During the construction of the house, it is planned to lay water supply and sewer outlets. If there is no centralized sewage system in your area (dachas, country and private houses), the installation of a special device for the removal, filtration and purification of domestic wastewater is considered - a septic tank. This is a treatment plant that will make life easier for the owners and save the environment from pollution. Before designing, you should study the soil at the installation site, calculate the estimated amount of drains and choose the septic tank that suits you from the many varieties, as well as draw a diagram of the septic tank from concrete rings with your own hands.

Types of septic tanks

Traditionally, wastewater treatment plants are classified according to the following criteria:

- the type of work;

- material of manufacture;

- location of containers.

Let's consider them in more detail.

Features of septic tanks by type of work.

Septic tanks by type of work are selected depending on the daily amount Wastewater. They are:

- Cumulative. This is a cesspool type cesspool. All waste is collected in the well until filling. Cleaning is carried out with the help of sewage equipment 1 time in 2 - 3 months. Such designs are best used in places not a large number drains, for example, in the country.

- With soil treatment. This septic tank is used in places of permanent residence and a large number of drains. It works on the principle of division into fractions and consists of two chambers. In the first, large wastes are retained, and in the second, the incoming water is purified with the help of special bacteria and discharged through the filtration fields into the soil. Such a septic tank requires cleaning 1 time in 2 - 3 years.

- With deep biological treatment. Such a structure produces almost complete cleaning water. The principle of operation of such a septic tank is to separate wastewater into light and heavy fractions, and then the water is purified using bacteria and aerators. At the last stage, the water is disinfected with chemical substances, so it can be used for irrigation or dumped into a pond. Its feature is the connection to the mains. In such a septic tank there is very little unprocessed waste, so sewage equipment can be used once every 5 to 8 years.

The choice of a septic tank according to the material of manufacture

Septic tanks may differ in the material of manufacture. For example:

- Plastic and fiberglass. Good tightness, low weight and resistance to corrosion make it possible to install without special equipment and guarantee long operation. Not suitable for soils with a close location of wastewater.

- Brick. This is the availability of materials, easy installation, but requires additional tightness.

- Reinforced concrete. Reliable and durable construction. Suitable for mobile soils.

- Metal. Not the best choice because it is prone to corrosion.

Characteristics of septic tanks by location of tanks

Depending on the location of the tanks, there are vertical and horizontal septic tanks. Horizontal requires a large installation area, but it can be installed in case of close proximity ground water. And the vertical one is installed in standard conditions.

Features and benefits of a concrete septic tank

![]()

A concrete septic tank is one of the easiest and most economical ways to drain sewage. This design is very reliable and durable, does not require an electrical connection and will not rise under the influence of sewage. A concrete septic tank can be either a monolithic structure or assembled from concrete rings.

Benefits of a concrete septic tank:

- Environmental friendliness. Better wastewater treatment is carried out, and good sealing will protect against soil contamination with household waste.

- Durability. Unlike metal and plastic containers, reinforced concrete structure more hardy to environmental conditions (suitable for any soil).

- economy. The design of such a well is simple, available for installation by a non-professional. Low material and installation costs. There is no need to frequently call the cesspools.

- Size selection. It is possible to install a sump of any height and diameter, depending on the need.

- Reliability. The concrete structure is reinforced with metal rods and will withstand any load. It is not prone to destruction and, due to its large weight, withstands the movement of soil and sewage.

- autonomy. Does not require connection to electricity and installation of pumps.

Scheme of a concrete septic tank

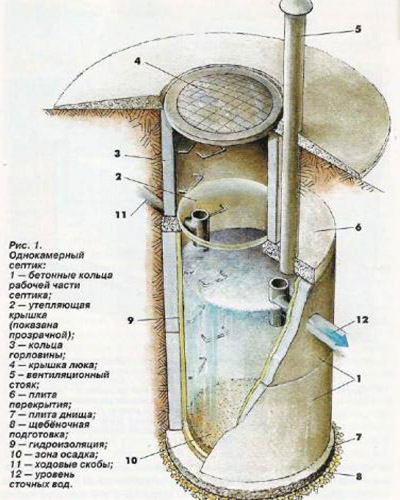

A concrete septic tank consists of several sections. Typically, a septic tank scheme made of concrete rings is 2 or 3 interconnected wells, each of which performs a specific function. Consider the most common design of 3 wells.

The first well (storage) is intended for the accumulation of solids and must be with a concrete bottom to prevent sewage from entering the ground. It separates waste into solid and liquid particles. The solid part precipitates and remains in the first section, while the liquid part enters the second well (filter) through a connecting pipe.

The second and third sections may be slightly smaller or the same size as the first. In the second well, secondary wastewater treatment takes place, after which they enter the third tank ( drainage well). From here, the liquid through the drainage pad at the bottom is removed into the soil, or pumped out using a pump. In the design of 2 sections, the second well is excluded, and the function of cleaning and drainage is performed in the third.

Installation of a concrete septic tank

![]()

Correctly making a septic tank from concrete rings is not so difficult. To install a cleaning system of this type, you need to choose a suitable place, taking into account the location of groundwater (no closer than 1 m) and provide free access to sewage equipment. For installation, a pit is dug a little larger than the size of the rings. The first well is placed on a concrete slab or the bottom is poured with concrete in place. A pipe is brought to it from the house along a slight slope. The rings are fastened together with cement or special metal plates to prevent shifting during operation. The seams between the rings and the pipe supply are carefully sealed. For this, silicone grease, liquid glass or special mastic is used. The second and third wells are mounted according to the same principle, only the second one also has a concrete bottom, and in the third a pillow of sand and gravel is poured onto the bottom. The tanks are interconnected by pipes with a diameter of 50 mm or more, each of which is placed 200 mm lower than the previous one.

Tip: To ensure the normal functioning of the septic tank in the winter, protect the well from frost and create a suitable environment for bacteria to work, the sections should be thermally insulated with polystyrene foam, polystyrene or any biofuel.

On the final stage hatches are installed and wells are covered with earth.

The price of a septic tank made of concrete rings

The cost of installing a concrete septic tank includes the price of concrete rings, materials for hydro and thermal insulation, sand, gravel, cement and other materials. Due to the heavy weight of the structural elements, special equipment will be required to lift the rings and an excavator to dig the pit. You will also need to pay for the work of the construction team if you do not plan to do the installation yourself. But even taking into account all these costs, such a septic tank will come out cheaper than a finished factory plastic construction. Therefore, calculate the budget for the installation of a septic tank and make a choice. More accurate prices for materials can be found on the Internet on sites selling building materials.

Concrete rings serve good material for the manufacture of sewerage in a private household. A septic tank made of concrete rings allows you to organize wastewater treatment up to 70%, but the percentage of treatment in it is lower than in high-tech biological stations (98%). If the territory does not belong to nature protection zones, then you can save on sewage, since the cost of such a septic tank is half the price of buying a treatment station.

Before starting work, it is necessary to determine the type of soil on the site. The choice of a filtration system depends on its characteristics, since the design of a septic tank made of concrete rings involves several containers. According to sanitary standards, water must be subjected to three or more days of settling before it is discharged into the ground.

The type of soil can be determined by digging a hole, by interviewing neighbors who own a well or a well, by requesting information from an organization conducting construction or drilling near the site.

If the site is located in a hilly area, with a high degree of probability it has a rock type soil. In this case, you need to make a choice in favor of ground purification stations or storage tanks.

The throughput of clay is practically zero. Soil of this type belongs to the category of impervious rocks - water-repellent rocks that do not absorb and do not pass water through their thickness.

The filtration coefficient is slightly higher for loams, slightly higher for sandy loams. However, their filtration properties are still not enough for the installation of systems for ground wastewater treatment on the listed clay soils.

In addition, almost all clay soils are characterized by heaving - the ability to increase in size during freezing and decrease during thawing. These ground movements can easily push concrete containers outward, completely destroy them, or simply squeeze them until cracks appear.

Sandy, gravel, pebble and rubble sedimentary rocks have good absorbing properties. They freely pass water into their thickness, do not prevent its movement to the underlying layers. True, large-clastic deposits, such as gravel and pebbles, occur mainly in floodplains, and crushed stone at the foot of mountain formations.

On river and mountain slopes, filtering facilities are not suitable, because. part of the draining liquid will not be able to pass a post-treatment cycle sufficient for disposal into the soil. Therefore, sandy soils of all degrees of fineness and density of addition, except dusty, are considered normal conditions for the construction of filtration fields, absorption wells and the installation of infiltrators.

In addition to geological conditions, it is necessary to observe the norms of its location from residential buildings and water sources.

This information is written in sanitary standards and must be observed. It is worth avoiding the location of the septic tank close to the place where trees grow, as they root system may damage the structure.

If hygiene standards are neglected, biological contamination of water may occur. Dangerous pathogens of infectious diseases develop in sewage. These include E. coli, which causes severe poisoning. She easily gets to the source drinking water through groundwater.

How to calculate the required volume

To organize a septic tank from concrete rings, it is necessary to calculate the volume based on daily water consumption. According to the norms, there are 200 cubic liters of water per day for one permanently residing person.

The first container for settling wastewater should not have a volume of three times the amount of consumption (200 liters) per person. The second container with a bottom for settling should have a volume equal to 1/3 of the size of the first. The number of rings can be determined by dividing the volume of the container by the volume of the ring. Their sizes are small, medium and large.

For the calculation, the parameters of the medium-sized ring will be used. KS-10-9 whose inner diameter is 1 m and height - 90. One ring has a volume of 700 cubic liters

For a family of two:

The volume of the first container = (200 * 2) * 3 = 1,200 cubic liters.

The volume of the second and third containers = 1 200/3 = 400 cubic liters.

Number of rings for two containers = (1200+400)/700= 4

Number of rings for three containers = (1200+400+400)/700= 5

2 rings for the sump, 2 for the settling tank and one for the drain well

For a family of three:

The volume of the first container = (200 * 3) * 3 = 1,800 cubic liters.

The volume of the second and third containers = 1 800/3 = 600 cubic liters.

Number of rings for two containers =(1 800+600)/700=4

The number of rings for three containers \u003d (1 800 + 1200) / 700 \u003d 6.

2 rings for the sump, 2 for the settling tank and two for the drainage well.

Types of septic systems

Schemes of septic tanks made of concrete rings suggest the presence of one, two or three chambers, where wastewater is settled and biologically processed.

A single-chamber septic tank provides three-day settling of wastewater. It requires pumping out excess sludge every 3-6 months. Cleaning quality does not exceed 50% (+)

In fact, a single-chamber septic tank is a conventional storage tank, the drains from which are pumped out by sewers.

A two-chamber septic tank provides 5-6 daily settling of wastewater. The cleaning level is 70%. It is necessary to pump out excess sludge every 12 months

The first and second containers must have a bottom. This is followed by the third compartment, where soil cleaning is also carried out. The next stage of purification is the withdrawal of excess runoff into the ground through the bottom of the filter well.

A three-chamber septic tank provides 7-9 daily settling of wastewater. The cleaning level is 80%. It is necessary to pump out excess sludge every 2 years (+)

All chambers are arranged with a monolithic bottom, cleaning is carried out by settling. The settled liquid is discharged into the infiltrator or filtration field for subsequent disposal into the ground.

Depending on the absorption capacity of the soil, you can choose several filtration options for installing a septic tank from concrete rings:

- Septic system with filter field.

- Septic system with drainage well.

- Septic system with a filter cassette (infiltrator).

The most common filtration option is a drainage well. It is used when the soil has good absorption properties.

To increase performance, its bottom ring is perforated. This increases the filtration area. If the groundwater level is less than three meters, this option should be abandoned (+)

Between the level of the conditional bottom of the absorption well and the highest level of groundwater in the autumn / spring rainy period, there is no meter required by the standards, a filtration field is established. For its construction on the site must be enough space.

When installing it, perforated pipes or tunnels are used. To evenly distribute wastewater between the septic tank and the filtration field, a distribution well is installed.

This is the best solution for areas where the groundwater level does not exceed 2.5 meters. It should be remembered that between the lower edge of the drainage pipes of the filtration field and the roof of the water-saturated formation there must also be a soil thickness of at least a meter.

The filter cassette is similar to the filtration field, but it is more expensive. This is an average between a filter well and an aeration pipe system. It consists of a rectangular concrete tank, with several baffles inside. From above, the structure is closed with concrete slabs (+)

This design is not widely used in the CIS countries.

You need to decide on the filtration system before installing a septic tank from concrete rings, as this will allow you to prepare a pit of the required size and depth in advance. If filtration systems are installed after installation, pipes and tanks can be damaged. Therefore, the space that borders the wall of the second settling tank will have to be dug manually, without the use of special equipment.

Installation of a septic tank with two settling tanks

Before starting work, it is necessary to check the level of groundwater. This can be done if the house has a cellar or basement, without a concrete bottom. It is necessary to measure the height from the ceiling to the surface layer of the soil. This is the depth to which you can dig.

To find out how deep the groundwater lies, you can dig a small but deep hole. Groundwater begins when clearly damp earth appears. This is a sure sign, no need to dig further.

The depth of groundwater occurrence can be determined by appearance extracted from the pit of soil. If it is saturated with water, then the depth of its extraction can be taken as an independently determined groundwater level

After the approximate GWL has become known, earthworks can begin. It is necessary to outline the place where the septic tank will be located. To do this, you need to outline the pits. To do this, you need to take a construction or any strong thread, measure 80 cm. Tie two pegs to both ends.

Insert one end into the middle of the place where it is planned to place the first settling tank. Draw a circle. This is the approximate diameter of the desired hole. Next, you need to retreat the meter, and draw the boundaries for the second container. Next, you need to outline the boundaries of the filtration structure.

The boundaries of the pit must be surrounded by pegs around the perimeter, between which a thread is pulled. This makes it easier to navigate when excavating

Consumables and tools

Before you start, you need to collect everything necessary materials and tools. For work you will need:

- perforator and large drill for concrete;

- nozzle mixer to the perforator;

- shovel and bayonet shovels;

- stairs;

- level:

- buckets;

- container for mixing the solution;

- strong nylon rope;

- hose;

Materials for mounting a septic tank from concrete rings:

- cement;

- sand;

- gravel;

- bitumen or liquid glass;

- metal staples;

- Mineral wool or polystyrene foam;

After the equipment for all stages of work has been selected and prepared, you can start digging a hole.

How to dig pits for a septic tank

If you think that it is difficult to excavate the soil in such volumes manually, then you can use the services of organizations with special equipment.

Together with digging the pit, it is necessary to order the removal of excess soil, since the deep layers are usually loam and are not suitable for use in garden plots.

At the bottom of the pit it is necessary to pour sand, where the lower rings of the tanks will be installed. The thickness of the sand cushion is 20-25 cm. The base must be leveled. Next, the sand must be shed with water so that shrinkage occurs. After compressing the sandy base, you can proceed to the installation of the rings.

Installation of sedimentation tanks

To install pre-delivered concrete rings for a septic tank, you need to build a base. To do this, a wooden formwork is arranged along the perimeter of the bottom of the pit. The height of the formwork walls should be at the level of 30-40 cm. After the construction of the formwork, it is necessary to lay the reinforcing mesh and dilute the cement mortar. To do this, you need to take 1 part of cement for three parts of ASG (a mixture of sand and gravel).

You can mix the solution with a construction mixer. As a plasticizer, two tablespoons of liquid soap can be added to the solution. This will make the concrete more resistant to pressure and moisture. After pouring the base, you need to wait 10 - 14 days until the solution hardens and acquires the necessary strength. Formwork may not be removed. If rented equipment is used, it is more advisable to purchase ready-made concrete slabs as a base.

After the base is ready, you can mount the rings. The weight concrete structures imposing, so it is necessary to use a crane. Installation of containers takes place in stages.

On the concrete base immerse the first ring. Following it, the second one is lowered and installed. The ring must be moved smoothly, avoiding its impact or slipping. After installation, bracing is done.

Holes are made in both rings along the edges, iron brackets are inserted into them, which are bent from the outer sides of the containers

At the next stage, until the lid is lowered, it is necessary to cover the seams between the rings. After installing the overlap in the tank, it will become dark and there is a risk of leaving raw joints. For this, cement mortar is used. For ease of movement, running brackets are mounted inside the tank. They are necessary for the maintenance of the septic tank, in case of blockages or depressurization.

The adjacent settling tank is installed in the same order. In both containers, you need to make holes for sewer pipes and mount them. The sewer inlet must be higher than the overflow pipe between the tanks.

On top of the floors, you need to install one concrete ring of small diameter. Thus, a small chamber is obtained that will isolate the container from cold air.

This completes the installation of a septic tank from concrete rings, and the installation of a ventilation system follows.

Ventilation system installation

Ventilation is necessary to allow air to enter the system, which ensures the normal functioning of microorganisms. They process domestic wastewater and free it from the organic component. To ensure constant circulation of air flows, two ventilation pipes are required.

The first pipe is mounted in the section of the sewer pipe, which is as close as possible to the walls of the residential building. The best solution would be to install inside walls, but can also be mounted outside (+)

In this case, it will be necessary to lay an electrical cable to warm the pipe, since when warm and cold air collide, condensation forms in it, which blocks the access of oxygen. It must be fixed with fasteners or clamps. The vertical length of the background riser must be at least the height of the wall of the house.

Ventilation also eliminates unpleasant odors that periodically emerge from containers and can spread throughout the home. Often this happens with a long absence of residents and the drying of the liquid in the siphon.

The second pipe is mounted in the ceiling of the sedimentation tank. To do this, using a perforator, a hole is punched in the ceiling, matching the diameter of the ventilation pipe. The air duct should rise above the earth's surface by 70-100 cm. The position of this pipe will be fixed by the weight of the soil and does not need additional fastening.

Installation of aeration field

A pipe exits the second concrete tank into a distribution well. For a well, you can use a plastic barrel in which to cut holes suitable for aeration pipes.

You can purchase a ready-made distribution well.

It is produced by many companies that manufacture cleaning systems. You can buy a ready-made aeration field for the distribution well or make it yourself from sewer pipes

To do this, you need to purchase pipes based on the size of the field. For a family of four, an area of 20 is enough square meters(10×2). To do this, you will need three pipes 10 m long. In addition, you will need three corner pipes where the ventilation pipes will be mounted.

The field is pre-filled with sand and gravel to improve the absorption capacity of the soil.

Perforated pipes connected to a distribution well are laid on the prepared drainage. Corner pipes are mounted at the ends of the aeration pipes, into which a background riser is installed, one for each pipe. After that, the pipes are covered with geotextile and covered with a mixture of gravel and sand, then leveled. As silting occurs, the aeration field must be moved or cleaned, changing the drainage.

Installation of a filter well

The filter well has a number of advantages over the aeration field. It occupies less usable area on the site. But the quality of treated water will be higher near the aeration field, since before entering the groundwater, the effluents will be filtered by soil, and its layer under the aeration field is much larger than that of a well with drainage. The well area cannot cope with the amount of effluent that the aeration site accepts.

It is necessary to locate the filtration well at a distance of at least 2 meters from the settling tank. This is necessary in order to exclude the movement of the soil and the deformation of the foundation in case of emergency leaks and flooding.

Installing the well is based on the same principles as the sedimentation tanks, excluding concreting the bottom of the tank. At the bottom of the well, in addition to the sand cushion, crushed stone, gravel, or other filter composition should be placed. The standard capacity of a soil filter in an absorption well is calculated from 1 m or more.

To increase its throughput, you can supplement the filtration well with lateral drainage. For its device, the lower concrete ring of the septic tank must be perforated.

You can find models of rings that already contain holes, but it is difficult to find them. Therefore, it is more expedient to make holes yourself with a puncher.

This process is best done on the surface, before the ring is lowered into the pit. You also need to make a hole for overflowing water from the sedimentation tank, it should be slightly lower than the previous overflow.

The walls and joints of the filter well must be stapled, but there is no need to seal them. By connecting the overflows, you can bury the structure. The first ring must be sprinkled on the outside with crushed stone, to the junction with the second segment. The rest of the volume can be covered with soil from the plot.

Pre-launch process

If the temperature in winter drops below 30 degrees, it is necessary to prepare insulation for the inner hatch cover. Since the container itself is located below the freezing level, it does not need additional insulation.

To insulate the cover, you need to take the foam and cut out a circle that fits the diameter of the inner small concrete ring.

Styrofoam is practically not subject to decomposition and will last for many years. To make it convenient to remove it to check the septic tank, you can make a hole in the middle where you can insert a nylon rope. On the back of the foam, the rope must be tied to a short and narrow board, and the other end left

Next, you need to cut out the cover itself. For this, ordinary plywood of sufficient strength is suitable. You can screw the door handle to it in order to conveniently open it. Similarly, it is worth insulating the inner covers of the second sedimentation tank and the drainage well.

Before using the septic tank, the first settling tank must be filled with water to 1⁄4 of its volume. Pour a biological product into the filled container, which will help the septic tank reach full capacity faster. After these steps, it is necessary to close the hatches.

Video how to install a septic tank

The video shows the process of installing a two-chamber septic tank in stages:

How does a septic system work:

If the construction of a septic system of concrete rings is done in compliance with the rules, it will last for 20 years. We must not forget about the rules of operation and timely maintenance. The pipes are made of plastic, so they are easily damaged. It is strictly forbidden to put equipment or a car in the place where the tanks are located.

If plastic septic tanks do not inspire confidence in you, make your own, with aeration and separate chambers. For these purposes, the most profitable option is concrete rings, and today we will tell you how to properly install them, waterproof them and run a communications network inside.

Scheme and principle of operation of a septic tank with separate chambers

Septic tank - a general definition of systems for multi-level wastewater treatment, which are based on the use of natural biological processes. Unfortunately, most of the “branded” products are just an attempt to standardize the work of the WTP, although such structures have always been built only according to individual project, which takes into account:

- soil and relief features;

- ground water level;

- temperature regime;

- chemical composition drains.

A number of more specific indicators are often added to this list.

In home construction, a septic tank requires a sensitive approach, organization and planning of the operation of the structure in all possible modes, including emergency ones. All processes related to both clarification of water and protection of chambers from negative external influences must be worked out to the smallest detail.

The first chamber is a sealed column of the primary clarifier (PS). Its volume is determined at the rate of 200 liters per person per day for at least three days in case of emergency work. The capacity of the software is equivalent to the capacity of the second chamber (reactor or aerotank), respectively, it is necessary to take into account the possibility of a triple salvo discharge, saving the septic tank from self-flooding.

An ordinary septic tank uses the gravitational principle of moving water between chambers and in no way contributes to the rapid development of bacterial colonies. Septic tanks equipped with an aeration system and wastewater movement have an accelerated cleaning regime due to the involvement of aerobic microorganisms in the process, but require expensive technical equipment and are energy-dependent: up to 1.4 kWh / day and about 3-5 kWh / day at running heating.

As a warning, we will make a short digression regarding the preparation for the arrangement of a septic tank. Lay the underground part of the inlet line of the septic tank with a HDPE pipe 125 mm SDR 17. Its inner diameter allows you to stretch about 50 cm at the end of the 100 mm sewer pipe, free from the socket. It is better to drain clarified water with the same pipe, but with a diameter corresponding to the drain pump fitting.

What rings and how to dig them in

One of the key properties of a septic tank is the tightness of the chambers of the software and the aeration tank. Without this, runoff will seep into the perch, polluting drinking water sources, worsening soil characteristics, which will attract the attention of sanitary and epidemiological control services.

When dealing with rings, it is difficult to achieve a deaf waterproofing: winter heaving breaks the joints, the rings are displaced by soil movements. High-quality insulating materials alone are not enough, a system for fastening rings is needed.

Another problem with any sealed chamber is that its equivalent density may be lower than the density of the soil, so over time the septic tank will begin to squeeze out. All this leads to the conclusion that the standard well shaft from the rings according to the method of sequential digging in is clearly not enough.

Rings must be used with a quarter (lock) for reliable docking. First, a pit is dug to the desired depth, with a diameter of a meter more than the rings. The bottom is filled in two stages. The first bottom layer is 80 mm, reinforced with mesh, with four anchors diametrically removed from the center to the outer radius of the ring. The second layer is poured the next day with 30 mm sand concrete, then, even before setting, the lower ring is lowered into the pit and installed between the mortgages.

Previously, the rings of the first two chambers must be treated with one or two layers of coating waterproofing. The locks at the ends are especially carefully opened, and a fresh layer of mastic is applied when installing each new ring. It is recommended to fasten through the walls of U-shaped brackets with threaded ends from the final calculation every 40 cm.

After installing the shaft, it is covered with a cap with a release on the sides of at least 150 mm at a level of 100-120 cm below the ground. According to the location of the mortgages, 16 mm holes are drilled in the cap, then the container is pulled together with heat-strengthened fittings with a diameter of 14 mm on threaded rods. The throat of each chamber can be assembled from rings, but with a high level of groundwater, it is better to cast it in one piece with a cap or arrange an earthen castle at the level of the top water.

From the outside, the columns are covered with a layer of foamed polyurethane foam, possibly with a foil backing. Not for the purpose of insulation, but as a means to compensate for the heaving of the soil, and prevent it from freezing to the rings. The remaining space can be covered with road gravel, but often it is filled with excavated clay - this depends on the type and composition of the local soil.

Not all containers are the same

The water leaving the second chamber is 99% free of solid particles and fat, but is biologically contaminated and requires additional treatment in the soil layer. So, contrary to the "heralds" from marketing, it is categorically not allowed to dump water from a septic tank onto a relief.

The well of perforated rings will perfectly cope with the function of the filtration field. You can dig in the rings sequentially, but it’s better to start with a foundation pit and arrange 20-cm gravel filling on the sides, preventing the holes from silting up. To simplify earthworks, you can replace one deep tank with a smaller pair. It is also preferable to remove the filter well from the septic tank chambers by 5-7 meters so that the soil around the chambers is less saturated with moisture.

When laying the upper rings, do not forget to leave the mortgages connecting the first chamber with the second and the second with the third by means of 110 mm meter lengths PVC pipes located with a level difference of 50 cm. Lay a HDPE pipe with a diameter of 70 mm from the bottom of the second chamber to the middle of the first. Also, do not forget to connect the aeration tank with a HDPE pipe to a filter well. The pipe outlets in the first chambers are sealed and sealed, then they are completed with vertically oriented tees so that the overflowing liquid is taken from a layer 2-3 meters below the surface, where there is no solid silt and light fragments.

1 - inlet wastewater pipe; 2 - tee; 3 - primary sump; 4 - aeration tank; 5 - drainage well; 6 - HDPE pipe Ø110; 7 - HDPE pipe Ø70; 8 - crushed stone (gravel)

1 - inlet wastewater pipe; 2 - tee; 3 - primary sump; 4 - aeration tank; 5 - drainage well; 6 - HDPE pipe Ø110; 7 - HDPE pipe Ø70; 8 - crushed stone (gravel)

Septic tank aeration system

To maintain the vital activity of aerobic bacteria, it is necessary to periodically pass air through the treated wastewater - about 1300 l m 3 / h. The more air bubbles are sprayed, the more efficient and faster aeration takes place. Membrane diffusers used in fish farms to supply oxygen to pools do a good job of this. They need to be located a meter from the bottom of the aerotank in an amount of from one to three pieces, depending on the size and performance of the entire system.

1 - compressor; 2 - silicone tubes; 3 - membrane diffuser

1 - compressor; 2 - silicone tubes; 3 - membrane diffuser

Diffusers are connected by means of silicone tubes led through overflow pipes to the neck of the tank. The compressor can be located either on an equipped site inside the aerotank, or in a caisson equipped next to the tanks.

Moving masses between chambers

The septic tank must be equipped with a submersible slurry pump, which will not only prevent flooding, but also help with periodic cleaning of accumulated waste sludge. By default, it is suspended in the middle of the second tank, but the float is placed half a meter above the outlet. So the pump will urgently get rid of excess clarified water by dumping it into the filter well, and will not allow the septic tank to flood itself.

1 - cable; 2 - float; 3 - drainage pump; 4 - tubular diffuser

1 - cable; 2 - float; 3 - drainage pump; 4 - tubular diffuser

Through the second embedded pipe between the chambers, activated sludge is pumped into the primary sedimentation tank, which accelerates the growth of bacteria and the operation of the entire septic tank. In order not to use another pump, the end of the pipe smoothly lowers 30 cm from the bottom, and a productive tubular diffuser is installed inside, which works like an airlift with a lift height of up to two meters.

The septic tank belongs to the local treatment facilities. It is resorted to construction in the absence of a centralized sewerage system.

The conversation in the article is exclusively about one type, namely, a septic tank, for the construction of which ready-made reinforced concrete rings are used.

Like any other, this type has its strengths and weaknesses.

By design, a septic tank can contain from 1 to 3 wells made of concrete rings interconnected into a common system.

Photo: types of septic tanks - single-chamber two-chamber three-chamber

When choosing a septic tank scheme, it is necessary to focus on the following factors:

- daily water consumption at the facility;

- terrain;

- groundwater level on the site and its seasonal fluctuations;

- depth of soil freezing for a given area;

- accessibility for trucks.

The calculation of a septic tank is to determine its volume. It depends on the daily water consumption.

The working or effective volume of the septic tank is taken equal to three times the discharge of water per day. 1 person spends about 200 liters during this time. This figure, multiplied by 3 and the number of residents, is the capacity of the septic tank.

This refers to a septic tank with more than one chamber. The volume from the bottom to the level of the overflow pipe into the secondary chamber is considered effective for it.

The actual volume of the septic tank may be greater than the calculated one, but not vice versa.

Photo: scheme of a septic tank made of concrete rings

Photo: scheme of a septic tank made of concrete rings Operating principle

A single-chamber septic tank works on a cumulative principle. The larger its volume, the less often it will have to be pumped out.

In multi-chamber septic tanks, wastewater is separated into fractions. The solid phase, being heavier, settles and accumulates at the bottom, lighter ones remain on top. As the level in the primary chamber rises, there comes a point when liquid begins to flow into the second chamber.

The clarified wastewater entering the second chamber is settled again. The liquid entering the third chamber (filter well) already contains practically no solid suspended particles. Through a layer of filter material at the bottom, it goes into the ground.

Photo: the principle of operation of a septic tank

Photo: the principle of operation of a septic tank Place for installation

The septic tank is located in such a way that a distance of at least 30 m is maintained to the source of water supply (well, well).

If the site has a slope, then the septic tank should be located lower on the slope than other structures.

The head of the septic tank with a lid must have an elevation sufficient to avoid melt and rain water from entering the well.

Photo: installation site

Photo: installation site High groundwater design

The groundwater level is considered high if water appears at a depth of 0.5 to 1.0 m. This creates significant difficulties in the construction of a septic tank.

The difficulty lies not so much in earthworks, but in the problem of tightness of septic tanks. This is especially true for a septic tank made of concrete rings.

Important! It is very difficult to ensure 100% quality of the waterproofing of the joints of the rings. Usage modern materials allows you to achieve this, but the slightest leak will lead to the rapid filling of the septic tank.

Not only the effective sedimentation of wastewater is in question, but the operation of the septic tank itself. Even if the waterproofing is perfect, there is no reason to rely on soil filtration.

The way out in this case can be an additional elevated filtration area - a layer of soil in the form of a hill.

In this case, it will be necessary to use drainage pumps, which will lead to an increase in the cost and complexity of the overall design.

It is possible that in this case it would be expedient to abandon the use of concrete rings in favor of hermetic containers such as barrels, cisterns and eurocubes.

Distance from home to septic tank

The distance from the foundation of the house to the septic tank should not be less than 5 m. But it cannot be made excessively large either.

Important! Sewage pipe should be laid with a slope of at least 2.5 cm per meter of length at a depth of 0.8-1.0 m from the surface. With a large distance, the pipe will enter the septic tank too deeply.

In this case, two options are possible - to accept the loss of usable volume or to increase the depth of the well.

The liquid level in the septic tank should not rise above the sewer pipe, otherwise there will be a backwater that prevents the normal operation of the sewer.

Construction

Work on the construction of a septic tank includes several main stages:

- the first of them is earthworks - digging a pit and a trench for a sewer;

- after that, you need to mount the structure - install concrete elements. pipes, etc.;

- after waterproofing, soil is backfilled around the rings;

- covers are mounted.

The septic tank is ready for connection to the engineering systems of the house.

Digging a pit

Excavation work can be done manually or with the help of mechanization.

The choice of method depends not so much on the cost of special equipment services, but on the availability of access roads and the availability of free space for excavated land.

When building a new house, it is still better to dig a foundation pit with an excavator. This will greatly facilitate and speed up the work, because the bill goes to more than a dozen cubic meters.

One nuance. When digging with a bucket, a hole is obtained, the shape and size is much larger than that needed for a septic tank. It will not be easy to lower concrete rings weighing from 400 kg into such a pit on your own. Most likely, you will have to resort to the services of a crane with a long reach.

Digging by hand will take much longer, but will allow you to dig a pit exactly to size. The diameter of the well under the ring is taken with a margin of 20 cm per side.

To extract the soil, a manual or mechanical winch is used. At least two people are required for operation - one at the bottom and one at the top.

We must not forget about safety. There is always a danger of soil shedding, the walls should have a slight slope or be strictly vertical.

Photo: digging a pit by hand digging a pit using special equipment

Photo: digging a pit by hand digging a pit using special equipment Mounting

Concrete rings for a septic tank cannot be rolled to avoid cracking.

Loading and unloading is carried out only in a vertical position. Installation of a septic tank begins with the preparation of the base for the rings. Its purpose is to reduce the effect of seasonal soil movements on the rings.

Photo: installing rings

Photo: installing rings As a basis, you can use finished products or make them on your own.

The bottom of the pit is leveled, a mesh of 20 * 20 cm is knitted from the reinforcement and poured with concrete to a thickness of at least 20 cm. The base can be separate for each well or common.

Photo: pouring the base with concrete

Photo: pouring the base with concrete Rings are placed on the prepared base. In the mounted rings, holes for pipes and tees are marked and punched in place. A powerful puncher and a grinder will handle this.

After all the connectors are in place and the drain pipe is inserted into the septic tank, proceed to waterproofing.

Having completed the waterproofing, you can start backfilling the rings. The space between the walls of the pit and concrete rings is filled with soil with compaction every 20-30 cm.

Waterproofing

The stage of waterproofing is one of the most serious, and you need to take it with all responsibility.

Contrary to popular belief, ordinary concrete does not hold water. Therefore, all internal and external surfaces of the rings are waterproofed.

Photo: septic tank waterproofing

Photo: septic tank waterproofing For this, bituminous mastic, a solution of liquid glass or well-proven polymer mastics, such as Hydrotex and Hydroizol, are used.

Particular attention should be paid to sealing the joints between the rings.

Photo: waterproofing the joints of the rings

Photo: waterproofing the joints of the rings Gives the best results concrete mix with special additives that make concrete waterproof.

Ventilation

The ventilation system of the septic tank must perform two tasks:

- eliminate unpleasant odors from wells and highways;

- exclude air rarefaction in sewer pipes.

Photo: ventilation

Photo: ventilation The sewer pipe of the septic tank is connected to the ventilation riser that goes to the roof of the building. The diameter of the riser pipe should not be less than the diameter of the pipe connecting the septic tank to the sewerage of the building. The optimal diameter of the waste pipe is 110 mm.

If the cross section is not large enough, the water flow covers the entire lumen of the pipe. As a result of the "piston" effect, water is sucked out of the siphons of plumbing fixtures, the water seal disappears. Sewer smells enter the room.

Types of septic tanks made of concrete rings and their features

Single chamber septic tank

Photo: single-chamber septic tank device

Photo: single-chamber septic tank device The septic tank, which has one chamber, serves as a reservoir for collecting sewage. Its volume should not be less than 16-20 times the daily discharge. Can be done without a bottom. Moreover, the device of any drainage with a single-chamber system is meaningless.

The process of soil filtration stops as siltation occurs as a result of the settling of heavy fractions.

Important! Waste water must not be allowed to seep through the joints of the rings.

Double chamber

Photo: two-chamber septic tank device

Photo: two-chamber septic tank device The septic tank, consisting of 2 chambers, is quite functional. Heavy waste accumulates in the first chamber. The settled water enters the secondary chamber. With proper arrangement of bottom drainage from gravel and sand, water completely or partially goes into the ground.

The working condition of a two-chamber septic tank is that the 1st chamber is constantly filled to the overflow level, the level in the 2nd depends on the discharge of waste and the filtration rate.

Three-chamber

Photo: three-chamber septic tank device

Photo: three-chamber septic tank device A septic tank with 3 chambers is the most advanced in terms of waste disposal. The first two wells act as settling tanks of varying degrees of purification; a third one is added to them, acting as a filter.

When digging a pit under the 3rd chamber of a septic tank in clay, it is very desirable to reach a sandy layer that passes water well. Water from such a well will be easily absorbed. On the contrary, a clay bottom will interfere with normal cleaning work.

The working position of a three-chamber septic tank is that two chambers are filled to overflow levels, the filter well has a certain liquid level.

without bottom

A septic tank well may not have a bottom in two cases - if the groundwater level is low enough and there is no danger of sewage entering the aquifers. And vice versa, when you want the water to go into the ground. To do this, several layers of sand and gravel are placed on the bottom.

With aeration

The process of decomposition of organic residues can be significantly accelerated if air is injected into the secondary chamber under pressure. Reaching the bottom, the air mixes the sediments with colonies of aerobic bacteria. Ammonia is decomposed into nitrites.

For forced aeration, a compressor with a timer is enough.

Without pumping

The title is rather arbitrary. A properly constructed three-chamber septic tank can be attributed to septic tanks without pumping out. Anaerobic processes take place in the first chamber.

Photo: septic tank without pumping

Photo: septic tank without pumping Solids that settle to the bottom are decomposed by bacteria into methane and hydrogen sulfide, the silt sediment is relatively small. Its quantity is the less, the deeper the process of decomposition.

If we add to this the aeration of the second chamber and good filtration of clarified waters from the third, then pumping out may be required very soon. This is not a myth at all, there are real examples of septic tanks that have been operating for 10-12 years without a single pumping.

Repair and service

Maintenance of a septic tank comes down to monitoring the level of wastewater in the chambers and, if necessary, pumping out.

After that, it is advisable to inspect the joints of concrete rings for leaks. Additional sealing of the septic tank may be required

The septic tank should function in the warm season or all year round, without interruptions. This is due to the nature of his work.

A positive temperature is maintained in the septic tank due to the heat released during the decomposition of organic matter.

The septic tank maintains itself in winter. Wastewater coming from outside also gives off its heat.

Important! If the sewage stops flowing, the decomposition process stops, the temperature drops. The system stops self-regulating. Instead of a living ecosystem, an ice pit is obtained.

Smells

If the ventilation system is correctly designed and correctly installed, then the septic tank does not give out any extraneous odors of its presence.

The necessary conditions for this are that the amount of sewage is within the normal range, the system is airtight, there are no leaks, the manhole covers are tightly closed, and the ventilation is working.

An unpleasant smell can appear when the organic matter does not have time to decompose, the bacteria do not cope with the "work". In this case, adding a bioactivator to the septic tank can help out.

This review does not exhaust the topics of concrete ring septic tanks. There is no doubt that this design enjoys well-deserved attention from developers. At right approach septic tank made of concrete rings for a summer residence, cottage or country house can work for a long time with high autonomy.

Among the new treatment systems that have replaced the stinking cesspools, septic tanks are especially popular. But since the cost of finished structures is not affordable for everyone, you have to make a septic tank from concrete rings with your own hands.

When sewerage in a country house or in a private house cannot be connected to central communications, the question of own treatment plant becomes relevant, and in this case a septic tank is the best option. Unlike conventional cesspools, it cleans household drains, making them safe for the environment, holds back unpleasant odors and, if properly managed, it may not take many years to pump it out. When deciding which septic tank to install, preference is often given to structures made of concrete rings.

Types and principle of operation of a septic tank made of concrete rings

The principle of operation of all septic tanks is the same, the difference lies only in the use of different materials for the construction of a septic tank in a private house and the number of chambers - tanks for collecting sewage.

- It is not advisable to install a single-chamber septic tank, since the filtration process

will stop as soon as siltation of the bottom occurs. To a large extent it depends

on the amount of wastewater and the volume of the septic tank, but long time such

the sewage treatment plant will not work. Frequent pumping out of settled fractions will entail additional costs for the services of a sewer and the launch of new bacteria. - A two-chamber septic tank is quite functional. In the first chamber, only fermentation and settling of effluents occurs when the bottom is closed, enough

treated wastewater that goes into the ground. The filtration rate depends on

the quality of the drainage system.

- A three-chamber septic tank is the most advanced option in terms of household waste disposal. In this case, the role of settling tanks is performed by the first two tanks, the water in them is of varying degrees of purification, and the third one acts as a filtration

fields. Therefore, when deciding which septic tank to make, it is better to dwell on this option.

Important! In working order, the septic tanks should be filled to the overflow level, and the filtration fields contain only a certain amount of purified water.

Calculation of the required volume of a septic tank

The volume of wastewater, and, accordingly, the volume of the container is calculated by the formula: the number of people living is multiplied by 200 liters, multiplied by 3 days and divided by 1000, the resulting number determines the required volume of the container in cubic meters.

200 liters is the consumption rate per person, of course, in fact it is much less. 3 days - the time during which the water in the septic tank is purified. If there are often guests in the house, a washing machine or dishwasher is used, it is recommended to add 200 liters to the volume. The volume of the second tank can be less than the first by 30%, and the third by 50%. Based on these calculations and knowing the volume of one concrete circle, it is easy to calculate how many of them will be needed.

tab. WELL RINGS REINFORCED CONCRETE

|

NAME |

OVERALL DIMENSIONS in mm. |

|||

|

wall thickness |

internal diameter |

the weight | ||

| KS -7-5 | 500 | 80 | 700 | 0,275 |

| KS -7-9 | 900 | 80 | 700 | 0,410 |

| KS -7-10 | 1000 | 80 | 700 | 0,457 |

| KS -10-2 | 300 | 80 | 1000 | 0,200 |

| KS -10-3 | 300 | 80 | 1000 | 0,200 |

| KS -10-5 | 500 | 80 | 1000 | 0,200 |

| KS -10-6 | 600 | 80 | 1000 | 0,400 |

| KS -10-9 | 900 | 80 | 1000 | 0,610 |

| KS -10-9 s / s | 900 | 80 | 1000 | 0,610 |

| COP -10-10 h | 1000 | 80 | 1000 | 0,660 |

| KS -12-10 | 1000 | 80 | 1200 | 1,050 |

| KS -15-3 | 300 | 80 | 1000 | 0,200 |

| KS -15-6 | 600 | 80 | 1500 | 0,670 |

| KS -15-9 | 900 | 90 | 1500 | 1,00 |

| COP -15-10 h | 1000 | 100 | 1500 | 1,240 |

| KS -20-6 | 600 | 100 | 2000 | 1,20 |

| KS -20-9 | 900 | 100 | 2000 | 1,50 |

Septic tank made of concrete rings: construction stages

Sewerage with a septic tank made of concrete rings is distinguished by reliability, durability and a high level of cleaning of household sewage. The price of such a structure will be relatively low, and with excellent waterproofing and the correct scheme, it will not be necessary to pump out the tanks often. The difficulties of construction include the need to attract heavy equipment and the peculiarities of installing pipes between concrete sections.

Preparatory stage

Installation of a septic tank is carried out in compliance with all sanitary, building rules and regulations. They think over the design of the treatment plant, the location on a private site and coordinate the plan with the relevant authorities. They decide which septic tank is better to install so that the sewerage system in a private house is made as comfortable as possible. Correctly calculate the volume of the septic tank and proceed to construction.

Excavation

The pit for the sewage treatment plant in a private house should be so large that nothing interferes with the installation of the rings. The bottom of the cesspools, at the installation site of the sedimentation tanks, is concreted. This prevents the ingress of untreated water into the soil.

The base for the second or subsequent chambers is made in such a way that water can go into the soil. To do this, make a filtration pad up to 1 meter deep from gravel and sand.

Advice! If, during the installation of a septic tank, the pit under the filtration well reaches the sandy layer of soil, the water will leave it as quickly and easily as possible.

The shape of the pit does not have to be round, a standard, square one is also suitable, the main thing is that the rings go into it freely. In addition, a ready-made concrete slab can be laid in a square pit at the bottom, while in a round pit you can only cement screed. At this stage of work, it is also worth remembering that if each subsequent well is located 20-30 cm lower than the previous one, the septic tank and the sewage system itself will be more functional.

Delivery and installation of reinforced concrete rings

The rings are delivered and installed by freight transport, so it is worthwhile to provide access to the construction site in advance, take into account additional economic costs and the turning radius of the crane boom, gas, telephone or electrical communications should not interfere with it.

Between themselves, the rings are usually connected with metal brackets, the joints are coated with a solution of cement and sand.

Installation of reinforced concrete rings

When all the wells are installed, holes are made in them and overflow pipes are installed, the external sewage system is connected to the treatment plant through a drain pipe entering the first tank. Pipe entry points must be sealed.

The space between the installed rings and the walls of the pit is covered with soil and carefully compacted in layers. If the septic tank is installed above the freezing level of the soil, it is insulated, otherwise the sewage system will be non-functional during the cold season.

Advice! It is better to carry out delivery and installation of concrete rings at the same time, this will save not only money, but also time. It is worthwhile to finish all the land work in advance and unload the rings, not just on the site, but immediately, performing the installation of a septic tank.

Waterproofing

Good waterproofing of a septic tank is fundamental to its proper operation. Each builder determines which sealant is best for this purpose. Usually, rubber-bitumen mastic is used to process seams, polymer mixtures are less common. For a longer operation of cesspool structures, internal waterproofing of the seams of the tank is also performed.

If the sealing is done poorly, then the ingress of untreated drains into the ground will be the lesser of the evils. The septic tanks, especially during the spring thaw, will be filled with water, and all its contents will flow out through the plumbing in the house, repeated pumping will be required.

Ventilation

An exhaust pipe up to 4 meters high above the level of the septic tank must be installed on the first tank. It is necessary so that the gases formed as a result of the fermentation of effluents can escape, and there are no unpleasant odors on the site. If possible, ventilation pipes are installed on each well.

Overlapping a septic tank

The task of overlapping is not only to close the pit, it must ensure the tightness of the containers. As a rule, cameras are covered ready reinforced concrete slabs on which there is a hole for a hatch made of cast iron or thick plastic. Then the structure is covered with a small layer of soil. Hatches on each of the wells will help monitor the condition and filling of the septic tank, and will also make it possible to periodically add a mixture of active bacteria for cesspools.

Maintenance of septic tanks

After the launch of the sewerage system in a private

The house needs to take measures that will extend the life of its operation.

• When evacuating the contents of the tank, some of the accumulated sludge is left at the bottom to ensure the normal filling of the chambers with active bacteria in the future.

• Pumping out the contents of the septic tank is carried out by sewage equipment, which takes the drains through the discharge pipe.

• There are also biological methods cleaning, the use of so-called bacteria for septic tanks and cesspools. They will help to significantly reduce the amount of sediment, and, consequently, pumping out the liquid will be required less frequently.

• It is categorically not recommended to lower rags, matches, napkins, hygiene products and even toilet paper into the sewer