Electric underfloor heating is becoming more and more popular. The choice of models is very diverse. These systems can be installed both in private houses and in city apartments, both in standard rooms and in cold ones, for example, on balconies and loggias. For their installation, it is not required to obtain permission from the administrative authorities of the housing and communal services. When using electric underfloor heating, there is no risk of flooding neighbors and it is easier to control heating. They are environmentally friendly, and it is quite simple to mount such systems, besides, their service life is much longer than water ones. But there are so many! How to choose the right underfloor heating and not make a mistake in choosing? We have collected all the most important and interesting information about warm floors which will make your choice easier.

The main types of electric underfloor heating

- Film

- Rod

- Cable

According to the installation method:

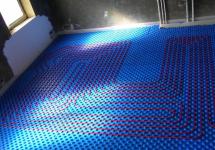

- In screed, tile adhesive. We are talking about cable and rod systems. Their installation is carried out in a layer of screed or tile adhesive, which is possible only during a major overhaul.

- Without screed (immediately under the floor covering), which does not require mortar bonding. This installation technology refers to film heating systems. The film heat-insulated floor keeps within under a finishing floor covering that is convenient at redecoration.

Differences between convection and infrared heating principles

Consider the principle of operation of a cable underfloor heating (for example, CALEO SUPERMAT). It consists in the following - when the cable is heated, the screed is gradually heated, from which the floor covering is heated. From floor covering the air temperature starts to rise. Then the warm air rises and, cooling down, falls back to the floor, after which this cycle repeats. So, thanks to convection, the room warms up evenly. With this type of heating, the human body and objects in the room are heated a second time - precisely from warm air.

In the case of infrared film floors (for example, CALEO PLATINUM), the thermal film is mounted without a screed, immediately under the floor covering on any flat surface. You don't even have to remove the old flooring. Infrared heat first heats the floor, the person and the interior elements. And then they warm up the air. With this principle of heating, it is not necessary to waste energy on heating the screed and air, and the heating rate is much higher. The average room warms up in just a few minutes. The temperature in such a room will be on average 4 °C lower than with cable underfloor heating. And the most interesting - energy savings will be up to 60%.

Floor Compatibility

The ideal option for cable and rod floors is tile and porcelain stoneware. Laminate is also suitable, but not wood flooring.

Films are compatible with laminate, parquet, carpet, linoleum, as well as wood up to 2 cm thick. It is forbidden to lay them under the tile.

In addition, it is impossible to lay any warm floors under heat-insulating materials: based on cork and containing wool. Manufacturers of block parquet also prohibit the use of underfloor heating.

What else do you need to know

Film floors are characterized by exceptional speed and ease of installation. We are used to the fact that the heating cables of the “warm floor” need to be immersed in a concrete screed. This is a laborious process that takes a lot of time, and it takes a long time to wait for the solution to dry in order to put the equipment into operation. Another caveat - often the screed has a different thickness throughout the floor due to the height difference. For this reason, floor heating is uneven.

So, when laying a film system under a laminate, carpet, linoleum and any similar coating, a screed is not required. It is only necessary to lay a heat-reflecting material, on top of it - a thermal film, connect it to the network and lay the finish coat. The heating season can be opened immediately after the completion of work, which is a big plus for owners.

Note that with “dry” laying, the system practically does not affect the height of the floor, since the thickness of the heating film does not exceed 0.4 mm.

Benefits of each system

Now that we have dealt with the types of underfloor heating and installation features, we can highlight the main advantages of heating systems and determine which underfloor heating to choose.

Advantages of cable systems

- Suitable for complex room configurations.

- High resistance to deformation and damage.

- Accumulate heat for a long time.

Benefits of underfloor heating

- The possibility of arranging any furniture.

- More economical than cable floors up to 60%.

- Versatility of installation (in screed and tile adhesive).

- Increased reliability due to the parallel connection of the rods.

Advantages of underfloor heating systems

- Quick and easy installation (installation in 2 hours for a normal room).

- Can be turned on immediately after installation is complete.

- Savings due to the principle of heating up to 20% compared to cable floors. The self-adjusting film CALEO PLATINUM saves up to 60%.

- They do not dry the air, as they heat the human body and interior items.

If you are planning a redecoration and intend to install a laminate, carpet or linoleum, then it is not rational to spend money on a screed. Therefore, film underfloor heating would be an ideal choice. They do not eat up the height of the floor, are quickly mounted and immediately ready for use!

If you decide to venture overhaul and want to lay a tile, then good option there will be cable and rod systems mounted in screed or tile adhesive.

If you do not know in advance the arrangement of furniture, then rod is preferable.

Both underfloor heating and mobile phones today can be afforded by people with not very high incomes. Why? This fact is not difficult to explain, because these goods have become much more diverse, that is, they have become cheaper. And which one to choose if there are many options on the market? And what are the considerations in doing so? The answers to these important questions will be covered in our publication: we will tell you all the subtleties and nuances so that you make the right choice, taking into account the wishes and specific conditions of housing.

By the way, the very first variants of underfloor heating were bulky structures that heated the room due to the movement of hot air. And now everything has changed dramatically, because electricity and water, which is located in special tubes, are responsible for heating. Let's take a look at the assortment and decide which warm floor is better?

The water system is a good invention of mankind

We would like to note that it is most effective to equip such heating on an area of more than 30 m2, since then it is characterized by low operating costs. A water floor is best suited for private houses with autonomous boilers. Why is it undesirable to install it in an apartment? The bottom line is that there is a significant change in hydraulic resistance.

Before pouring the floor with mortar, it is necessary to check the tightness of the pipes

Considering the theory, it should be said that this system functions due to the heating of the water circulating through the pipes. In this case, the installation of heating is carried out under concrete screed and the temperature is controlled by thermostats.

And now it is necessary to list the main advantages of water heated floors:

- although the initial costs are high, but over a large area, the savings in electricity consumption is 15%;

- when laying pipes, the location of the furniture is not taken into account;

- fire safety;

- use as the main and alternative system;

- long service life - it all depends on specifications pipes (they should not become clogged and “overgrown”);

- there is nothing to worry about if the electricity is turned off in the house - the water floor will then give off heat to the room, but only if the boiler can function in a de-energized state.

Well, as for the shortcomings, let's name the following: expensive installation, the need to comply with many technical issues.

You may also find it useful material, which provides instructions for calculating a water-heated floor:.

Electrical system - reliable heat courier

Electric heating is most suitable for baths, bathrooms, kitchens, because then its installation is cheaper than water heating. In addition, it is more expedient to do such a system in a new apartment, especially if finishing work has not yet begun.

When answering the question, what is the best underfloor heating, you need to know that according to the type of heating, the electrical system is “normal” and infrared. In the first case, a floor based on a heating cable is meant, and in the second we are talking about film floors. Of course, each species is characterized by its own characteristics, which need to be discussed in more detail.

Self-regulating cable - an example of technological progress

Everyone knows that a warm floor consists of a cable laid in the form of a "snake" and a thermostat.

According to the principle of operation, heating cables can be different, but self-regulating is unrivaled. It is made on the basis of a polymer matrix and boasts a lot of advantages:

- reliability - the possibility of overheating is completely excluded, a coupling is not used;

versatility - this type of cable can be safely laid under natural floor coverings.

Such a cable has an excellent operational property - it can be cut into pieces of any length

Heating mat - easy installation and low price

That's right, since heating mats, in comparison with the cable, are cheaper and are produced in rolls on a self-adhesive basis.

The heating mat can be laid on the old tiles

Initially, they were developed for situations where it is impossible to arrange a multi-layered “pie” characteristic of a cable system in some room. For this reason, their main areas of application are kitchens, bathrooms, toilets, in which ceramic material is used as a floor covering.

It is worth paying attention: the heating mat is produced specifically for those rooms where it is impossible to raise the floor level by more than 0.6-1 cm (not counting the finish coating).

It should also be emphasized that the mesh is easily cut into fragments (without violating the integrity of the cable) and laid out on areas of any configuration.

Film underfloor heating - comfort and healthy heating

When deciding which are the best underfloor heating, it is necessary to consider a thermal film consisting of carbon strips interconnected by a copper bus and special contacts. All heating elements in it are laminated on both sides with electrotechnical polyester, which provides water resistance and a high degree of protection.

When laying a film floor under porcelain stoneware, parquet, heat-reflecting material with a solid layer should be used

And where are infrared floors used? Firstly, they are widely used for heating rooms without stationary heating, as well as in any premises during the off-season, when the batteries are turned off. Secondly, this floor can heat the ceiling and walls.

This is important to know: film systems are in demand not only in houses and apartments, but also in kindergartens, hotels, hospitals, that is, at all facilities where “healthy heat” is required.

In a word, an infrared floor is a good solution, because we are talking about many advantages: ease of installation, cost-effectiveness, flexibility, mobility, resistance to mechanical damage, safety.

Criteria for rational choice - what to look for?

Undoubtedly, the choice of underfloor heating is a responsible process, therefore, when choosing the right system, certain rules must be followed. First you need to decide whether the heating system will be the main or auxiliary. The following points are taken into account here:

- features of the premises, its characteristics;

- properties of electrical wiring - the bottom line is that engineering systems must withstand voltage;

- type of flooring;

- Do you need "smart" management?

In addition to these parameters, complex calculations are made, which take into account the number of storeys of the room, the presence of rooms with large glazing areas (balcony, winter garden).

This is important to know: the calculation of the power of the system directly depends on the level of humidity and temperature in the room, as well as on the thickness of the "warm floor" system.

I wonder which company to choose a warm floor? This fundamental question is also of great concern to people and is not considered the last. Naturally, it is better to give preference to a well-known manufacturer, because then you can be sure of the quality of the products. Alternatively, the following companies are popular: Ceilhit (Spain), Nexans (Norway), Ensto (Finland). These manufacturers provide consumers with a guarantee and offer flawlessly working devices.

Yes, quite recently, underfloor heating was the privilege of exceptionally wealthy citizens, but today they are available to almost everyone. And this is wonderful, because all people should enjoy the benefits of civilization and live in a modern way!

When choosing a system for organizing the main or additional heating of their home, the owners of the premises ask themselves: “How to choose warm electric floors?”. It will help you find out the answer simple tips and detailed manufacturer reviews.

Underfloor heating systems are gaining more and more popularity. From an auxiliary solution for improving the comfort of apartments, they have become a full-fledged source of heating for suburban real estate. Heating elements are modernized and improved every year. Manufacturers offer customers more and more different powerful heating solutions, which are becoming more and more difficult to navigate. How to choose the optimal heating design for your needs?

Benefits of electric underfloor heating

- Design versatility. Possibility of use in residential and non-residential buildings as both auxiliary and main source of heating.

- They don't spoil. All structural elements are hidden from prying eyes, do not violate the integrity and aesthetics of the interior.

- Temperature control accuracy. With the help of a thermostat, you can control the temperature in the room with an accuracy of 0.1 degrees.

- Ease of installation. Some types of systems can be installed independently without the help of specialists.

- Durability. Subject to the rules of operation, electric heating systems will last for decades.

Electric underfloor heating: a system that stands out for its durability

- Uniform heating. Heat is distributed evenly on the surface, which allows you to fully warm up the room.

- Possibility of partial repair. In the event of an underfloor heating failure, only the damaged area can be replaced without affecting the integrity of other structural elements.

- Lack of additional equipment. Unlike a water floor, which will require the installation of a boiler, an electric floor will not require any auxiliary devices.

- Application safety. The temperature of the heating element does not exceed the limits that are comfortable and safe for humans, which eliminates the possibility of burns.

Types of electric floors depending on the type of heating element

According to the type of heating element used, the following types of electric floor systems are distinguished:

- Film. The film layer serves as the basic heating element. Installation of this design requires a minimum of effort - the film fits under any modern floor covering, pouring cement screed is not required. Suitable for use under laminate, parquet, linoleum. It is only important to observe temperature regime recommended by the manufacturer for each finishing material. Popular are 2 options for the execution of a warm floor:

- Carbon film. Lavsan film, between the two layers of which a grid of resistive material is laid. It is produced in ready-made rolls, which can be cut into sheets of suitable size. Radiate heat, mainly consisting of infrared waves. Such heaters warm the room and have a beneficial effect on the entire human body, healing it. The disadvantages of the system are its high cost and the likelihood of overheating in areas with installed furniture and appliances.

- Bimetallic heaters. 2-layer construction - aluminum alloy and copper alloy. They also emit infrared waves and are produced in the form of rolls divided into small sections. Suitable for arranging floors of a floating type, they are not mounted in a layer of tile mix or cement.

- Heating mats. The heating mat is a thin cable laid in a snake on a nylon mesh. Finished products are equipped with a thermostat and are completely ready for installation. The canvas can be easily cut into pieces of suitable sizes, which allows the system to be used in rooms of any shape and size. It is possible to organize a warm floor from mats at any stage of construction, even when the floor level has already been raised, the heating elements are very thin and do not require a layer of cement.

Scheme of installation of underfloor heating mats: even a beginner can handle installation

Mounting the structure is extremely simple - even an inexperienced specialist will cope with the task. The mat can be laid directly under the laminate "dry" or under the tiles, having previously applied a thin layer of special adhesive to it. The disadvantages of the systems include their rather high cost and the possibility of using them exclusively as an additional, not the main, source of heating.

- Cable. The basis of the design is a single or two-core cable. It is laid with a snake on the metal base of the mounting structure and covered with a layer cement screed. Differs in lower cost in comparison with heating mats. The cable is laid with different pitches, ensuring that a certain temperature is maintained even in cold rooms.

The arrangement of a system from a cable of standard thickness requires a mandatory screed layer of at least 3 cm, so such floors warm up longer. A thin cable does not require the arrangement of a cement layer, it combines the advantages of heating mats and cable systems. A professional and careful approach to installation is required.

Advice. When choosing a suitable system, taking into account the cost criterion, calculate not only the price of the floor itself, but also the costs of its installation and pouring the building screed (if the design requires it).

Underfloor heating cable construction: a solution with many advantages, but demanding on installation

How to choose the right electric floor heating

To determine the right underfloor heating system for your home, evaluate the following selection criteria:

- Energy consumption. Each of the types of electric floor elements converts electrical energy into a thermal one with a very high efficiency, almost one to one. However, despite the efficiency declared by the manufacturer, the degree of insulation of your room should also be taken into account. In houses with thin cold walls, heat loss will be very significant, so energy consumption increases in proportion to the increase in the number of on / off cycles. In this case, it is worth choosing the most expensive and powerful systems that will pay for themselves during operation.

- Appointment. For standard rooms in insulated buildings with a screed, cable floors are suitable; for bathrooms, it is preferable to use rod heating systems. In rooms where the screed is not planned to be poured, it is advisable to install film floors.

- Reliability and durability. Cable systems are recognized as the most durable; leading manufacturers guarantee up to 20 years of uninterrupted operation. Rod and film floors have not yet been sufficiently tested, as they are relatively new products on the construction market.

- Price. You should not choose the cheapest solution, because you buy a system for many years. In the event of its failure, it will be necessary to violate the integrity of the floor covering, spend money on Construction Materials and replacement of failed heating elements. It is better to immediately trust trusted manufacturers. The floors of the brands REHAU, DEVI, CALEO, UNIMAT and affordable solutions from Teplolux are popular.

Choosing a warm floor should be based on the type of room, manufacturer and energy consumption of the device

Above are the main important nuances to which you should pay attention when buying a warm floor. Of course, there are individual cases, however, most often, the listed characteristics are enough for the coating corresponding to them to serve for many years.

Advice. By purchasing systems from trusted manufacturers, you get not only a guarantee of quality, but also the opportunity to take advantage of service repairs and maintenance.

Modern floor heating systems can completely replace the usual risers and batteries. Over time, more and more powerful and easy-to-install structures appear that change the usual ideas about the organization of heating in an apartment and a house.

Video: How to choose an electric underfloor heating

Electric underfloor heating is popular due to its ease of installation and durability. It also does not require any additional communications other than electricity, therefore it is successfully used in private construction. It is not difficult to make an electric underfloor heating, its installation does not require special knowledge and takes a little time. Consider the main stages and important nuances that you need to know when installing a warm floor.

Electric underfloor heating is successfully used in absolutely any type of premises. It can be apartment or private houses, garages, baths or loggias. It is only important to choose the right system power and provide sufficient thermal insulation. This method can be used as the only source of space heating. But electricity costs can skyrocket.

Types of electric floor heating (ETP)

All options for organizing such systems are divided into three groups.

- ETP based on heating wire. The whole system is a thermostat, a temperature sensor and a long wire in double insulation, which produces heat. This is the cheapest, but also the most time-consuming option. The wire must be laid out on the base floor and fixed in a special mounting tape. It is important to maintain the same distance between the turns of the wire and avoid kinks and overlaps of the wire.

- ETP based on heating mats. This option is more convenient in installation, since the wire is factory-packed into special reinforcing mats and rigidly fixed in them. You do not need to worry about laying the wire, just lay out the mats of the required power on the base and connect them. This saves a lot of time and reduces the risk of error.

- ETP based on infrared film. This option is fundamentally different from the previous two. Heating occurs due to infrared treatment of the carbon material deposited on the film base. This option does not require the mandatory use of a cement screed, the finish coat can be laid directly on top of the film. However, this is the least reliable and uneconomical ETP option.

Comparative characteristics of cable and film underfloor heating

| signs | Film heating | Cable heating |

|---|---|---|

| Utility room | No need | No need |

| Floor thickness with screed | 5-10 mm | 50-100 mm |

| Installation time | 1 day | 1 day |

| Ready for use | Straightaway | 28 days |

| Installation options | Floor, ceiling, walls, any surface | Floor. Mounting on other surfaces is possible, but difficult |

| Reliability | If even a significant part of the system is damaged, undamaged segments continue to work | With any damage to the cable, it completely fails. |

| Repair costs | Minimum | High, 100% |

| Service | Not required | Not required |

| Freezing in winter | Absent | Absent |

| Health impact | Positive healing | Neutral, subject to high-quality two-core cable |

| Heat distribution and effects on coatings | Uniform heating | Uneven temperature distribution, there are zones of elevated temperature |

| Zoning | Possibility of organizing separate point zones | |

| Expenses | Relatively low initially. energy saving | Relatively low initial, operational - by counter |

The principle of operation of the ETP

In the case of a heating wire and mats, the conductor is heated under the action of an electric current flowing in it. The wire heats the screed, which in turn heats the finish. Heating occurs by convection.

In the case of using an infrared film, heating occurs by thermal radiation of the carbon layer, which occurs under the influence of an electric current. This radiation heats the finish and objects that are close enough to the floor. From them, by convection, the air in the room is heated.

Temperature control is carried out using a temperature sensor and a thermostat, through which a warm floor is connected.

How to choose the required power of a warm floor

Before calculating the power, you need to know whether the room will be heated only with the help of the ETP or whether it will complement the main heating system, creating additional comfort. Each ETP manufacturer in the technical data sheet of his product indicates what power should be selected in each case.

For most premises, a value of 120-140 W/m2 is selected as a comfortable ETP based on a heating wire or a heating mat. If the ETP is made on the basis of an infrared film, then the comfortable value is 150 W/m2.

If the room will be heated only by the ETP, then for the heating wire or mat, the value of 160-180 W / m2 is selected, and for the infrared film, the power should be equal to 220 W / m2.

If you are using a heating mat or infrared film, then the capacity per square meter is known in advance and you just need to choose the appropriate option. In the case of using a heating cable, the power will depend on the distance between its turns. You need to know in advance the area and shape of the heating surface, after which you will determine the required distance from the tables in the technical data sheet or instructions. Usually it is 10-30 cm, depending on the power of the cable.

It is important to take into account the maximum possible load on the building's electrical network, as well as to use switching equipment designed for the appropriate load current.

What are the consequences of errors in the installation of ETP

A common mistake is to lay the ETP under massive furniture and household appliances. Insufficient cooling of the floor surface can cause the wire to overheat and fail.

Never turn on heating wires or mats until the screed is completely dry. Even short-term activation can lead to damage to the heater. Checking the integrity of the laid cable and the correct connection is possible only by measuring the resistance. This does not apply to the infrared film floor, it can and should be included in the network for verification.

Do not kink or step on the wire, and avoid pulling on the wire. All this can lead to damage to the conductor or insulation and breakage of the entire system. Also avoid damage to the heating film if you are installing an infrared ETP.

Do not forget to control the insulation resistance at all stages of work, especially before pouring the screed. The value should not differ from the one declared by the manufacturer by more than 10%. If you see a strong discrepancy in the values, stop work and find the area of \u200b\u200bdamaged insulation. If this rule is neglected, then after the screed has dried, a very unpleasant surprise may await you in the form of a non-working ETP.

Do not pour the temperature sensor directly into the screed. Place it in the corrugation, which will be filled with a screed. Sensors often fail and if you pour it into the screed, then replacing it will require considerable effort.

When installing an infrared ETP, do not forget to isolate the current-carrying parts at the places where the film is cut. Otherwise, the protective equipment will constantly detect the leakage current and turn off the power to your ETP.

Advantages and disadvantages of ETP

The advantages of ETP are:

- ease of assembly design. This is especially true for heating mats and infrared film. It is enough to simply spread them on the base and connect according to the instructions, this does not require any special knowledge;

- high reliability and durability. Provided that the insulation is intact, the heating wire or mats cast into the screed have an almost unlimited service life;

- high autonomy. ETP does not require the house to be connected to the water supply and even works from an electric generator. This allows you to use it in village houses and cottages.

The disadvantages of this heating method include:

- relatively high cost of space heating. ETP consumes quite a lot of power, especially if it is the only heating method;

- due to the relatively low temperature of the floor surface, the air in the room warms up rather slowly. This is relevant if the ETP is the only source of heat and does not work constantly. For example, in country house in winter;

- since it is forbidden to place heating elements under massive furniture, after the completion of work, a global rearrangement of furniture will not be possible.

Step-by-step instructions for installing ETP

Foundation preparation

The ETP floor must be laid on a clean, dry base. It is necessary to cut a groove in the wall for the temperature controller and wires. Carefully sweep away any resulting debris.

After that, you need to put a layer of thermal insulation on the base, for example, penofol or expanded polystyrene. If there is a heated room one floor below, then it will be enough to put a layer of penofol 5 mm thick. If under a warm floor unheated room or soil, then it is necessary to use expanded polystyrene with a thickness of 20 mm to 50 mm, depending on the severity of winters in your area. Thermal insulation is fixed with any adhesive material.

Laying heating elements

Mark the floor before starting installation. It is important to highlight those areas that should not warm up. It is important to remember that a distance of 0.5 m must be kept to walls and large furniture, and a distance of at least 0.3 m to heaters, stoves and fireplaces.

If you are installing a warm floor based on a heating wire, then first you need to install a mounting tape. It will fix the turns of the wire and prevent them from shifting. Lay the tape on the thermal insulation and secure with dowels.

Mounting tape fastening

Carefully unwind the heating wire and lay it over the thermal insulation and mounting tape, strictly observing the parallelism of the turns and the gaps between them. Secure each turn with fixing antennae on the mounting tape. In no case should the wire coils overlap. After laying, measure the insulation resistance, it should not differ from the norm by more than 10%.

If you are using infrared film, then carefully unwind it along the base, then connect the sheets of film together in parallel. Lead the wires to the installation site of the thermostat.

Temperature sensor installation

If you are mounting an ETP based on a heating wire or mat, then the temperature sensor must be located in a corrugated tube. Make a small recess in the heat-insulating layer and put a 20 mm tube into it. Plug one end of the tube tightly with insulation, and bring the other end above the floor level in the same place where the wires will come out.

Place the temperature probe at the end of the tube and make sure it can be easily pulled back out. This is important for the possibility of replacing the sensor after the floor is filled with screed.

If you are using an infrared ETP, then you can check it by turning it on, the floor should be warm to the touch.

Filling the warm floor with a screed

If you use an infrared ETP, then pouring is not required, you can immediately proceed with the installation of the finish coating.

If you use a heating wire or mat, then pouring the screed is strictly required. It is necessary to fill cement to a thickness of 30-50 mm. After the screed has hardened, you can proceed with the installation of the finish coating, for example, tiles, laminate or linoleum. The first inclusion of a warm floor can be carried out only after the screed is completely dry. Most manufacturers set a complete drying time of 28 days. This ensures that there are no voids around the wire that will burn out the wire over time.

Video - Installation of heating mats

Video - Underfloor heating under tiles

Video - Installation of Electrolux underfloor heating, cable

Video - Installation of film underfloor heating

An electric underfloor heating is used as an additional source of heat. This scheme works well on floors of any kind and is arranged in houses made of any material. A distinctive feature is simple installation, which will appeal to an inexperienced master. It is good to mount such a floor in rooms where it is very difficult to lay a heating system. For example, a balcony or terrace. Sometimes, underfloor heating is used as the only heating method, in which case it is necessary to take into account the upcoming energy costs.

Benefits of electric floors

Electric floor heating has a number of advantages, due to which it is often used in an apartment or a private house.

- Possibility of heating the whole room, as well as a separate part of it. Warm floors can be laid over the entire area of the room, or you can install it only in a certain part. In this case, space zoning is performed.

- Electric warm floors are convenient to use, since they are controlled by a remote control or a temperature controller is used.

- It is possible to connect to the system smart House". In this case, the heating can be controlled remotely.

- Simple and easy installation that does not require special tools.

- No possibility of leakage.

During installation, the floor occupies no a large number of the height of the room, and therefore it must be used where this moment will not have a negative impact

Such floors are easier to use in high-rise buildings, since the standard water heating method puts a greater load on the floors, and the electric warm floor weighs several times less.

Warm floor

Warm floor But it should not be noted that such a coating also has disadvantages.

Disadvantages of electric floors

These include:

- Possibility of a short circuit - this problem can occur with any electrically heated device and a warm floor is no exception. This problem should be prevented by checking all cables before laying the flooring.

- Energy costs are not so much a problem as a disadvantage. When using such a scheme, an increase in costs cannot be avoided - the decision depends on what use is envisaged:

- If electric floor heating is used as a permanent power source, then it makes sense for reliable home insulation. For example, to make high-quality thermal insulation of walls. In this case, heat losses will decrease and, as a result, heating costs will also decrease.

- If the system is used as an additional source of heat, then it makes sense to lay the elements where there is the most movement. As a rule, the most frequent movement is carried out in the center of the room, respectively, and the heating elements must be laid in the center. Thus, fewer elements will be required, and costs will be reduced by heating a certain area of \u200b\u200bthe room, and not all at once.

Sometimes radiation is singled out as disadvantages. But the fact is that such a system does not differ from another electronic device, and therefore you should not be afraid of harm from it.

Types of electric heating

On the market for electric underfloor heating, you can find several versions. Each has its own pros and cons. In order to understand which option is best suited to a particular housing, it is necessary to study each of them.

Electric underfloor heating is divided into 2 types by action:

- Resistive - heating in this type of heating is carried out by cables.

- Infrared - heating is carried out due to a special component that transfers heat to surrounding things.

Cable electric floor

The cable version is different in that it uses cables to match the quality of the heating elements. Connected to electricity, they heat up due to which the surface is heated.

Solid wires

Cables with one core are both a conductor of heat and a heating element. If the installation of electric underfloor heating occurs with such a cable, then it is important that the ends of the wire converge in one place. This is necessary to connect the system to the control unit.

Two-core wires

Two-core wires are much more convenient in terms of use. One core is needed for heating, the other closes the circuit. When using these cables, the meeting of the two ends is not necessary. Therefore, it is more often used, it is much easier to bring one end of the wire to the control unit than to mount the system so that both ends meet in one place.

heating mat

The convenience of mats is that you do not need to independently calculate the necessary power, this was all done by the manufacturer. Mats are bought depending on the number square meters to which the heating element is to be mounted.

Infrared heating types

Rod type of heating

A kind of infrared floors is a rod electric warm floor. It resembles a rope ladder with wooden or metal rungs. But a rod with a heating element is used as crossbars.

Underfloor heating is provided by this rod. And as a "rope" a polymer is used that can be cut to carry out the installation. However, the cut polymer will need to be fixed into the circuit, as it plays the role of a conductor.

Film type of heating

Electric floor heating can also have a film look. In this case, the heating of surfaces occurs due to infrared radiation. The elements responsible for heating transmit a thermal signal over short distances, heating what is next to them. These elements are made of carbon paste, and copper wires, which are enclosed in a film, are responsible for heating it. For laying, the film version is most often used, since it is easy to install.

Film option

Film option The film floor has a very small thickness, and therefore it can also be used where ceilings have a limited height.

Thermal sensor for electric floor

If you decide to install electric underfloor heating in the house, then you need to thoroughly prepare for this. In addition to materials such as concrete, flooring and other building materials, you need to purchase the right set of underfloor heating and additional elements that will control the system.

These elements are:

- Temperature sensor - it shows the temperature data.

- Thermostat - it is necessary to set the temperature to which the element will heat up.

Both of these elements work in pairs, as soon as the temperature sensor detects the temperature to which the elements have heated up, the thermostat receives a command and turns off further heating.

Modern thermostats can be equipped with various parts that allow you to mount an electronic underfloor heating. In this option, you can set the heating and shutdown temperature, and the data can be stored once, further control will be taken over by the thermostat system.

heat sensor

heat sensor In new models of the device, control can be carried out remotely by installing a SIM card. That is, in fact, the control sensor is transferred to the phone.

By means of an SMS message, you can set the time to turn on and turn on the heating, the temperature of the floor heating.

Also, you can turn off the entire system, if necessary.

Calculation of the power of underfloor heating

Before choosing a warm floor, it is necessary to calculate the area of \u200b\u200bthe room and the power of the system, so that it can heat the home. First you need to decide on the mode in which the heated floor from electricity will be used. If the floor will be the main source of heat, then a complex calculation scheme is used. If the floor is used as an additional source, then the calculations in this case are much simpler.

When using a warm floor as the main heating system, an accurate technological calculation is needed, which should take into account such points as the area of \u200b\u200bthe house, the number of doors and windows, and possible heat losses. At the same time, when the area is calculated, you need to pay attention to the furniture that will be placed in the room. Warm floors must be laid on those spaces that are free from furniture.

An exception to this condition is the heating rod elements. They can be laid over the entire area, as they are self-adjusting.

When calculating, it is important to correctly calculate the possible heat loss. Close attention should be paid to these data, since incorrect calculations will lead to the fact that such a system simply will not be able to cope with the heating of the room and the house will be cold. Possible heat losses are calculated using special tables. It is best to entrust these calculations to specialists. They will more accurately calculate the required power of the system.

If the electric floor heating will be used as an additional source of heat, then the necessary calculations can be made independently. In this calculation, it is necessary to take into account the type of floor used, resistive or infrared, the laying area, that is, the area on which the heating elements will be located and the power of the wire.

Laying rules

Before you start laying floors, you must familiarize yourself with the laying rules. It is necessary to strictly follow the instructions, then you can guarantee the correct and accurate operation of the entire system.

These requirements include the following:

- Before laying, it is necessary to install a thermally insulating layer. This is necessary for all types of floors, as part of the heat energy will not go down. In this case, heat loss will be minimal, and floor heating will also occur faster. In this way, electricity costs can be reduced.

- When placing floors, the location of furniture must be taken into account, heating elements cannot be placed under them, except for rod floors.

- From the walls there should be indents of 5 cm, and from heaters (batteries) at least 10 cm.

- When laying, it is necessary to observe the wire pitch, and also not to allow the wires to cross.

- During installation, it is important to ensure that there are as few cuts for turns as possible. Thus, the integrity of the system is not violated. All incisions must be carefully insulated. If this rule is not observed, power is lost, and there is also the possibility of a short circuit.

- Connections of small pieces of the floor are also undesirable, the minimum section length should be at least 50 cm. When buying a warm floor, it is better to take it with a margin.

It is imperative to install an RCD device, it will turn off the heat supply in case of problems. For example, if power is lost, the RCD will disconnect the system from electricity.

All floor installation work is best left to a professional electrician.

Also, for electric floor heating, it is better to allocate a separate line where only this system will be connected. Also, it is better to bring the system to a separate machine, in case of problems with electricity or the floor itself, you can de-energize the system with this device.

Installation of a warm electric floor

Before choosing electric underfloor heating, it is better to clarify what kind of flooring is planned to be laid and how the base for the underfloor heating will be prepared. Already depending on these data and buy a floor heating system.

There are three ways to mount the floor:

- Screed installation.

- Mounting on a screed, but fixing with tiles.

- Installation under flooring, but not under tiles.

If it is necessary to install an electric underfloor heating in a screed or under a tile, then you will have to choose cable systems or rod floors.

Laying the film floor is only allowed under the floor covering. Moisture damages this floor. Therefore, it is desirable to lay it in rooms, and not in sanitary facilities.

The installation itself is almost the same:

- A layout plan is drawn up, taking into account the location of furniture and indents. The plan is best done on graph paper with respect to scale.

- A layer of waterproofing and a layer of insulation are laid, if necessary.

- The markup is transferred to the prepared base.

- According to the markup, the floor is laid. All places that are cut, if necessary, must be insulated. Also, the position of the temperature sensor and thermostat is determined. The latter is installed on the wall and from the place of its installation it is necessary to lower the strobe to the floor.

- After laying all the elements, check the resistance.

- A pipe is laid in the strobe, one end of which is connected to a thermostat, and the other end contains a temperature sensor. The end of the pipe with the temperature sensor is placed in the middle of the nearest heating elements.

Electric heating layer cake

Electric heating layer cake Verification work

After these works have been carried out, it is necessary to check the operability of the sensor and the thermostat, once again the resistance and the system are completely de-energized, and the regulator is removed. Then, the screed is poured, the tiles or flooring are laid. Moreover, if a screed is planned, then first they wait for the concrete to dry, then they check the performance of the system again, and then they mount the floor covering.

It is worth checking how the temperature sensor is removed from the pipe, this is necessary so that later it can be replaced without problems if necessary.

Energy saving

The electric floor heating system has its pros and cons, which are described above. But, with proper design and use, this system will cause only positive emotions. Do not be afraid of a large consumption of electricity, and, as a result, an increase in payments. With a reasonable approach to use, the number of kilowatts will not increase much, and the heat in the house will be constant. This effect is achieved by using the floor only during hours when someone is at home.

Also, it will not be superfluous to think over the insulation of problem areas: doors, windows, balconies. Thus, it is possible to minimize heat loss, respectively, and the system itself will not work at full capacity. The effect of the work done can be seen on the heating bills.