With the current level of technological progress, you can find many products where paint or enamel is used. Despite the fact that the meanings of "paint" and "enamel" are very close in meaning, there is still a difference.

If you look at Wikipedia and find information about alkyd enamel, then we will see that it has great weather resistance and shows itself well in resistance to detergents.

Alkyd or oil paints can be used to paint bathroom walls if they have been previously painted with alkyd or oil, or if the situation calls for it, otherwise latex products are beautiful paints. Latex paints come in any color you desire. Be sure to prime the walls prior to painting, fill in cracks or holes, press primer, and then paint to ensure the best possible finish.

Difficult Paints to Apply It may be shocking to many who use white primers, but grays are much better undercoats for hard-to-paint colors like reds and yellows. People who love red often don't necessarily enjoy the painting experience because it doesn't hide wall imperfections very well and requires at least three coats of paint to appear solid on the wall. This is because pigments such as magenta or yellow are bluer than blue pigments.

And if the surface is prepared for painting, having previously primed it, and then applied two layers of alkyd enamel, then it will retain its properties for four years or more. The main component of enamel is alkyd resin.

Kinds

![]() As for the types of alkyd enamel, there are a huge number of them. For example, the most versatile paint PF-115.

As for the types of alkyd enamel, there are a huge number of them. For example, the most versatile paint PF-115.

As a result, they require a different color to allow these pure pigments to have depth, otherwise light will shine through them, revealing the surface of the wall behind. Hence, we see poor coloration. This has been fixed in the last few years with primers that are dyed according to the chosen color to help enhance his clear coat. This, however, can be costly as the primer requires many shades. Usage gray color behind the pure color reduces the amount of light passing through the pure layer.

Why PF? The answer lies in the composition. It is made on the basis of pentaphthalic varnish. For this reason, it is also called pentaphthalic. There are other enamels from the PF category, but they have not gained wide popularity among ordinary consumers.

For example:

- PF-167;

- PF-266;

- PF-189;

- PF-123.

This is a small example regarding alkyd enamels.

In our opinion, this translates as a color with greater depth. The depth of gray should match the brightness or darkness of the color chosen for the wall. For example, a pale yellow should have a very light gray tone, while a dark red would use an equally deep gray.

Create your own stencils Add a pop of color to any room with this new decorative frame. Cutting your own stencils is an easy and rewarding creative task. Here's how you can do it: You'll need a smooth, clean surface that you can cut into, such as cardboard or a cutting mat, utility knife, anti-stain marker, non-absorbent spray adhesive, and mylar. When you have all these tools, you just need your design. Since Mylar is a translucent plastic paper, it can be laid over images and then traced onto the Mylar surface.

Application area

As for the scope of alkyd enamels, it is quite extensive.

As for the scope of alkyd enamels, it is quite extensive.

For example, take the most common and versatile type of this product PF-115.

This enamel paint a wide variety of surfaces:

Once the design is complete, move the Mylar sheet with its design to the cutting board. It's easier to keep mylar in place if you spray it from behind with a non-permanent spray and then secure it to the cut surface. Use a knife cutter to cut along your design to completion. Place the stencil on the surface you wish to paint on and apply the paints of your choice on top. Keep moving the stencil, adding spray adhesive to the back every now and then.

There are many great paints for your home and I have many favorites from different companies when it comes to painting your walls. On the left you'll see my first two favorite furniture paints are Benjamin Moore Advance and Sherwin Williams Proclassic, both of which are alkyd enamel paints on water based. Alkyds dry resins and are used in oil paints, but now synthetic variants are also used in water-based enamel paints. The important thing is that the enamel gives you a really heavy finish, which means that if you press it with your fingernail after a week or two, cure it, feel it to the touch, and not be pliable like other latex paints.

- tree;

- concrete;

- metal.

You can add an infinite number of materials to this list, because it is universal. But enamel called PF-67 is made by the manufacturer for only one purpose: painting ship hulls.

Its secret lies in the fact that it is incredibly resistant to physical influences and temperature extremes. The range of temperature values at which it does not lose its properties is from minus 50 to plus 60 degrees Celsius.

The nice thing about the Ben Moore and Sherwin Williams formulas is they are readily available from local distributors in any color. They are a bit more expensive than a regular quart of home improvement store paint, but they are well worth it. Both of these formulas require you to coat your furniture first, but water-based paints are so pure it's very easy. I love this paint for European or Cottage style finishes on furniture like drawers, chests of drawers, sideboards, etc. - this is very frustrating. I hope this answers your question Barbara, for your wardrobe, any of these three options will be great!

There is also an enamel called PF-1115. It is used to paint the decks of ships. It is excellently suited for this particular role due to the fact that it is extremely wear-resistant and has low heat absorption. Manufacturers produce it in only two colors: gray and dark gray.

At home, this paint can be used to cover the floor. For these purposes, PF-233 paint has been specially developed. They call it "Enamel for the floor" .

At home, this paint can be used to cover the floor. For these purposes, PF-233 paint has been specially developed. They call it "Enamel for the floor" .

Types of exterior paints for metal

There are a few tools you'll need to run: dab cloth, screwdriver, medium sanding wedge, bonding primer, enamel paint in a color of choice, 2" brush with a quality angle, water proof paint protector.

First of all, before you start, remove all hardware. If your part is in good condition, you can skip the sanding step or use a power sander and go straight to loading your part. You don't have to sweep away all the varnish and go down to the raw wood, just give it a good 5 to 10 minutes of sanding with a sanding wedge and then wipe off any debris with a soft cloth. Don't worry - a little glue for cutting. If your piece suffers from holes or dents, you can use wood filler to cover or fill in those unsightly spots.

The most interesting and perhaps offensive is that this enamel is produced only in “red” color or similar shades.

Enamel PF-266 has the same indications for use. But for painting metal structures in the open air, PF-1189 paint was developed. Usually she is painted with metal beams at construction sites, hangars, fences.

This is a cosmetic problem that is easily solved with wood filler, which allows you to repair scratches, dents, scars, and fill holes in wood furniture before you start painting it. If you choose new handles, they will often fit right into the old holes, but many modern pulls are a different size than the old ones. Wood filler is also the best choice to get started with new equipment.

If you want to keep your paint job going, using a good bonding primer is key. If you are using a spray form instead of a formula brush, be sure to work in a well-ventilated area and dispose of your jars according to local waste disposal regulations.

There is also glyptal enamel. We need such a paint for a specialized application and it is very rare to see it on the shelf in a store. She paints parts of electrical machines and the like.

It is mainly used as an insulating paint coating. Its distinguishing feature is that it dries at an elevated temperature above room temperature. The scope of these paints is huge.

A spray nozzle, available in most paint departments, will also promote more even coverage and also prevent finger spasms! Once the primer is completely dry, set aside any drips or residue and wipe off the piece with a soft cloth. Two thin strands should work if you're working with lighter shades of paint, sometimes a third light coat is needed if you're painting your piece navy, taupe or black.

Allow 6 to 8 hours drying between coats. A high quality angled brush is also important. The last thing you want to do is pull loose paint out of the paint, which happens with cheaper brushes, so don't worry about those. The angled brush also helps to get into grooves and crevices better, plus with a steady hand it cuts straight lines very well. This is for an eight year old room, so this shade of pale turquoise with original brass charms would be a gorgeous addition to her space.

Vehicle painting

If you touch on the painting of vehicles, then alkyd car enamels are mainly used.

If you touch on the painting of vehicles, then alkyd car enamels are mainly used.

Since the advent of nitrocellulose-based synthetic paints, the quality of car paint has improved significantly.

Benefits of Alkyd Coating

With enamel paints, it is not always necessary to use a protectant because enamel paint has a harder finish than regular latex paints. However, for a high use surface like a coffee table or the top of this chest of drawers and an extra layer of protection will help protect the paint.

Do not use oil based polyurethane, it will turn yellow or yellow over time. Reconnect your equipment when you paint is completely cured. With enamel paints it usually takes 3 to 5 days so be patient. This may sound time consuming and time consuming, but remember that a quick spray and protector are the quickest steps, it is the repair and paint processes that take the most time. With a little patience, you will achieve a perfectly painted piece with a smooth finish that will last for years to come.

The amount of solvent, as a rule, in such paints is large, and, due to this, they lie well and smoothly on the surface.

Well, in order to somehow speed up the drying process, accelerators are added to them, with the help of which the solvent evaporation process becomes several times faster.

Good to know: car painting is done in three layers. Only under this condition, you can achieve a good result.

Whether or not a color can be marked by the quality of the artists depends on a number of factors. The most important factor is the amount of pigments. In the "Artist" quality is a lot of pigment, so the consumer has intense colors. The second factor with the quality of the artists is the extensive color palette with colors including exclusive pigments. Finally, subtlety is important. The ingredients in the paint should be distributed as carefully as possible. This dispersion is carried out on a three-way roller. The base materials, which have already been distributed during pre-mixing, are passed over the roller several times until the ink has the desired degree of fineness.

The disadvantage of car enamels is that they dry out for a long time, and if the gloss has been lost due to mechanical stress, then it is almost impossible to return it.

But here the advantages more than cover the disadvantages. These include:

- good quality coating;

- excellent gloss;

- do not crack during use.

For household purposes

The variety and color range of such paints is so great that there are enamels specifically for painting batteries and radiators.

The variety and color range of such paints is so great that there are enamels specifically for painting batteries and radiators.

From a technical point of view, the difference lies in the binder. In the case of an alkyd paint, the binder is an alkyd resin dissolved in a turpentine substitute. When used, this results in the following differences. When using pure alkyd paint, the smear is partially lost during drying by evaporation of the turpentine substitute.

- This leaves less time for wet moisture to be applied.

- Alkyd paints require solvents to dilute and clean up the color.

A distinctive feature of this product is that it is heat resistant and will not crack when heated.

But in the composition of other enamels, special chemical substances. For example, to protect against fungus, in conditions of high humidity, or mold. I would also like to note that in the composition of such paints there is also a filler. This role can be played by both granite chips and marble, or sand.

Alkyd enamels are distinguished by these advantages

Commercially available substrates are already pre-treated with a universal primer. This is a good universal primer based on pure acrylate. When preparing open woven malt, it is advisable to apply a layer of ammonia acrylic binder. In this way, the meshes of the fabric are closed so that the Gesso does not penetrate the fabric into the back.

Production of alkyd and acrylic compounds

When cobra is diluted with water, universal prep substrates are the right choice. When not using water, can also be applied to mint fabrics prepared in the traditional way with an oil primer. For open woven malchust, it is recommended to apply a layer of ammonia acrylic binder. Not unless the paper is fully prepared. The oil is absorbed by the paper so that the pigments lose their binding. This may cause cracks. The gesso seen on the back is technically not a problem.

Just do not think that we will find some graininess in the enamel due to these additives, because the grinding of the filling substance is so fine that it cannot be noticed with the naked eye.

Minuses

The disadvantage of such paints can be considered their toxicity..

The disadvantage of such paints can be considered their toxicity..

They are characterized by a sharp and pungent odor that does not disappear for quite a long time.

If you need to paint in an enclosed space, then you need to take care of good ventilation. It is important for the employee to wear a mask, gloves, goggles, and a protective suit.

To work with alkyd enamel indoors, the artist must have:

- respirator;

- gloves;

- work clothes;

- protective glasses.

Due to the toxicity of the enamel components, it is highly recommended not to neglect safety precautions..

Marking

Not every person knows what kind of paint he needs and with what marking.

For example, the figure tells us about the characteristics of enamel:

- alkyd primer - 0;

- can be used for outdoor work - 1;

- only for internal works — 2;

- enamel is used for conservation work - 3;

- waterproof enamel - 4;

- for special purposes - 5;

- oil and petrol resistant - 6;

- suitable for aggressive environments - 7;

- heat-resistant - 8;

- for electrical insulation or wiring - 9.

As a rule, according to statistics, sales of first category enamel and primer show the highest rates. Accordingly, each group has glossy, matte and semi-gloss enamels available.

How and what to paint

As for the methods of applying enamel, everything will depend on our choice and surface. In most cases, enamel is applied with a brush, roller or spray gun.

As for the methods of applying enamel, everything will depend on our choice and surface. In most cases, enamel is applied with a brush, roller or spray gun.

Of course, each of the methods is good and at the same time has its drawbacks. For example, using a brush, we get a thicker layer and our enameled surface will be more dense and durable.

And if you use a paint roller, then we will significantly reduce material consumption, but in return we will get a problem with painting corners and other hard-to-reach places.

A spray gun can be used to quickly and easily apply paint, but handling requires some skill.

To obtain a good result, painting must be carried out in several layers. As a rule, at least two. If we need to save paint, then , it can be diluted with a solvent by 10%.

And if we need to paint a metal surface, then alkyd-urethane enamel is best suited for these purposes. Coating with such enamel will give the metal long-term protection from external influences of aggressive environments.

Manufacturer's choice

Despite the fact that the modern paint and varnish industry has stepped forward significantly, both domestic and foreign, the buyer prefers a foreign manufacturer.

Despite the fact that the modern paint and varnish industry has stepped forward significantly, both domestic and foreign, the buyer prefers a foreign manufacturer.

The reason for this is both the marketing move of foreign products and the fact that foreign manufacturers pay much more attention to innovative technologies in the manufacture of enamels, and besides, they produce their products using high-quality equipment and materials.

But the domestic manufacturer is more focused on universal brands of enamel and their cost. But you can not completely neglect the domestic manufacturer.

For example, alkyd enamel "Pentaclid" has good performance in all respects. It differs from most enamels in the absence of a strong pungent odor, and its drying time is much faster. It is excellent for painting wood, concrete and metal products.

If such enamel is applied on a previously primed surface and in two layers, then it will retain its protective properties for at least four years, in moderate cold. And if you touch on indoor work, then it will not lose its properties for six years or more.

It can also be applied wet on wet. And on the seventh day, our coating will completely polymerize and become hard. The film of this paint is quite elastic, which means it will not crack over time due to temperature changes and mechanical stress.

Watch the video which explains characteristics alkyd enamels:

There are a lot of alkyd enamels. This paint and varnish covering differs in universality, resistance to attrition, brightness of flowers. It can be used both for interior and exterior work, and due to the fact that alkyd enamel paint can be glossy, matte, and semi-gloss, its scope is almost limitless.

The composition of alkyd enamels and their properties

Alkyd enamels are made on the basis of alkyd varnish and various solvents with filler. In addition, they include coloring pigments that give the coating a certain color. Sometimes the manufacturer may include a variety of additives in the combination, for example, antiseptics that protect the surface to be painted from mold and fungal infections. The main solvent for alkyd enamels is white spirit. By the way, this is what you need to use if the paint has thickened. And sand, granite or marble chips and other materials with the same properties usually act as fillers. Do not confuse fillers for paint coatings with traditional sand and crumbs - their grinding is much finer and in their structure these materials are more like flour.

The most important component of alkyd enamels is alkyd varnish, which is of two types: pentaphthalic and glyptal. Most often, in the manufacture of paints, pentaphthalic varnish is used, which is a thick solution of resin in a solvent with the addition of vegetable oils, rosin and glycerin. The finished varnish is later mixed with a solvent to form an alkyd enamel.

Features of alkyd enamels

Among the features of alkyd enamels are their high elasticity and durability. Such coatings dry quickly enough, which allows them to be used indoors without much concern. In addition, such paints do not turn yellow when dried and do not lose their color, do not shrink.

They are also suitable for outdoor work, because they have high weather resistance - snow, rain, temperature changes are not terrible for alkyd enamels.

This type of coating perfectly protects against corrosion various metal surfaces (doors, windows, radiators, furniture, etc.), it is also able to withstand wet cleaning with conventional detergents and can be used in bathrooms, saunas and swimming pools.

Classification of alkyd enamels

Depending on the classification, alkyd enamels have different properties, methods and applications. Each brand has its own alphanumeric code, which allows you to determine whether the enamel belongs to one category or another. For example, alkyd enamel PF-120 matte white is deciphered as follows: PF - pentaphthalic (these letters indicate the substance that is used in the paint as a base); the number 1 indicates that the enamel can be used for outdoor work, and the number 20 is the catalog number.

In addition to unity, other numbers can be found on alkyd enamels: for example, the number " 0 » denotes an alkyd primer enamel, i.e. a coating intended for priming surfaces;

2 - enamel for indoor use (heated and unheated);

3 - conservation paints, that is, such paints and varnishes that are intended for temporary sealing of any equipment;

4 - waterproof paints;

5 - special paints with special characteristics (repelling rodents, glowing in the dark, etc.);

6 - oil and petrol resistant enamels;

7 - paints capable of withstanding chemical attack;

8 - heat-resistant paints;

9 - electrically conductive and electrically insulating paints.

Alkyd enamel GF-230

In this case, GF is glyptal. Such paint is intended only for interior work on painting ceilings and walls. It cannot be used for painting floors, since it does not withstand physical impacts well. Before you start using the enamel, it must be diluted to the desired consistency with white spirit or turpentine. There are quite a lot of shades of glyptal enamel GF-230, ranging from light cream to dark colors. It can be applied with a brush, roller or sprayer. It dries for about a day and has a pronounced smell of varnish.

Alkyd enamel PF-133

It is used for painting metal surfaces or surfaces subjected to a preliminary primer. It is usually applied in two layers, since its covering power is not too high (ranging from 20 to 120 g/m2). Dries within 2 hours and has 15 not too bright shades. In a temperate climate, PF-133 enamel retains its protective properties for 5-6 years, while it does not crack or deform.

Alkyd enamel PF-115

Designed for outdoor painting of metal, wood and other surfaces. It is necessary to apply such enamel in two layers, since its covering ability is not too high (30-120 g / sq.m.). Available in 24 shades, applied by spray or brush, dries from 8 to 24 hours. Alkyd glossy enamel PF-115 has a pleasant sheen, giving the surface a bright, saturated color.

Alkyd enamel PF-223

Its scope is interior decoration wood and metal surfaces. Such alkyd enamel for radiators fits perfectly - it has 17 shades for every taste, hides old paint well and withstands high temperatures. It is diluted to the desired consistency with solvent, gasoline or xylene. Drying time 30-36 hours. The smell is specific, pungent.

Alkyd enamel PF-253

Scope of application - plank floors, previously primed. Apply in two coats with a wide or medium brush. Diluted with turpentine or gasoline. Dries quickly (drying time depends on the thickness of the layer and temperature regime indoors). After drying, the surface acquires a smooth, flawless gloss.

Alkyd enamel PF-126

This type of enamel is sold complete with NF-1 filler, which accelerates hardening. The paint is applied with a brush or roller in two thick layers with an intermediate drying time of 30-40 minutes. Before application, the surface is primed with enamel diluted with white spirit.

Matte enamels

Sometimes alkyd matt enamel may be required for painting surfaces. As a rule, such paint is intended for both exterior and interior work. It is durable, resistant to water, detergents, oils. It is able to withstand temperature fluctuations from -50 to +60 ° C. It is economically consumed, as it has a high covering ability (90-180 g / sq.m.). Diluted with solvent or white spirit.

Aerosol enamels

Aerosol alkyd enamel is easy to use, since there is no need for brushes and rollers, it fits well on any surface and dries very quickly (3-5 hours). She is able to penetrate into any cracks, so she is recommended to paint hard-to-reach places, and the scope of such paint is very extensive: from garden furniture to stucco on the ceiling.

In addition to the above, there are other types of alkyd enamels, the purpose of which also applies to painting walls, ceilings, floors and other surfaces both outside the house and inside it.

Manufacturers of alkyd enamels

On the shelves of stores you can find a huge range of alkyd enamels, both Russian and foreign. How do the first differ from the second?

Firstly, Russian manufacturers for the most part do not rely on packaging: paints are “dressed” either in metal or plastic cans. Imported enamels, as a rule, have bright attractive packaging that distinguishes "overseas" products from Russian neighbors.

Secondly, the price of 200-300 rubles per liter jar will obviously not suit high-quality alkyd enamel, and it is precisely such price tags that are sometimes found on the shelves with Russian products. Import analogues many times more expensive.

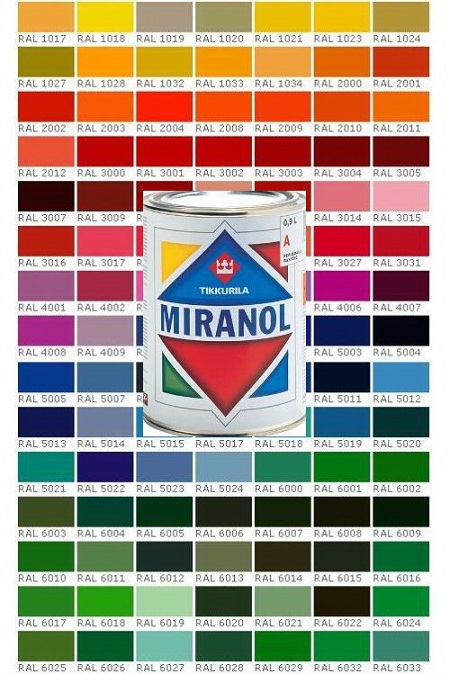

Thirdly, the composition of expensive imported enamels includes only the highest quality components that have passed all kinds of tests. It is due to such “ingredients” that enamels produced abroad practically do not smell, dry quickly, have a huge number of shades and are well distributed over the surface, leaving no streaks or smudges. For example, Miranol Tikkurila alkyd enamel is ideal for painting furniture, window frames, doors and even children's toys - its security level is so high. It is not yet possible to say something similar about Russian enamels, although our manufacturers have recently been trying to pay as much attention as possible to the environmental friendliness of their products.

When buying alkyd enamel, you should pay attention to its expiration date - the fresher the paint, the better and smoother the coating will be. Well, and most importantly - you don’t need to chase cheapness or high cost - choose the “golden mean” - you definitely won’t lose!