be easily corrected without significant costs. In addition, the tree allows you to choose any desired color and is lightweight.

Regardless of experience, you need to start manufacturing a structure with a project and calculations. The main emphasis in the design is on safety and comfort of use. Among the many factors to consider first of all:

- the size of the room and its height;

- maximum load;

- operating comfort.

Another important point of the project should be security. Modern requirements in this area provide for the presence of handrails and balusters for interfloor structures, and the latter must be located so that a child's head does not pass between them. Some individual stair designs suggest that parents of young children cover the railings with mesh or Plexiglas.

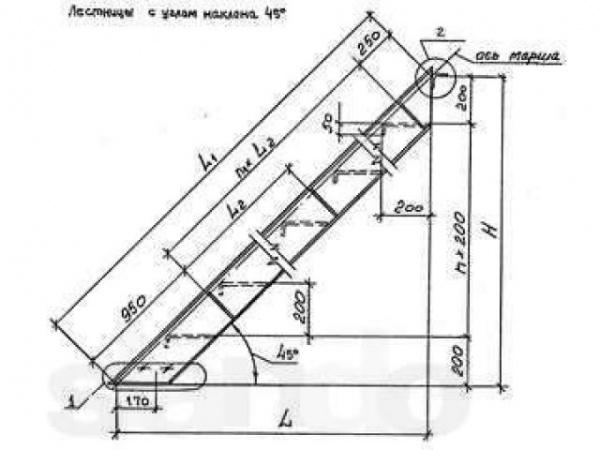

Important! The optimal angle of inclination of the interfloor stairs is 35-45 degrees. With a slope below 30 degrees, a large area is needed, and above 45 degrees, you will have to go down it backwards.

Designing a staircase is the most important stage in its production, which allows you to foresee all possible difficulties, avoid mistakes and waste of effort, time and money.

Material selection

For a wooden interfloor structure, planed hardwood or softwood is perfect. When buying materials, you should pay attention to:

- dryness of the material - the tree must be dry;

- wood color - there should be no stains;

- a minimum of large knots - the optimal diameter is 10 millimeters;

- lack of defects - chips and scuffs are unacceptable.

The choice of material will also be affected by the parameters of the stairs. Be sure to take into account the height and width of the steps. The ideal height is about 20 centimeters, the width is about 30 centimeters.

Project in numbers

One of the main points in the manufacture of an interfloor staircase with your own hands is the calculation. Even at the design stage, a design drawing is created. The calculation of an interfloor wooden staircase is the application of all data to an existing drawing. The first step is to take measurements. In the manufacture of a mid-flight staircase, the height of the room is first measured, then the length of the platform where it will be installed. The number of steps is calculated. To do this, the length along the floor must be divided by the width of the steps. The total width of the stairs should be calculated based on the size of the room and the personal desires of the owners of the house.

The next step is to determine the design size. To do this, you must select the size and height of the railings and balusters, if they are provided for by the project. After that, the calculation of the interfloor staircase should include data on the reliability and strength of the floor and ceilings in the places where the product will be installed.

Production process

After completing the calculations and strengthening the places where the staircase will be located, you can begin to produce the parts that make it up. Considering production using the example of a mid-flight staircase, the first thing to do is to make stringers - the details on which the steps themselves will be installed.

Important! Stringers must be cut perfectly correctly, it is best to do this according to a pre-made pattern.

The manufacture of steps involves careful grinding of these elements. This procedure is necessary for the safety of the operation of the stairs, and for its appearance. Railings and balusters are easiest to buy ready-made, their choice is very rich. It will not be difficult to make them yourself with the help of a special tool, if one is available.

Next comes the moment of direct installation of the stairs. First, a support pole is installed. Then load-bearing beams are placed, on which the position of the steps should be marked. After that, you can begin to fasten the stringers. The prepared structure is recommended to be processed with grinding tools in order to prepare for the installation of steps.

Before you begin to thoroughly fix the elements of the steps on the stringers, you need to try on and eliminate the existing shortcomings. After that, the structure is fully assembled. In order for the steps not to move during fastening, they must first be fixed with PVA glue or any other glue intended for wooden products. You can learn more about how an interfloor staircase is made by yourself by watching the video:

When the main frame of the stairs is ready, the safety elements are mounted. Balusters are installed first. In accordance with the requirements, you need to put two balusters on one step if there are children in the house. In other cases, one will be enough to support the railing. Next, the handrails themselves are mounted. The final fastening of the railing is made on the extreme racks of the stairs.

After that, the fully assembled staircase is processed with sandpaper and finally polished.

Staircase decor

When the finished staircase is fixed, fully assembled and sanded, it is recommended to treat the structure with decorative materials. First of all, you need to cover all accessible surfaces with a special stain that will protect the wood from the damaging effects of the environment. After a long drying, the ladder can be covered with several layers of varnish. A layer of special wax will complete the decorating treatment, a layer of which will allow you to maintain novelty and color for as long as possible. If the design of the entire room provides for painting the stairs in a certain color, then a layer of wax should be applied only after the paint has completely dried.

Upon completion of decorative processing, the design is ready for application and use for its intended purpose.

Having chosen the independent production of an interfloor wooden staircase, you need to carefully consider the details, carefully calculate all the stages of production and take all stages of production responsibly. A well-made staircase will be the pride of the one who made it and will serve all households for many years.

Today, one-story suburban construction can not be found often - houses are usually built in two or three floors. Moving between floors should be accessible and convenient for residents, no matter what age category they represent. Therefore, the construction of stairs requires special attention. The construction of the most ordinary staircase requires knowledge of regulatory information, accurate calculations, and an understanding of the mechanics of the step. Errors during construction can lead to a reduction in the service life, the occurrence of traumatic situations during movement.

Materials for the manufacture of stairs

The choice of materials for interfloor stairs in a private house today is quite wide and should be based on quality characteristics:

- strength,

- resistance to mechanical stress,

- ability to withstand exposure to high humidity or excessive dryness of air and temperature extremes.

No less valuable qualities of the material are the ease of care for it, the ability to clean using modern detergents. For the right choice, you will need to first study the advantages of the most popular materials.

wooden staircase

To date, the most commonly used wooden stairs in the house. The first question that worries future owners is whether it will creak during operation. There is no categorically unambiguous answer to the question. At certain moments, it happens that stairs made by well-known manufacturing companies and purchased for a rather large amount of money creak.

Experts advise considering the following points:

- any type of wood reacts in a certain way to increased humidity or vice versa to increased dryness, “painfully” endures temperature changes in the house and also reacts to other similar moments;

- when choosing a material for the manufacture of a flight of stairs, it should be remembered that different types wood, respectively, react differently to temperature, humidity, and the like, that is, it is impractical to combine, for example, oak and pine in one staircase;

- when choosing a tree for the manufacture of stairs, you need to pay attention to perfectly dried material, otherwise, after a short period of time, cracks and deflections may form on the steps;

- The last point that experts recommend paying attention to is care, wood is a rather whimsical material, so it needs high-quality and timely care, in particular, you can use varnish with a special wood-strengthening complex. According to fire safety standards, a ladder made of wood is recommended to be mounted to connect a maximum of two floors.

To maximize the life of a ladder made of wood, you should remember:

- in no case should a heating system be placed under it;

- under no circumstances should it be flooded with water.

The staircase in the design of the house is a bright and prominent element, so it should be treated as something important and valuable.

metal stairs

Another fairly popular material for the manufacture of stairs is metal. With today's development of technology, metal stairs can be made in a rather interesting way, they will fit perfectly into any modern design interior. The steps of metal stairs are made of steel or cast iron. You can also use stainless steel, which has a long service life, chrome-plated or painted steel, but, unfortunately, their service life will not be long. You can also find interfloor stairs made of anodized aluminum or brass.

The decoration of the stairs can be made according to your own sketch, if you wish - you can trust the imagination of interior designers. Metal is a very interesting material to work with. For example, using a powder coating, you can achieve the effect of a marble coating, or polish to a perfect shine, or make the surface chrome plated. In any case, the final look of the metal staircase will satisfy even the most demanding consumer.

stone stairs and ceramic

There is another type of stairs that are more practical to use and durable in terms of service life - these are ceramic or stone. Flights of stairs from such material were made in the days of ancient culture. In some historical places they can be observed even today. From this we can conclude that there is no demolition of such a building material. But, here, too, there is a drawback - a slippery surface, but modern developers have invented a special film with which it will not be difficult to eliminate this drawback.

Most often, granites or quartzites are used for the manufacture of stairs, which are distinguished by a particularly long service life. Products made of natural marble are very beautiful, but since it is a soft rock, after a few years traces of abrasion of the material will become noticeable on the surface of the steps. Not the worst option for stair material is concrete-based artificial stone, strong and durable.

glass staircase

The most creative type of stairs today are glass models. They look perfect in modern and high-tech styles, give the design of the room airiness, grace, sophistication. Glass for the manufacture of steps is used laminated or tempered, however, with strong impacts, scratches or cracks may appear on the surface.

Sometimes they resort to the use of acrylic glass, although it is particularly durable, but over time it tends to yellow, scratches become noticeable on its surface. Of the significant drawbacks of glass models, their rather high cost can be noted.

combined stairs

Some designers skillfully combine several building materials and get quite interesting views decoration of staircases. There can be many modifications. For example, a base made of metal with steps made of wood or another option would not look bad: lay stone steps on a wooden frame-base and finish the structure with metal, forged railings.

Interfloor stairs in your home - what designs are commonly used in a modern interior

spiral staircase

A spiral staircase is certainly a tempting idea, but this kind of design is rather impractical to use and far from safe. Most homeowners who have tried such stairs replace them with others that are less uncomfortable. Manufacturers, in turn, are trying to exclude the provision of services for the installation of screw openings from their price lists. In historical documents, spiral staircases are described as the most convenient lines for defense: being on it, one warrior could suppress the attacks of an unlimited number of opponents.

The case with staircases built spirally is quite different. They look luxurious and pompous. When planning a staircase of this type in your room, you should remember that its project must be planned simultaneously with the design of the entire room. Its installation in the constructed building is not possible.

It is also practiced to use spiral and spiral staircases as auxiliary ones, which are used to descend to the basement or rise to the attic. Such stairs are given a variety of shapes: round, rectangular, octagonal, square, etc.

In terms of materials, metal and wood, or a combination of a metal stud and wooden steps. The installation of such a ladder is justified if the diameter of the opening for installation is so small that it does not allow the use of other structures, but with a decrease in the opening, the steepness of the stairs will increase.

In any case, when choosing any option for erecting a staircase, the most important thing is to ensure that it is convenient and practical, and then beautiful. Do not forget that in the house, past the owners, there may be friends, relatives and children, whose behavior is quite difficult to predict.

marching stairs

Such designs can be found much more often than the above-described screw or spiral. They take up a lot of space, but at the same time they are practical and convenient. The design of marching stairs can be very diverse, the common thing in any of them is the presence of a continuous series of steps, which, in fact, represent a flight of stairs. The number of such marches and landings for each individual case is determined by calculation.

First calculate:

- whether the marching staircase will fit in a particular room,

- can it at the same time have a sufficient angle to the floor surface (ideally - 45 degrees),

- whether its width can meet the recommended standards.

When calculating a mid-flight ladder, you should remember the following rules:

- the climb will seem easy if the march consists of no more than 10 steps,

- if the height of the room requires 20 steps to climb, then it is better to divide them into two marches, and build a landing between them,

- in width, the landing should be equal to the march; in length, it should be a multiple of a person's step.

Depending on the distance between the floors and the area allotted for the construction of the stairs, the type of march is selected:

- a straight line representing a single span connecting two floors,

- rotary, consisting of several marches and intermediate platforms, allowing you to save space without changing the height of the steps.

Ladders are installed most often along the wall, pantries, niches, utility rooms are equipped under them. When choosing the best design option, you should not rely only on your preferences - you should take into account the features of the architectural solution of the house and the recommendations of specialists.

stairs on the rails - what is the reason for its attractiveness

The very name of this design indicates that during the construction, fastening bolts or pins, called bolts, are used. They are attached directly to the wall. The design is light and compact, it is ideal for rooms with a small area. Boltsovye stairs, as the most economical, are very popular with modern developers.

Although such a staircase looks light and airy, in fact, its safety margin is designed for a weight of about one and a half tons. The positive point is that such a staircase does not prevent the penetration of light into the room, which contributes to a visual increase in its dimensions.

Stringers or bowstrings are not used during the installation of such stairs, but the installation of railings or fences is mandatory.

Principles for choosing stairs for a private house

Before starting construction, you should get expert advice on where it is better to design a staircase. Next, you can begin to study the types of stairs and choose the most suitable one: bolt, spiral or mid-flight. You should think about the convenience and safety of the stairs.

It is recommended to get advice from design engineers regarding the arrangement of the stairwell, in each house its parameters are individual. Choosing a company that will manufacture stairs should be very serious, you should ask about the duration of its stay on the market, consumer reviews.

Security Criteria

Safety is one of the most important factors to consider when designing and building a staircase in a private home. To obtain an excellent result, you will need to observe the ratio of the height of the rise and the width of the steps (25-30 cm), it is especially important correct installation first and last.

Do not build stairs with inclined steps or use slippery materials for them. The distance between the balusters should be no more than 15 cm, especially if children live in the house. It is possible to build a staircase without railings if it is located between two walls, in all the rest - the installation of railings is mandatory, their height should be about 0.8 - 0.85 m.

When constructing a wooden interfloor staircase, the wood should be treated with special protective compounds - this will significantly increase the level of fire safety at home.

When designing a staircase, it should be taken into account that the recommended width of the flight of stairs is from 0.8 to 1.2 m, the angle of its rise should be close to 45 degrees. Each square meter of the step must withstand a load of 300 kg.

Installation of the structure must be carried out in compliance with all the rules and regulations of fastening. Experts warn that deviations from the requirements in favor of making the stairs more decorative should not be allowed.

If the house has more than one floor, then it must certainly have reliable and high-quality interfloor stairs. It depends on them how easy and simple the inhabitants of the house will go up to the upper floors or into the attic, move pieces of furniture and various things back and forth. Of course, you can purchase a folding or sliding structure with crossbars, but using such a product on an ongoing basis is not the best option. Therefore, any owner of his own house at some point begins to be interested in making interfloor stairs with his own hands.

Types of stairs and materials for their manufacture

When dividing stairs into types, they take into account their design features, appearance, materials used in construction and their combinations, as well as design compliance with a certain interior style. According to the design and installation technology, all interfloor options are divided into:

- direct (marching);

- curvilinear.

An interfloor mid-flight staircase is a solution when the steps are directed in a straight line with an approximate angle of inclination of horizontal plane at 45 degrees. Depending on the steepness, the height of the interfloor distance and the free area on the lower floor, the staircase structure may have an intermediate platform that provides a 90 or 180 degree rotation of the climbing person. Each march is a span filled with steps, the number of which should not exceed 15-18.

Spiral interfloor staircases in a private house are used in case of a shortage of space, as they take up really little space. The minimum allowable diameter of a curved structure is 1.3 meters, but as a standard they try to increase this distance to 2 meters. Regardless of the width of the steps planned in the calculation, their depth in the central part should fall in the range of 200-250 mm.

Another interfloor option is bolt stairs. They are alternately referred to as marching, then to screw. In fact, these structures got their name due to the “airy”, but strong connection of the steps to each other with special steel pins - bolts. Such fasteners are installed only on one side - facing the room. On the other hand, the installation is carried out directly to the wall. As for the configuration, it can be either straight, like marching solutions, or curved, close to the screw version.

Safety of interfloor stairs: the main values

The calculation of the interfloor staircase without fail accompanies the preparation of a construction project. Ideally, work on the construction of an interfloor structure is planned at the stage of creating a house. Then you can immediately orient yourself by the distribution of the load and provide for the strengthening of the foundation zones and the installation site bearing walls. But even if this did not happen immediately, then you can do the calculation later. In any case, when carrying out calculations, familiarization with regulatory recommendations and planned values will be required.

When you plan an interfloor staircase with your own hands, you will need to calculate and take into account in the project:

- Tilt angle. For a mid-flight staircase, an indicator of 45 degrees is recommended, for a spiral staircase it can be more.

- The width of the tread (the horizontal surface of the step) should not be less than 250-300 mm - the parameter approximately corresponds to the size of the foot of an adult man.

- The length of the step itself or the width of the march. Often a permissible minimum of 800 mm is used, but the most comfortable for use is a wooden interfloor staircase, in which this parameter is 1000 mm. The determining moment for this indicator will be the throughput of the structure: after all, if only one or two people climb it, then it is quite possible to get by with the minimum requirements in the calculations.

- Step height. The riser can be equal to 150 mm, but a slightly larger value is most convenient for lifting - 180 mm. It is not allowed to exceed the height of more than 200 mm, since such a design would be dangerous for the ascent and descent of a person.

- Distance between balusters. With a column thickness of 50 mm, the gap between them should be 100-150 mm. The calculation of this element is especially important for houses in which children live.

It is important to remember that when increasing the overall width of the flight of stairs, it is worth taking care of an additional level of security - adding a second railing or handrail that will run parallel to the first, but on the opposite side of the flight.

It is also believed that making small adjustments to the baseline can improve the ergonomics of an interfloor staircase. We are talking about doubling the height of the riser while increasing the width of the tread. But experiments of this kind must be carried out very carefully so that there is no critical excess of building standards.

There are also recommendations for the screw design. The distance of the support post from the edge of the stairs should exceed 1100 mm, but at the same time, if the parameter exceeded the value of 1500 mm, the width of the step in its narrow part should be 100 mm.

Installation of interfloor stairs

Interfloor metal stairs, as well as other complex designs require professionalism when creating. But for some options, most often from wooden materials, self-production is acceptable. After carrying out the design work, calculation and selection of materials, you can proceed to the installation and construction activities themselves. Once again, it is worth clarifying that interfloor stairs made of concrete should be mounted by a professional team - only screw solutions or marching straight wooden structures are assembled with their own hands.

Instructions for installing a wooden staircase consists of the following steps:

- Choosing a location for installing stairs.

- Calculation and design image of all structural elements, taking into account the type of the future product.

- Calculation of the amount required building material and his purchase. An interfloor staircase on a metal frame requires a special order of some parts, in particular a kosour.

- According to the calculations made, all elements are prepared for individual sizes. If there is a danger of making a mistake, it is better to trust this stage professional carpenters or craftsmen who constantly work with wood.

- Preparation of stringers and fasteners, their installation and approximate marking under the steps in compliance with the strict horizontality of the supporting surfaces.

- Step-by-step assembly of the march: fastening of risers, treads. It is very important to carefully connect all the elements, achieving maximum structural strength.

- Installation of an intermediate platform, for which lumber or a wooden shield is used.

- Strong fastening of the march to the floor and interfloor overlap using large bolts and anchors, as well as a cross beam.

- Installation of fences: installation of balusters, extreme and intermediate racks. As fastening materials, a system of grooved joints and metal studs are used. For the extreme racks, on which the main load falls when using the ladder, anchoring is used.

- Installation of railings for adults is carried out at the height recommended by SNiPs, but a second lower row for children is also possible - if necessary.

- Decoration of the finished work. To increase the external attractiveness, various linings, carved elements, and wooden decorations are used.

- At the last stage, interfloor wooden stairs are coated with impregnation, varnish or paint.

All works, regardless of their level of complexity, must be carried out at the highest quality level. After all, the safety of people when using the stairs depends on how the assembly and installation of the entire structure are carried out. The time spent on creating projects and schemes pays off with a sense of pride and joy for a job well done.

Country houses are increasingly being built on 2, 3 floors, which in itself implies the construction of stairs between floors (photo). With apparent external simplicity, these designs are important functional and decorative elements that do not tolerate negligence and amateur performance. There are clear laws that must be observed when building stairs in a private house:

1. It should be comfortable for all people living in the building, regardless of age and health status.

2. The staircase must comply with safety standards and at the same time fit into the design of the room.

Safety and convenience come first. To build even the simplest interfloor staircase in a house, you need to know the standards for this design, be able to correctly calculate it, while understanding and taking into account the mechanics of a person’s step. This will help to avoid traumatic situations and greatly extend the life of the stairs.

From what you can make an interfloor staircase with your own hands

Materials suitable for the construction of an interfloor staircase in a private house must comply with the following characteristics:

- be strong enough to easily cope with the load placed on them;

- have durability, because the stairs in any house are not built for a year or two;

- be resistant to fluctuations in humidity in the room and not be deformed from them;

— to be comfortable enough for cleaning with a vacuum cleaner and any other modern detergents.

The most popular and common materials for the construction of stairs are wood, metal and concrete. These materials are sometimes used solo, but more often they are combined (photo), achieving maximum strength and convenience of construction.

Wooden stairs

A wooden interfloor staircase (photo) is most often used in two-story buildings. This is required by fire safety standards: during a fire, people should be able to go down from the third and higher floors until the stairs burn out. No matter how much you want to make a wooden interfloor staircase in your three-story house, we strongly recommend that you resist this temptation in the name of the safety of your loved ones.

Another issue that worries the owners of private houses concerns the creak of wood. It cannot be 100% guaranteed that even the highest quality wooden staircase will not creak over time. Wood reacts to the humidity / dryness of the room, changing its volumes and, as a result, the density of adhesion between functional elements. Hence the creak.

To minimize this unpleasant effect, we advise you to choose one type of wood for the construction of stairs. In this case, the entire structure will respond equally to changing external conditions. The combination of different types of wood within the same staircase will lead to significant differences in their volume and a strong creak.

The second point that you need to consider if you decide to do everything yourself is the degree of drying of the source material for construction. The wood must be perfectly dry! Raw wood will begin to shrink over time and become severely deformed. Steps may bend or gaps may form in other structural elements.

Safety Compliance

In order for a hand-made wooden staircase to last for a long time, 2 conditions must be met:

1. Do not place heaters under or near it.

2. Protect the ladder from flooding with water.

Metal stairs

In a private house with your own hands you can do and metal structure(a photo). In this case, the following materials are used:

- thick stainless steel;

- cast iron;

- chrome steel (less durable);

- anodized aluminum or brass (used less frequently than other materials).

The metal has special advantages due to its ductility and the availability of various ways to process it. You can use this material in different ways in the interior. For example, using powder coating, you can achieve the effect of a marble coating. Chrome-plated surfaces also look very impressive. Especially in high-tech interiors.

If you want to do something similar with your own hands in your own home, but do not know how to properly apply all these possibilities of metal, you can resort to the services of a professional designer. An experienced specialist will tell you which staircase will best fit into the interior of your home.

Stone and concrete stairs

Stairs made of stone - expensive, but also the most reliable option. Mankind has been using them for thousands of years. Now such structures are also being built, as a rule, in large mansions and in a very expensive interior. The base of the stairs can be made of reinforced concrete (photo), but the cladding is already made of stone.

The advantages of such structures lie in their exceptional durability and beauty. But there is also a drawback. If the steps were faced with marble or artificial stone marbled, they will be slippery. To avoid injury during use, we recommend that you cover the steps with a special anti-slip film with your own hands.

Combined stairs

Ladders made of different materials are the most practical and durable. The base is best made of concrete or metal, and the steps and handrails are made of wood that is warm and comfortable for the feet and hands.

Interfloor staircase designs

In a private house with your own hands, you can make several types of stairs. The most common are marching (photo).

Spiral or spiral staircases look very impressive (photo).

But no matter how beautiful they look in the interior, in practice they turn out to be very inconvenient.

For many categories of users - the elderly, sick people, children, pregnant women - it is extremely difficult to use a spiral or spiral staircase. We advise you to take this into account if you want to make one of these designs in your home.

Accounts are important!

If you decide to make an interfloor staircase in your house with your own hands, you should always start with calculations. There are clear standards of convenience and safety that must be observed. They have been thought out by mankind for a long time, tested by many generations of users, so it is useless to argue with these norms. In the name of your own safety and comfort, it is better to take them on faith and strictly observe them during the construction of your stairs.

The first thing to focus on is the ease of ascent and descent. It is important to observe the correct height and width of the steps, their number and the steepness of the staircase itself. The optimal length of the flight of stairs is no more than 10 steps. If there are more of them, the person experiences fatigue during the ascent.

Too steep stairs are also unacceptable. You can still go up on it, but it is almost impossible to go down! This is an almost impossible task not only for children and people with disabilities, but also for quite healthy and strong residents of the house. So this should be avoided in every possible way, otherwise living in the building will become simply unbearable. The ideal angle of inclination of the stairs is 45 degrees.

To make it flatter and reduce the number of steps, two- or three-flight designs are made. Between marches, it is desirable to leave enough spacious landings so that a person going upstairs can rest on them and take a breath (photo). One march should include 8-10 steps. You should not make the Potemkin Stairs in your home.

Width and height of steps

The dimensions of the steps and the width of the staircase itself are very important. In width, it should be at least 80-90 cm. It is better if it is 1.2-1.5 m. But here you have to proceed from the parameters of the room itself. Carefully calculate which staircase you can afford to the maximum (!) And try to make it as spacious as possible. In the future, you will appreciate this convenience.

The second most important question concerns the width and height of the steps. It is clearly calculated according to the length of a person's leg and the mechanics of his step. The width of the tread (photo) should be 27 cm. This is the average length of a person's leg. If the steps are narrower, you will have to climb / descend them sideways or along the wall. This is not only inconvenient, but also extremely unsafe.

The optimal height of the steps is 14-20 cm. Not lower and not higher! If the steps are lower, a person will have to take many more steps, and this is extremely tiring. Higher steps will be a real test for all residents of the house, which is also unacceptable.

Opening under the stairs

And the last point that you should pay attention to is the size of the opening in which the staircase itself will be located. The opening should be spacious enough to accommodate the most convenient and comfortable staircase for people living in the building (photo). This point must be taken into account at the design stage of the house.

If the opening was not made according to calculation and turned out to be too narrow, it will have to be expanded. It is very difficult to do this with concrete floors, not only because of the strength of the material itself, but also because there is a high risk of breaking the reinforcement. And yet it will have to be done, because otherwise you will not be able to properly use your stairs.

Before you build anything - a whole house or a staircase in it - always carefully calculate everything in advance. With regard to interfloor stairs, this is especially important. And do not try to save money in this matter! Quality is the main condition for your safety.

Inhabitants apartment buildings climb the stairs from the front door to their apartment. But in private houses, stairs are used not only for their intended purpose, but also as an element of decor, as well as a place for storage. It doesn’t matter what size the room is, the variety of designs allows you to choose an interfloor staircase based on the architectural features of the house.

Staircase inside the house to the second floor: device features

Having built a house or cottage, it is necessary to install a staircase to the second floor, but it must meet certain standards, consist of fire-resistant and durable materials.

In addition to the aesthetic component, you need to take care and not forget about safety, for example:

- Stairs should be well lit;

- If one person lives in the house, then the width of the stairs must be at least 0.8 meters;

- The weight on the supporting part must be at least 100 kg, and on the chassis not less than 180 kg;

- The installation of railings is provided for stairs that have three or more steps and their height should not be less than 0.9 meters;

- According to the safety rules, the steps must have a certain slope, for residential premises it is at least 38 degrees, for attics and attics from 63 to 74 degrees, for single-family buildings at least 45 degrees;

- All parts of the structure must be treated with non-combustible substances or consist of refractory materials;

- An important factor is the height of the steps, the difference between them must be at least 5 mm, the width is from 220 mm, the height is from 130 to 200 mm, and the number of steps in one span must be odd.

If the stairs between the second and first floors do not meet the above requirements, then it is unacceptable for operation according to the rules of SNiP.

Internal stairs: convenience and elegance

It is no longer a novelty for us to see high-rise apartments and a private house on several floors. This is a design solution that allows you to get maximum living space with a small area. To take advantage upper floors, you need to use a solid ladder, which you can make yourself according to your idea or buy it ready-made in a hardware store. It all depends on the financial and technical features. Making your own stairs is not difficult.

Most often in private houses or apartments they use mid-flight stairs, which are divided into the following types:

- Stairs on stringers (made of metal or wood. They consist of beams separately connected to the base in turn).

- Design on strings (the design is complex, the steps are fixed on the inside of the beam).

- Stairs on the bolts (made of metal and wood, structural details are bolted together).

- Spiral staircase (made of wood, as well as metal, consists of handrails, steps and racks).

On kosoura - this type of stairs is considered the safest and most popular.

Such a staircase can be installed in any room, since its size can be different, however, like the execution, it all depends on the style of the interior.

It can be made with or without risers. The method of fixing the steps directly depends on the number of beams that are attached to the base. The beam can be one or two.

Kosours can be:

- Screw;

- broken lines;

- Direct.

On bowstrings, such stairs emphasize the architectural component of the house and show the individuality of the owner's thinking. This staircase looks great in combination with classic style, has a complex structure. Steps are attached with inside beams.

Bolts - this type of stairs is able to withstand a lot of weight. The beam is fixed to the walls or floor using metal rods. Steps in this design can be of any size and shape. Spiral staircase - spiral staircases save space, which is why they are popular. Consist of steps, racks and handrails, this design is attached to the wall.

Types of spiral stairs:

- Square;

- round;

- Octagonal.

Especially popular and customized design in modern style design use curvilinear stairs. Also, stairs can be closed with an approach or open without it. All types of stairs are relevant in their own way, it all depends on the needs and imagination.

Finished interfloor stairs

During construction high-rise building or dachas implies the use of stairs between the first and second floor. Self-manufacturing will require certain calculations, experience with metal and wood, not every person has such skills. A finished interfloor staircase is an excellent way out in a situation where there is no time to manufacture the structure yourself. In construction stores, a huge selection of stairs for every taste and from any materials. Buying a finished structure, it remains only to assemble it according to the drawing.

You can buy a ladder in several ways:

- Online store. Through the Internet, you can buy an economy class staircase, you only have to choose the color and material.

- In a hardware store, you can more scrupulously approach the choice of the design you need. A wider choice will be presented to you as finished products, and under the order according to your sizes.

- The last option is the most expensive. If a custom design is required, then individual project, which will be designed according to the features of the house.

Before you buy a ladder, decide on the installation location. It is necessary to determine the dimensions of the stairs - this is the most important task. If you can’t take measurements yourself, the help of a specialist from a ladder manufacturing company will be most welcome. The material from which the staircase will be made can be the most diverse, it all depends on financial capabilities and imagination.

Wood remains the most inexpensive and popular, as well as durable material.

Under the order, you can make, for example, an iron staircase that will be decorated with brick slips. The installation and type of stairs can be different, as there are a lot of options. If a we are talking about self installation, you do not need to purchase a staircase of complex shapes. Also, upon additional request, if necessary, manufacturers can supply the ladder with a lifting mechanism.

It is better to purchase a staircase from a trusted and experienced manufacturer, as an incorrectly manufactured design can lead to injury inside your home.

Do-it-yourself interfloor stairs in a private house

In order to understand how to make an internal staircase, you need to understand what it consists of.

Components of the stairs:

- Steps and support for steps. The step consists of 2 parts - the vertical one is called the riser, the horizontal one is the tread. Supports are divided into 2 types. The first, the bowstring, holds the step from the side of the transverse cut, and the stringer supports the step from below.

- Railing.

- Balusters - the support of the railing.

- Rack - an element of a spiral staircase.

- Boltsy - fastening for steps and beams to the wall.

Taking into account the safety requirements, determining the dimensions, collecting the necessary tools and materials, you can proceed to the construction of the stairs according to the drawing.

Correct measurements and then calculations are essential. After all, the successful outcome of the construction depends on it.

A comfortable staircase is one that has the ratio of rising and moving forward. When designing, you need to remember that the height of the steps of one march should be the same. Double the sum of the height of the riser and step is equal to the length of a human step (this is about 66 cm). When calculating the slope of the steps, measure the distance from the plane of the step to the ceiling (it must be at least 2 meters). Of course, each type of staircase has its own construction procedure.

Production of details of interfloor stairs in a private house

After the calculation and drawing up of the drawing, the dimensions are transferred to the material. The most difficult thing is to accurately make stringers, you need to accurately cut them into the material while maintaining accuracy.

In the manufacture of steps, the edges of the treads must be perfectly rounded.

If a closed staircase is planned, the risers must also be processed. Balusters and handrails can be bought at a hardware store, they are sold already with ready-made fasteners. If the house has Small child for safety reasons, two balusters are installed on one step. Next, you just have to assemble the structure starting with the stringers, then the risers are attached, then the steps are mounted, then the balusters and railings are installed. The finished staircase is varnished and after complete drying is ready for use.

How to make an interfloor staircase with your own hands (video)

So, open, front internal stairs - can be made for every taste. Variants of curved stairs are also possible. The main thing is to think over their drawings.