What kind of foundation is needed for a house made of aerated concrete? There is no single correct answer. Almost any of the possible ones will be a great start for the presented type of building. It is worth noting that the design of the base for a wooden or brick building is selected quickly, however, new materials have their own standards and requirements.

Attention! The foundation project for an aerated concrete house requires deep thinking and knowledge of some tricks that will help speed up the pouring process and create a structure that can withstand almost any load.

When designing a foundation for a house, many make a fatal mistake - counting that for a light material, a massive foundation is not required. The strip foundation for a house made of aerated concrete must have a calculated strength and depth, otherwise, soon, the structure of the house will crack. The main task of the concrete substrate during construction is to create conditions under which the entire pressure force will diverge evenly without peak areas.

Strip foundation for aerated concrete house

The main problem in the construction of the construction of supports for a house made of aerated concrete is the buoyancy force. It is this force that is balanced by buildings that are built from heavier materials. To solve the problem, you need to understand what width will be ideal. Concrete underlay cottage from aerated concrete can be shallow, but it is worth paying great attention to exactly how it will be designed.

Important! With a shallow base form, it is necessary to use a sand cushion. It is this pillow that contributes to better stability of the foundation even with deep freezing of the soil.

It is worth noting that the most suitable option is the pile construction of a support for a house made of aerated concrete, as in the video:

The presented form of the foundation of the house, due to additional piles, is able to keep the base of the building from deformation on almost any soil or soil. Thanks to the piles, the deepening of which, as a rule, reaches 1 meter, they transfer the load to the soil and counteract the pushing forces.

Foundation for a two-story house made of aerated concrete

In order to construct a foundation with your own hands for a two-story aerated concrete house, it is necessary to take into account all the important aspects of the building. Among all, the main ones are:

- wall mass and pressure force per linear meter of aerated concrete base;

- the mass of floors, which will exert additional pressure on the base of the building;

- roof mass as additional mass.

During construction two-story house, the question remains important - what size of the foundation for a house made of light material is needed. Professional builders who build such buildings recommend using a structure that is at least 10 centimeters wider than the building block at the top and 15-20 wider at the bottom. It is this wedge-shaped design that will maximize the prevention of the "moving out" of the house on the ground. Also, when using such a base, you should pay attention to the substrate, which, as a rule, made exclusively from sand.

In general, the calculation of the base for a house made of aerated concrete can be carried out using an ordinary calculator for calculating the tape base for construction.

Foundation slab for aerated concrete house

This type of foundation is characterized by the fact that concrete is poured directly under the entire surface of the structure. There are some positive sides and negative when using such a building foundation. Among the positives, one can distinguish:

- ease of pouring concrete mixture immediately at the construction site;

- using less reinforcement to strengthen the base;

- the foundation itself, if desired, can serve as an excellent floor inside the built house;

- distributing the mass of the entire house onto the slab reduces the buoyancy force acting on the house.

Among the negative points, the use of this type of foundation, it can be noted:

- high costs for concrete for the preparation of concrete mix;

- the need to level a larger surface horizontally, which is possible only with the help of special equipment;

- to fill such a foundation, you need to pick up a flat area or make a large number of earthworks to level the site for pouring;

- this type of foundation requires long-term miscalculations for plumbing, gas and waste fittings;

- the need for careful selection of soil to accommodate such a base structure;

- prolonged drying of the surface with a monolithic type of filling will not allow construction, immediately after organizational work.

Attention: like tape construction, the presented view can “lean” on piles, which will increase the allowable load directly on the foundation.

Much attention should be paid directly to the characteristics of the soil under the future building. The disadvantages of choosing such a foundation include a shallow occurrence: at the same time, high-rise buildings without additional fortifications can “float” after a while due to soil erosion. Also, the presented type of pouring the base is not suitable for those regions where the freezing depth is higher than the mark of 1 m.

Aerated concrete is very widely used for the construction of buildings and structures. This material quickly gained popularity due to its low price, low weight, ease of construction and low thermal conductivity, which means that the house will be warm.

The low weight of the material will help save on the foundation, good insulation saves money on wall insulation, so the real savings increase compared to the nominal.

But such material is fragile, does not work well for bending. Therefore, it is necessary to choose a foundation that will take into account all the shortcomings, as well as at least partially level them.

Types of foundations that are used for the construction of buildings from gas blocks:

- tape;

- columnar;

- monolithic;

- reinforced concrete slab.

In order to determine the type of foundation, it is necessary to perform a load calculation, find out the characteristics of the soil, the depth of soil freezing in a given region, and establish the seismic situation in the construction area.

To correctly calculate the foundation, you will need the help of a qualified specialist. The online calculator presented below will help determine the needs for materials, even for those who are not well versed in construction.

The strip foundation is reinforced concrete structure in the form of a tape with a closed contour. It is arranged under the load-bearing walls of the building. This foundation for an aerated concrete house is best suited, and it is he who is most often used.

Sequence of the strip base device

- Axes are split.

- A trench of the required depth is dug. Aerated concrete is a lightweight material and here you can save money, but you need to take into account the depth of soil freezing. How deep the trench will be - will determine the calculation.

- A sand cushion is made in the trench, then drainage material is poured.

- Formwork installation, it is better to use panel formwork.

- A reinforcing cage is placed in the formwork.

- It is poured with concrete mortar with parallel compaction with a vibrator.

If there are not very large loads on the base, and the soil is strong enough and not loose, then the foundation for a house made of aerated concrete can be installed columnar. This type of foundation is very economical.

Pillars are installed only at the corners of the structure, at the intersection bearing walls and in high traffic areas. What will be the pitch of the pillars depends on the design of the structure, but not wider than 2.5 meters.

Necessary tools and materials

Column base mounting technology

- Markup in progress. Pegs are installed on it.

- Wells of the required depth are pulled out.

- Poles are installed. They can be brick or reinforced concrete. If the load is low, then piles of metal pipes may come up.

- The tops of the pillars will be united with a grillage.

The most reliable foundation for a house made of aerated concrete is monolithic. Aerated concrete is brittle and does not work well for bending, therefore, in the event of subsidence of the soil, the structure may crack and the integrity of the structure may be violated.

Such a basis is established in the case of:

- high occurrence ground water;

- the presence of unreliable soils prone to landslides or subsidence;

- construction in a seismically active zone;

- uneven relief.

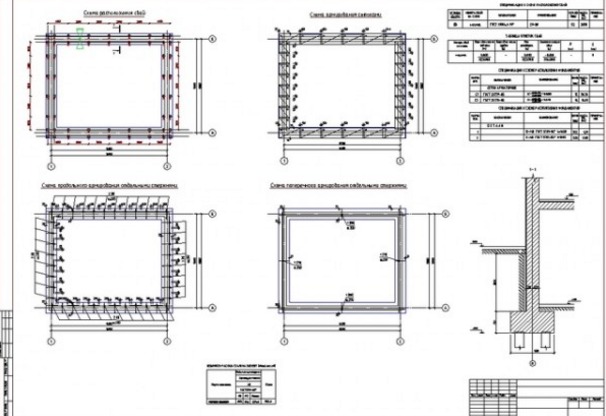

Monolithic base installation technology

- Site marking is in progress.

- The pit is digging.

- Formwork is installed. The load on it will be serious, so it is necessary to securely fix the walls of the structure.

- A reinforcing mesh of 12 mm rods is laid. It is knitted directly at the place of installation.

- Poured concrete mix in separate layers, while immediately compacted with vibrators.

- After the concrete has hardened, the formwork is removed, after which they begin to erect walls or columns.

- This foundation requires significant financial investment, but it will forever protect against problems associated with adverse effects during the operation of the building, because. this is the strongest and most reliable foundation.

Reinforced concrete slab. Such a foundation for a house made of aerated concrete is also very reliable. This plate is arranged over the entire area of \u200b\u200bthe building. Based on the calculations, the optimal height of the plate is 400 mm. Its underground part is 100 mm, and the aboveground part is 300 mm.

With this design of the base, there is no need to lay it to the freezing depth, because. he is not afraid of frost. In case of ground displacement, the foundation slab, together with the building that is built on it, will be displaced. Therefore, it will not suffer any destruction.

Due to the large area of the base of the foundation, the specific load on the surface is minimized.

Reinforced concrete slab device technology

- Earthworks are being carried out.

- Formwork is installed.

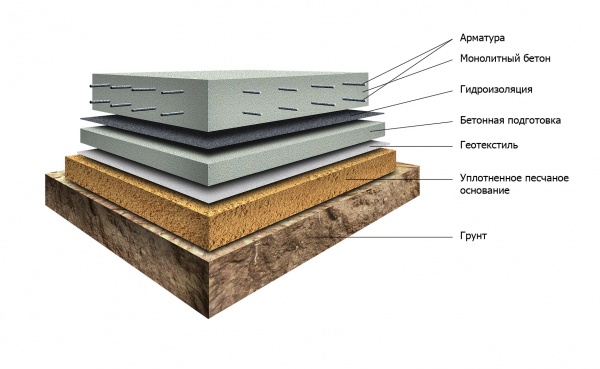

- The bottom of the pit is rammed, then a pillow is laid, after which waterproofing is performed in two layers.

- Reinforcing meshes and frames are knitted on site.

- With the help of a concrete pump, a concrete solution is supplied, in small layers of 150 mm, and it is immediately compacted with the help of vibrators.

- After sufficient hydration of reinforced concrete, the formwork is removed, after which subsequent work is carried out.

Possible mistakes

During the construction process, it is important to avoid mistakes that can lead to the destruction of the structure. Sometimes they specifically change the dimensions of the structure, or the parameters of the section of elements, in order to save money. But this is fraught with consequences.

The main mistakes made by builders:

- foundation depth error;

- incorrect calculation of parameters;

- wrong choice of fittings or violations in the manufacture of reinforcing products;

- error when choosing a brand of solution;

- the wrong choice of base is the main mistake.

Many factors need to be taken into account. Initially, it is necessary to pay attention to the characteristics of the soil. If the soils are reliable, a more economical type of foundation can be used. If the soil is unstable, a more solid supporting structure will need to be erected. Unreliable soil leads to deformation of the base.

What can be the deformation:

- the shift occurs in the presence of loose soils, when one side sags;

- bending is the most common deformation. May occur in case of uneven shrinkage;

- roll can occur during the construction of a high-rise building;

- gerekos occurs if the house sags unevenly;

- horizontal displacement, most often found in basement walls.

In order to determine the supporting structure, you need to study their types and characteristics; establish the reliability of soils, as well as correctly perform all calculations. Having provided all the nuances, you can choose a base that will be reliable enough, while not overpaying.

The foundation is one of the main structures. He perceives the load from the entire building, then transfers it to the ground. Therefore, it is important to choose the right base, under such a modern and popular view construction, like a house made of aerated concrete.

For the construction of a house from aerated concrete blocks, it is advisable to construct a tape-type foundation base with a slight penetration into the ground. The relatively small weight of aerated concrete structures does not require the creation of a massive foundation. Such construction is recommended on dry sandy soils.

The procedure for building a foundation for a house made of aerated concrete

The algorithm for constructing a foundation for an aerated concrete house begins with its calculation. The planned foundation must support the expected weight of the house, supplemented by possible snow or wind loads. After calculating the project and creating a drawing, the parameters of the future foundation are transferred to the site, while special attention is paid to ensuring that the corners of your future foundation remain perfectly straight. For this, measurements are used not only of the sides of the structure, but also of its diagonals.

Earthwork stage

The contours of the future foundation foundation are marked on the terrain with pegs, between which a strong cord is stretched. After checking the diagonals and calculating right angles using the Pythagorean theorem, earthworks begin.

In the event that there is a layer of black soil on your site, it must be removed and deepened into the clay base by about 30 centimeters. The basis for the foundation of a house made of aerated concrete should be two pillows - sand - up to 20 centimeters thick and a crushed stone pillow about 10 centimeters thick.

A trench for the future foundation of an aerated concrete house can be dug both manually and using earthmoving equipment. It is preferable to use a ditch digger or an excavator with a narrowed bucket.

In some cases, wooden formwork is installed along the walls of the trench. However, when good quality the surrounding soil can be dispensed with without it.

Installation of a reinforcing structure

Mandatory element when creating strip foundation is the installation of a reinforcing structure. It is created from reinforcing bars, which are tied together at the intersections with knitting wire.

When preparing the reinforcing cage, welding work is not carried out. It takes about 30 centimeters of knitting wire to connect each intersection node.

A ring is formed from the binding wire at the intersection of the reinforcing bars.

Which is then tightened with a hook - bent at an angle and a pointed piece of reinforcing bar.

The first reinforcing layer is installed at a height of about twenty centimeters from the bottom surface of the future foundation.

To fix the distance of the first layer of the reinforcing frame from the bottom surface, pieces of concrete or bricks are used, on which the structure is laid.

Additionally, the joints of the reinforcing frame at the corners of our structure are carefully fixed.

It is possible to link the structure on the ground. After fixing it with a knitting wire, it is lowered into the prepared trench.

Through each meter, pieces of reinforcing bar can be driven into the bottom of the trenches. They will become anchor points for fixing the reinforcing structure. In addition, the upper edges of the bars can be drawn along the horizon and they will serve as beacons that determine the upper level of the future foundation base for the aerated concrete house.

Pouring with concrete mortar

Usually, concrete pouring of the created formwork with a reinforcing structure takes place in one stage. To do this, you must first determine the total volume of concrete that will be required to fill the entire tape of the foundation.

In the event that it is impossible to fill the entire foundation in one stage, then it must be poured in layers, along the entire perimeter, and not separately for each wall of the base.

When dry, the concrete mortar requires maintenance. So, on hot days, it must be regularly spilled with water. It is possible to cover the poured concrete with a layer of wood shavings in order to prevent excessive evaporation of moisture.

Concrete can be watered with an ordinary garden hose. Also, when pouring concrete, it is possible to carry out its “ironization” - to scatter a layer of pure cement on its surface through a sieve. This technique will create an additional layer of waterproofing of the foundation base.

Carrying out horizontal waterproofing

At the foundation base under the aerated concrete house, it is necessary to carry out horizontal waterproofing work to protect the concrete and prevent moisture from entering the house.

To do this, you can use sheet waterproofing material, which is applied to the concrete surface in a hot way using a blowtorch.

Before laying sheet waterproofing material - the concrete surface can be smeared with bituminous mastic, which will serve as an additional insulating layer and a means of gluing the sheet to the surface concrete base.

When cutting sheet waterproofing material, it must be ensured that its width is greater than the width of the concrete base and it forms a kind of "umbrella".

The plinth of an aerated concrete building can be formed from concrete blocks or moisture-resistant bricks. It is possible to cast a block of concrete, but such work will require the creation of additional wooden formwork, which will inevitably affect the cost.

On both sides: from the inside and outside on the plinth, it is necessary to carry out vertical waterproofing. To do this, you can use bituminous mastic, which is applied in several layers.

Bituminous mastic can be applied with a roller or brush.

For additional thermal insulation, a layer of foamed polymer material must be glued onto the bituminous mastic. For warm regions, it is enough to apply a sheet about three centimeters thick.

Video - instructions for building a foundation for a house made of aerated concrete

The desire of people to live in a comfortable home makes them invent, apply best materials, facilitating and qualitatively improving the construction of the building. Aerated concrete is a multi-purpose material that is used in construction. The use of high-quality aerated concrete ensures durability and cost-effectiveness. The question of choosing a foundation for such a house is always relevant.

Aerated concrete is a porous stone made from water, quartz sand, cement and gas-forming materials. Special molds are filled with the prepared mixture, in which, thanks to gas generators, the mixture increases in volume. After hardening, it is cut into the required dimensions and subjected to hardening.

Formwork is laid on top of the pillars and the base cushion is poured. The frame of such a base should consist of two rows of reinforcement. Height, width, cross section are calculated by specialists. Column Foundation- good money savings, but not suitable for buildings with or basements.

pile

Recently, the use of construction is gaining popularity. By design, it is similar to a columnar, but instead of pillars, piles or supports are used. Unlike pillars, piles are narrower, longer and are divided into the following types:

- screw;

- bored;

- driven.

- iron pipes with blades at the bottom for easy entry into the ground. The shallow installation method allows you to screw them in with your own hands, for greater depth you will need to use a special device. Inside the piles are filled with concrete.

Wells are prepared for bored piles. A reinforcing cage is inserted inside the pipes and concreted. In practice, screw and bored piles are more often used. The tops of the installed piles are combined with a supporting structure that allows masonry. unstable to ground movement, therefore, this type can only be used on dense soils.

Professional design drawing.

Professional design drawing. Carrying out correct calculations requires knowledge of some parameters:

- the degree of constant load;

- structure weight.

Intermittent load - seasonal precipitation and its effect on the building. The permanent load consists of the mass of the building, the furnishings and the people who will be in the building.

Having found out the load calculations, the calculations of a single plate are carried out. Based on practice, the height of the slab should be at least 40 cm, while its underground part is 10 cm, the rest is aboveground. Having calculated the thickness and total area of \u200b\u200bthe base, you can approach the calculation of the amount of building material.

Foundation selection criteria

The types of foundations do not change, they are traditional. Which type to choose is a difficult question. The following criteria will help you make the right choice:

- Soil characteristics. It’s impossible to evaluate the properties by eye, and it’s dangerous - you need an accurate result, because under the layer of sand there may be a layer of peat, and this is a problem for the house. First, it is necessary to carry out geological activities on land plot. You'll have to turn to the experts. They will determine the type of soil, soil freezing, groundwater depth, assess the danger of soil advancement, issue a resolution and give an explanation for the construction.

- The relief of the site leaves its mark on the choice of foundation. They want to have a house in good beautiful place, overlooking the water. Slopes, cliffs, ravines, elevation changes are likely to advance the soil. A heavy structure will exacerbate the situation, so it is worth considering everything before preparing a place for construction.

- The dimensions of the structure, types of material should be taken into account when preparing for construction in the first place. The height of the building, the thickness of the walls, whether you need a basement or a basement - everything is taken into account in the design documents, and in the group with geology it determines the characteristics of the zero cycle.

By comparing all three criteria, knowing all the information about the foundations, you can come to a competent decision on the construction of a certain type of foundation.