Difficulties in moving people handicapped- a problem that they face every day, not only at home, but also on the street. After all, for a person who moves in a wheelchair, many places are simply not accessible, especially those that can only be reached with the help of stairs. These buildings, along with the degrees, are equipped with ramps.

Depending on your individual circumstances, your disability and need for access may be temporary or permanent, either way we have a solution to suit your budget and Nottingham property design. A particular ramp installation is a more permanent fixture for your home, so design permission may be requested to make this a permanent disabled access. As with most of our services, we will visit your home to assess your individual needs for your particular wheelchair ramp.

What is a ramp?

The ramp is an indispensable structure in our time for driving with a slope for strollers, bicycles, wheelchairs and other vehicles. Most often it duplicates stairs. The ramp is installed at the entrance to the room or on the flight of stairs. Its main purpose is that it combines different in height horizontal planes technical purpose: for the disabled or transport.

After we look at the slope of the ramp, the area to cover and suitability for your home, we will make sure to go the extra mile before we start installing your wheelchair ramp. If required with any particular ramp, we will place handrails on the side of the ramp to provide additional user safety. We have completed many jobs in and around Nottingham for wheelchair specific ramps, some of which can be seen in our gallery.

Design requirements according to GOST

If in some cases you only require a temporary wheelchair access solution or prefer a metal option for concrete, then we can quote for delivery and installation. We have worked with leading providers in the trafficking industry for many years and are able to survey and install secure semi-permanent metal ramps for almost any property. As with concrete ramps, these metal options come with handrails to make your home easier to access.

Ramp device - basic requirements:

The angle of inclination of the ramp should be minimal so that a disabled person in a chair can climb it independently.

The surface should be non-slippery, straight, without any irregularities. Nothing should interfere with the movement.

The design is a concrete flight of stairs, but instead of steps it has a flat plane of descent. Unlike a ladder, its slope should not exceed 10%, and a 9% lifting plane is already a deviation from the norm, since a person with disabilities cannot climb it without someone's help.

Metal handicapped access is a popular choice for most of our clients in and around Nottingham as it is ideal for people who are in a temporary accommodation situation as these ramps leave very little permanent ground impact but give you peace of mind and you need to access the house in a wheelchair or with a walking aid. These types of ramps can be installed in a short amount of time and are a very economical wheelchair solution for your home.

What are the types?

First of all, let's define what types of ramps are. Depending on the material used:

metal;

concrete;

wooden.

There are also ramps:

Stationary;

Folding;

Removable.

Stationary installed at the entrance to the building. They don't clean up. Flip-ups are used when space is limited and lowered when needed. They are fixed on the wall of the passage. They are often installed in houses where the installation of a stationary one will interfere with the free passage of other residents. Removable ones are installed temporarily, to overcome an obstacle at a particular moment. They, in turn, also come in various types:

1. Sliding telescopic - two ramps that extend in length and do not take up much space when assembled.

2. Roll ramps are an option for those who have very little space. Thanks to a special frame, they are twisted like a carpet.

3. Ramps - a folding model that is used to overcome thresholds and other small hills.

Boat Rockets, whether you're building a ramp for personal use, or in the case of the Game and Inland Fisheries Department, public use, many of the things to consider are the same. Some of these are criteria, permits, design, construction methods and materials, and the type and size of boats to be launched.

The first thing to consider when considering a ramp is the type and size of boats to be launched and retrieved. Obviously, site selection and design of a launch platform for a canoe or carriage in shallow water will be very different from site selection and design of a launch ramp for launching large trolley boats in tidal water. If you're designing a ramp for your personal use, it's fairly easy to choose a design that will accommodate boats and towed vehicles that you own or may own.

More ramps can be classified into:

monolithic;

with wall support;

with full support on the ground or bedding.

Ramp device - how to do it yourself?

Definition of design parameters

Concrete ramp is one of the most stable types. They are single-march (for one span) or multi-march (with intermediate platforms). It depends on the lift height. The maximum length of one strip should not exceed 9 meters, so one long plane cannot be made over a long distance. It is also taken into account that the maximum height of the march is 80 cm. Based on this, when calculating the dimensions of the ramp, it is necessary to take into account the sites at the beginning, at the end of the ramp, as well as intermediate platforms. When constructing a ramp, it is important to know that nothing should interfere with the rise, for example, doors. The landings must be of sufficient size so that there is enough space for the stroller to turn freely.

Choosing a design that will suit multiple boaters or the general public is trickier. When selecting and evaluating a site as a potential boat site, consideration should be given to site accessibility, proximity to other boat ramps, water depths, silt levels, and usable land area.

One of the most obvious considerations for site selection is its proximity to existing roads and other ramps. Road construction and road maintenance, so the closer the site is to a maintained road, the better. Those thinking of building their own ramp would need to consider using existing ramps if available, and even the cost of maintenance costs with the owner.

The minimum width of the ramp plane should be 1 m, this is if one-way traffic is provided, and, accordingly, 2 m, if it is two-way. The law also provides for the mandatory installation of bumpers on the ramp so that the wheels of the stroller do NOT jump from the surface. Their minimum height is 5 cm. For safety and ease of movement with a ramp, it is equipped with railings on both sides. Handrails should be located along the entire length, their height should take into account the needs of children and adults. Therefore, the railing is placed at a height of 50 cm for a child and, accordingly, 70, 90 cm for an adult.

Water depth should be at least three feet at the end of the ramp during medium low water, although four feet is more desirable. If trailers will be used to launch and retrieve boats, consider extending the ramp to a depth of five feet or installing a riparp at the end of the ramp. If the end of the ramp is not secured, the wash of the support created when the power is loaded will destroy the opening at the end of the ramp, causing it to fall out violently and may undermine the end of the ramp. If the trailer wheels then back away from the ramp end that has a lug, the trailer can hang on the end of the ramp, which can cause damage to the trailer as the wheels are pulled back onto the ramp.

Ramp device - calculation

Before starting work, you need to prepare, make all the necessary calculations and measurements, that is, draw up a project. According to the regulations, the height of the ramp should be related to the length in the calculation of 1:12. This means that for the construction of a structure with a height of 1 meter, it is necessary to make it 12 meters long, with a height of 1.2 meters - 15 meters. However, according to the norms, it is forbidden to do this, so you need to divide it into 2 marches of the same length - 7.5 meters each, the platform between the marches will be at a height of 0.6 meters (h1 / 2 = 1.2 / 2)

Another consideration for water depth is the possibility that the water depth will not remain constant. River channels move from side to side and can undermine the end of your ramp, causing the gap to stop. The same happens with channels in intertidal areas, especially when the site is at a point that compresses a large bay. Quite the opposite applies to sites at the back of small bays, nearby streams, or on long sandy beaches. These areas are often areas of active deposition where silt or sand can coat your ramp.

The size of the site between marches is 2 m2. Based on this, you need l1 17 m2 (15 m and 2 m platform).

V1 \u003d 1/10 s \u003d 1/10 17 m2 \u003d 1.7 cubic meters.

V2 \u003d h1 * l1 \u003d 1, 2 * 15 \u003d 18 m2 * ½ brick thickness (0.125 m) \u003d 2.225 cubic meters.

m = 2, 25: 0.002 = 1125 pieces.

We also determine the volume of used backfill (9 m3) and the required length of reinforcement rods (243 running meters):

area - s;

ramp height - h1;

platform height - h2;

plate length - l1;

volume of concrete - v1;

wall volume - v2;

the number of bricks is n.

Dredging and maintenance of deep water dredging is costly, can adversely affect the environment, and is often complicated because suitable locations must be located to accommodate the dredged material. If dredging can be avoided, do it!

The size of the ramp and parking lot depends on the intended use. If no more than 80 launches per day are expected, one launch strip will be sufficient. More than 80 launches justify additional launch lanes and parking spaces. When deciding how many parking spaces can be provided on a piece of land, remember that a trailer parking space must be at least 10 feet wide and 40 feet long with suitable maneuver room to line up and enter and get out of the parking space.

Ramp device - work sequence

Ramp reinforcement.

Step 1. We make markings for construction with cords and pegs. This takes into account the internal width of the future design.

Step 2. We fill the foundation under the walls.

Step 3. We carry out stretching and setting the slope.

Step 4: Posting brick walls. After that, we wait about a month.

Step 5. We fall asleep the distance between the walls.

Step 6. It is necessary to make a protective layer between falling asleep and concrete (polyethylene is often used).

Step 7. We reinforce the structure.

Step 8. Making a flanging.

Step 9. We make concreting. It is better to fill in the brand not lower than M300 from the bottom up. Since the top layer will dry quickly, it is smeared with water so that everything dries evenly. If cracks appear after it has completely dried, they can be fixed with a cement screed.

Step 9. We do the installation of the railing.

Step 10 We cover the structure with bridge or other material.

A warning regarding boat ramp size should not underestimate the land required. Remember that large areas of wetlands cannot be disturbed. Also, a 30ft or 40ft turning radius and a staging area is needed at the head of the ramp, and no matter how big you make public facilities, there will still be a calm sunny warm day off when that won't be enough. If at all possible, reserve areas for parking expansion and overflow.

We determine the design parameters

Once you've laid out the site for the ramp, it's enough to know how you want to build it to prepare a sketch. The next step is to apply for the required permits. The Virginia Marine Resources Commission, Corps of Engineers, State Water Control Board, and local wetland board may require a permit. Some localities also require a local building permit.

The device of the ramp is a necessary thing. Not only people with disabilities move along the ramp, but also people with wheelchairs. This will at least make it easier to visit a particular house. Before pouring the structure of the structure, it is necessary to decide which place fit better Total. Then do the calculations. If you have chosen a ramp made of concrete, then the above instructions will help you calculate everything.

The design of the site, ramp and pier will have a significant impact on construction and maintenance costs, as well as the usability of the facilities. Find the time it takes to deliver a durable, economical and functional design.

Special requirements for ramp handrails

Provide enough room to bring the towing vehicle and trailer in good alignment with the ramp, and enough space for the staging area to get the boat ready for launch. If possible, place the dock on the same side of the ramp as the driver. This will give the driver a better idea when they get back to the trailer next to the pier. To reduce congestion, one-way traffic is desirable in the parking lot and intermediate platform. Corner parking is usually easier to execute than other parking plans and reduces the required parking lane width.

A ramp is an inclined platform that connects two horizontal planes of different heights. Provides for wheeled transport the ability to move from one plane to another. IN Everyday life most often used is a ramp for wheelchairs, wheelchairs or children. It is the most common means that allows a person with limited motor abilities to overcome stairs, thresholds and other hills. You can install a ramp on the street, in entrances, subways and other public places.

Ramp slope standards

Parking spaces and road signs should be clearly marked to reduce traffic congestion and maximize the efficiency of the available parking space. The 1% slope at the parking lot and staging area helps prevent water pollution in these areas, but causes slow runoff that reduces erosion on untreated surfaces. The slope should be directed away from the ramp if possible to prevent gravel, sand, etc. from washing on the ramp. If two launch lanes need to be built, one strait between the lanes can serve both lanes and reduce costs, and also ensures that one boater cannot tie both lanes at the same time.

What ramps are. Types of structures and device

The most common types of ramps are:

Stationary

Stationary ramps are fixed structures that are designed to operate for a long time. They are usually installed outside the building. As a rule, they are two strips of a metal channel laid parallel to each other and equipped with handrails. Can also be made from concrete.

A line should be painted to the center of the ramp to help boaters stay on their side of the ramp. If not, the traction wheels of the towing vehicle can rotate and dig into surfaces as the trailer and boat climb up the ramp. 16 foot wide ramps are preferred by the general public, although many existing 12 foot ramps have proven satisfactory in low usage areas. Ramps located in flowing rivers should enter the river at an angle downstream to reduce side impact on the boat as it is placed on or off the trailer.

Folding ramps for wheelchairs

A folding ramp for wheelchairs is a subspecies of stationary products that can “recline”, freeing up a passage or flight of stairs. Usually they are used in entrances, private houses and other places with limited space, where a non-removable model would interfere with the free movement of people.

Ramp device

The design is attached to the wall or railing running along the stairs, with the help of hinges, heck and other locks. To lower or raise the stroller, it is enough to release the latch and lay the ramp on the flight of stairs.

In addition, an angled ramp generally accumulates less silt after a period of high water. If it is necessary to cut a river to the bank, set the slopes back as far as possible to reduce the amount of still water trapped in the cut during flooding, thereby reducing the amount of silt deposited on the ramp. Provide stabilized ditches on each side of the ramp to handle runoff during heavy rains.

If a pier is needed to assist in launching and retrieving boats, paying close attention to the small details of pier design can save you a lot of headaches and maintenance costs. While berths can be made from materials other than wood, only wood will be discussed here. Remember that a design using standard lumber lengths will be more economical.

Video: folding ramp at the entrance

Removable ramps

Removable ramps are distinguished by their mobility and flexibility in operation. Due small size, folding design and lightweight materials are easily transported in prams or wheelchairs. There are three categories according to the type of ramp device:

- sliding telescopic;

- ramps - ramps for thresholds;

- roll ramps.

Telescopic ramp

The telescopic ramp consists of two ramps that can be moved apart, increasing their length by 2 or more times. In the assembled state, the product takes up a minimum of space. It is very convenient for overcoming parapets, stairs, lifting strollers into the car and other purposes.

The working surface is covered with anti-slip material to prevent the stroller from rolling or is made of embossed metal.

Models differ from each other in the maximum length of the ramps, load capacity and width of the rails. So, when folded, the sliding ramp can withstand up to 400 kg.

Ramp - ramp for rapids

The wheelchair ramp is relatively small and is designed to overcome thresholds, curbs and other small obstacles. The folding ramp is lightweight in design and quick to install.

Roll ramp

The roll ramp has a high-tech frame that can be rolled up like a rug. In the folded state, such a product practically does not take up space. In a house where there is Small child, can be used as a ramp for prams.

Video: roll ramps in action

Parameters and dimensions of the ramp for wheelchairs

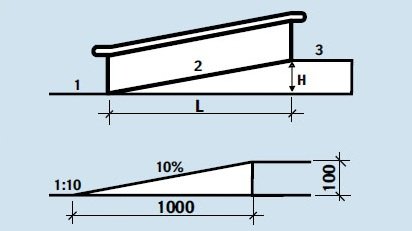

The main parameter of the ramp for the disabled is the slope of the working plane. It is measured as a percentage and is the ratio of the height (H) that it allows you to climb to the length of its horizontal projection (L).

If we take L = 1000 mm, H = 100 mm, then the slope of the ramp will be 10%.

The working surface of the product on which the stroller moves is called a march. The length of the march is another important size of the ramp.

According to the current GOST standards and the requirements of SNiP, the value of H should not be more than 80 cm when moving in a straight line (L) per meter. That is, 8% is the maximum ramp slope for wheelchairs. The exception is those cases when the rise does not exceed 20 cm. Then it is possible to increase the angle of inclination up to 10%. In other cases, for descent or ascent, people with disabilities require outside help.

Depending on the weight, dimensions and dimensions of the wheelbase of the stroller, the total width of the ramp for the disabled and its ramps is selected. The guide must freely fit the wheel of the vehicle. Designs with a single working surface have increased rigidity and load capacity.

Ramp design: SNiP norms and GOST requirements

When designing a ramp, it is extremely important to comply with the standards, norms of SNiP 35-01-2001 and take into account the requirements of GOST R 51261-99, in order to subsequently avoid problems with paperwork for the product.

- Be sure to have a horizontal platform before lifting. It should have dimensions that will make it possible to drive up to the ramps and stop, that is, no less than the dimensions of the stroller. The same platform is needed at the end of the descent so that a person has the opportunity to free his hands for any action.

- The width of the ramp for one-way traffic should be at least 90 cm. For two-way traffic - at least 1.8 m. handrail in the middle.

- If the ramp consists of several parts, for example, it is installed on a staircase with two spans, it is necessary to have intermediate platforms, the dimensions of which will make it possible to deploy the stroller. The depth of the platform should be at least one and a half meters, and the width should be equal to twice the width of the march.

Special requirements for ramp handrails:

- railings for ramps are mandatory if the lift height is more than 150 mm or the length is 1.8 m;

- must be located on both sides and be longer than the ramp itself by at least 30 cm;

- the diameter of the handrails can vary from 30 to 50 mm;

- the handrail of the wheelchair ramp must be round and form a continuous line along the entire length of the product;

- it is recommended to make a double handrail with heights of 60 cm and 80 cm.

- along the edges of the structure, there must be a side, the height of which is not less than 5 cm. It is necessary so that the wheels of the wheelchair do not accidentally slip off.

Remember that a ramp installed in violation of the norms can be dangerous both for the disabled person himself and for those around him.

How to make a ramp with your own hands

Ramps are needed not only for people with physical disabilities, but also for mothers who live in multi-storey buildings and walk with a stroller through the streets. In any case, in order to move freely with a stroller, you can make a ramp with your own hands.

metal ramp

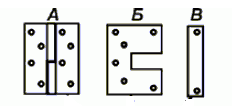

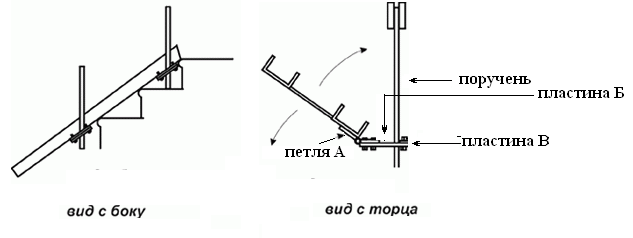

We will make a folding metal ramp for the stairs, which can be installed in the entrance, on the porch or any other place. For this we need:

The hinge is attached to the bottom of the ramp with countersunk bolts. The extension plate is the same width as the hinge and must be long enough to allow the structure to be leaned against the railing. The dimensions of the recess in the extension plate must be larger than the cross section of the stair railing.

A general view of the structure is shown in the ramp drawing:

Channel strips are fastened at a distance equal to the distance between the wheels of the stroller. At the same time, the fastening spacers should be located as close as possible to the risers of the stairs so that the person carrying the stroller does not trip over them. This design is attached to the railing with hinges, extension plates and fasteners.

To fix the folding ramp on the railing of the stairs, a loop is made for a chain or lock. If the product is fixed on the wall, as an alternative, you can install a latch that will hold the ramp. This uncomplicated device perfectly copes with its task.

DIY wooden ramp

A similar wheelchair ramp, but a little more complex, the material for which is wood. Designed for stairs with a railing on both sides or a railing and a wall. The device is perfect for installation in the entrance.

The folding ramp is made in the form of two wings, fastened with hinges to the railing of the stairs. The ramps are made of wooden boards, the size of which depends on the length of the stairs and the dimensions of the stroller. The width of the wings is such that when lowered, there is a small gap between them, which will make it possible for a person carrying a stroller to pass.

In the raised state, both wings are attached to the railing with locks. If the reverse side of the ramp is finished in an appropriate way, then in the folded form it will look like a staircase railing. The tree can be varnished, but it must be remembered that the work surface should not be slippery.

How to make a concrete ramp

The most reliable of all types of structures and the most durable. However, it is quite difficult to design and make a concrete ramp with your own hands. The construction of the product has several stages:

- Make a recess at the edge of the ramp where it will be thinnest. When pouring concrete, this will increase the thickness and prevent cracking or chipping of the edges of the structure. Ideally, make a deepening over the entire area.

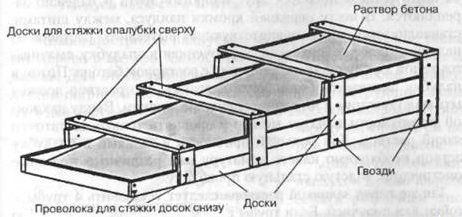

- Preparation of formwork for the construction of curbs. Creation of a sand and gravel cushion in the formwork, reinforcement and pouring with concrete. The result is two load-bearing curbs that define the limits of our design.

Such curbs act as stiffeners and prevent the structure from creeping to the sides. Sometimes, you can do without them. In this case, make a formwork for the entire ramp and immediately go to step "3".

- A sand and gravel cushion is again formed between the curbs: first, sand is filled and compacted, then gravel is added and it is compacted again. The thickness of the layer depends on the height of the structure at a given point. When creating a pillow, you must leave about 10 cm for reinforcement.

- The reinforcing cage is installed and concrete is poured. It is recommended to use concrete grade not lower than M300.

You can use the design only after the solution has completely hardened.

To avoid cracking of concrete, it is necessary that its upper and lower layers harden evenly. To do this, the already dried top layer is poured with water and covered with polyethylene. If the surface is still cracked, it is necessary to seal the cracks with a cement screed.