Metal crafts with or without welding are best suited for decorating a private home or country cottage. Choosing a technology for creating such products requires taking into account your skills and abilities. In addition, we should not forget about certain financial expenses for the purchase or manufacture of special tools.

A little history

The history of homemade metal products goes back more than a thousand years. Gradually, such crafts turned into one of the areas of artistic art. And from the beginning of the 11th century they became an obligatory attribute of European architecture.

In our time, their popularity has not faded. Despite the high cost, beautiful handmade metal crafts remain loved by both interior designers and ordinary people, as they are a great way to add uniqueness and originality to a setting.

Techniques for creating decorative items from metal

Hand-made metal products will add attractiveness to any type of structure, from cornices to furniture. As you can see in the photo of metal crafts, there are the following techniques for their manufacture:

- casting;

- difovka;

- forging;

- bending;

- stamping;

- cutting;

- filigree;

- coinage.

The last six are the most common. The uniqueness of metal as a material lies in the fact that it can be used to create a wide variety of compositions for both interiors and exteriors.

You will be ready to realize your idea of making a creative and interesting little thing only after you choose an idea and instructions for making a craft.

The simplest forged decorative items

If you are a beginner who is just beginning to comprehend the intricacies of forging, then it is advisable for you to start by making simple metal crafts with your own hands, for example, from a box or casket.

Rat made of metal

A figurine of a rat would be a good option. To create it you will need the following materials:

- steel rods with a diameter of 4, 6, 10, 12, 14 mm;

- metal sheet 2 mm thick;

- wire;

- bearings – 3 pcs.

You should also prepare a grinder, drill, metal scissors, electric welding, and a grinding circle.

Here's a quick step-by-step guide:

- We make a head and a torso from two pieces of pipe. To do this, we cut out the required parts along the entire diameter of the pipes and weld them.

- We clean the elements with a grinder with a circle;

- We weld the rat's head to the body.

- We make sketches of the ears and paws and transfer them to a sheet of metal. Cut out the resulting blanks.

- We roll the paw blanks into a funnel, scald them and clean the seams.

- We collect the rat.

- We make paws-brushes from twigs. To do this, we connect a 4 mm rod with a 10 mm rod by welding, and the lower 6 mm with a 12 mm rod. Then insert into funnels and scald.

- We make a tail from a 14 mm rod and attach it to the rat.

- We make a hole for the eyes, insert bearings into them and weld them. The third bearing should be used to create the spout.

- We drill holes for the mustache and insert the wire into them.

- We clean everything with a grinder and make fur. To do this, it is necessary to apply longitudinal welds close to each other.

- We coat the finished rat with varnish.

Panel "Fish"

Let's consider one of the popular children's metal crafts with manufacturing - the “Fish” panel. To create it you need to prepare wire of different thicknesses, beads, beads, paper, scissors and a pencil.

Here is a small master class:

- Draw a sketch of a fish.

- Accordingly, we make a wire frame with curves.

- We construct jumpers from thin wire.

- We fill the body of the fish with beads and beads. To do this, we attach a wire to the curves on the frame and string decorative material onto it. Then we fix it on the back side of the panel. Beads are used to highlight large scales and eyes.

- In this way we gradually fill the entire fish. Its color depends on the color of the beads.

The finished image can be used to decorate a corridor wall or a child’s room. This panel is a wonderful gift for a fisherman.

In conclusion, we note that making metal crafts looks complicated only at first glance. In fact, anyone can make them. Therefore, do not be afraid - try, experiment. And perhaps a real work of art will come out of your hands.

Photos of metal crafts

Note!

Note!

Note!

Every person strives to decorate their home. For this purpose, some buy various decorative items in stores, others make figures from scrap materials with their own hands. Made from wood, glass or metal, crafts occupy a worthy place in the home and attract with their originality.

Making metal decorative jewelry

Nowadays, many people make their own decorative elements. Why spend money on purchasing ready-made jewelry if you can make it yourself from scrap materials? Of course, working with metal requires certain skills and knowledge, so it is recommended to start by creating simple shapes.

To learn how to make crafts from metal, you will need to master the techniques of working with welding equipment. Welding is the best way to fasten metal parts together. If you don't have a welding machine, you can purchase one from a hardware store or ask a neighbor. You will still need electrodes to work.

Material for your creations can be found in the garage among unnecessary spare parts and sheets of metal. Those who constantly create decorative jewelry from iron even visit landfills in search of suitable parts. Thanks to the hands of masters, already obsolete designs take on a new life, being embodied in beautiful figurines and sculptures. Moreover, such material is obtained completely free of charge.

Metal crafts

Iron is a durable material that is used in a huge number of structures.

You can make many useful things from it, for example, a table and a bench for a summer house, a barbecue, a stove, as well as original figurines that will decorate the area. Today, landscape design, which can be supplemented with metal products, is very popular in country houses. Crafts of this kind look very harmonious on the site and evoke envious glances from neighbors.

With patience, you can bring to life the most bizarre design. You can make an iron beast or a man, a model of an airplane or a motorcycle. It all depends on your imagination. If you can’t come up with anything, you can look at ready-made metal crafts. Photos of some of them are presented in this article.

Basic safety rules

When working with metal and welding, safety precautions should be observed. You should not handle a sheet of iron without thick gloves. The material may have uneven and sharp edges that are easy to cut on.

When working with metal and welding, safety precautions should be observed. You should not handle a sheet of iron without thick gloves. The material may have uneven and sharp edges that are easy to cut on.

When starting welding, be sure to wear a mask or safety glasses. In general, it is better to work in a special suit that will protect you from sparks flying in all directions. Do not cook near flammable materials: plastic, paper, wood.

From all of the above it follows that you can make decorative metal jewelry and crafts for your home and garden with your own hands. At the same time, you will not only save on the purchase of a finished product, but also enjoy the work.

What you can do with your own hands from old scrap metal

Even in ancient times, starting from the 11th century, it became a popular craft to make handicrafts with your own hands, from scrap metal or, as they were called then, metal rocks. Gradually, this craft turned into a real art, which is now an integral historical part of architecture and ancient buildings. You will be interested in seeing sculptures made from scrap metal with your own hands.

Today, there are many types of special tools that allow you to make sophisticated cuts on a metal surface, as well as weld or solder to connect several parts of non-ferrous or ferrous scrap. Modern technologies make it possible for anyone to make a product to their liking; for this it is not necessary to have any special artistic skills. All you need is desire and perseverance. Photos and videos of such handmade crafts can be seen on our website.

Be sure to check out - DIY crafts from waste!

DIY crafts have always been in demand and were quite valuable, as they emphasize the individuality and peculiarity of their owner.

Metal is one of the most durable materials; it can be used to create garden furniture or a children's swing, as well as small jewelry, such as a ring or bracelet.

For example, steel is much cheaper than gold or silver, but has greater strength; it, like precious metals, does not lose its color and does not corrode; many individual and original things can be made from it:

- From a steel barrel, you can make a wood stove.

You can also make many useful and interesting things from waste car parts, for example,

- the valves of an internal combustion engine will make excellent jingling bells for doors,

- piston system and connecting rod mechanism, excellent table stand, it’s easy to make beautiful legs from them.

Environmental benefits

Scrap metal is thrown away every year and simply rots in the ground; instead, you can give it a second life by making some kind of craft; this is not only an interesting hobby, but also a way to protect the ecological system from dangerous elements released during the decomposition of metal in the soil.

You might also be interested in seeing:

DIY rose from a can of cola Coin medallion Some things are made of stainless steel

DIY metal products: features, types and drawings

In modern conditions, when the market is overflowing with mass-produced goods, handmade products are becoming increasingly in demand. Specialized departments and entire shops or salons are beginning to appear in cities, selling exclusive items made by master craftsmen. If you want to give someone an unusual gift, the best option would be handmade metal products, although there are many other handmade souvenirs.

Handmade exclusive

Execution techniques can be so diverse that the range of products amazes even the most experienced person. Most often, such souvenirs are purchased for interior decoration or as a gift. You can buy or order the following items:

Products can be made using the following techniques:

- decoupage;

- ceramics;

- artistic forging and casting;

- fusing;

- batik;

- Crochet;

- beading;

- embroidery.

It all depends on the imagination and technical equipment and skills of the authors. Among customers with large financial resources, metal art products are especially popular.

Areas of application

Items made using artistic casting and forging techniques are used to decorate elements in various areas of design:

- architecture;

- furniture;

- sculpture;

- cornices;

- staircase balusters;

- fireplaces, stoves, barbecues;

- costume jewelry and jewelry.

Decorative items made of metal effectively complement any interior, giving it a certain chic and luxurious style.

Types of decorations

Do you want to learn how to make metal products with your own hands? Photos of such objects fascinate with their beauty. All things look very elegant, and most importantly, they retain the warmth of the author’s hands. That is why such products are quite expensive. True connoisseurs of style are willing to pay well for something exclusive.

You can make various metal products with your own hands. The following techniques are used to process this material:

The items that can be made using these methods are very diverse. Masters do:

- bracelets;

- earrings;

- rings;

- pendants;

- belts;

- caskets;

- flowers;

- decorative vases;

- interior decorations;

- elegant plates for fruits or sweets.

Making metal products with your own hands is quite simple. The main thing is to know the stages of the process and have the necessary equipment.

Complex items require a lot of time and expensive equipment to produce, but some souvenirs can be made from almost nothing. It all depends on what you are going to do this for. If you choose artistic metal processing as a professional field, then you should be patient and realize that some financial investments will be required. To make simple but original gifts for friends, relatives and acquaintances, you only need desire and perseverance.

Manufacturing technologies

You can easily create metal products with your own hands. Photos of drawings and process stages will help you with this. Carrying out artistic work involves stages of shaping, processing and finishing. Making things, as already mentioned, occurs in different ways.

- Casting refers to the filling of a mold with a liquid alloy.

- Forging is the plastic processing of a material with a hammer, a press, as well as bending, twisting, and chopping.

- Bending is a simple type of the previous option, performed by riveting or welding parts of the product.

- Defining is a method of processing a thin, no more than 2 mm, sheet of metal with hammer blows, thanks to which it acquires the required configuration.

- Separate elements are prepared by stamping and cutting and holes are made.

- Filigree is made from twisted or smooth, sometimes flattened copper, silver, and rarely gold wire. The curved parts of the patterns are soldered.

- When minting, a relief pattern is obtained using stamps or special tools that are placed between the hammer and the product.

Drawings of metal products can be done manually or in special programs on a computer. Three-dimensional modeling allows you to make not only a regular drawing, but also to build a three-dimensional model of the future product. It makes it possible to see the appearance of a thing, including in the interior, long before its actual appearance. In this case, it is possible to adjust the parameters of the product without the material costs of re-manufacturing it.

How to make a box from an aluminum can

Even a schoolchild can make the most basic metal thing. The main thing is that this will require practically nothing except time, hard work, imagination and the desire to create. You can make a beautiful box from an ordinary soda can.

Materials and equipment

The raw materials for production, one might say, are lying under your feet on the street. You will also need the following items:

- sandpaper (skin);

- sharp scissors;

- ruler;

- pencil;

- ball pen;

- solid base no larger than A4 format (depending on the size of the box);

- sheet of paper for the diagram.

Sequencing

At the first stage, a layer of paint is removed from the can using sandpaper. It is better to do this from an unopened container, since its walls remain elastic under the influence of the contents. The process will go faster and you won't ruin the metal. If you use an empty one, be careful not to crush the can.

In the next step, you need to obtain a thin sheet of aluminum from the blank, the size of the reamer of the future box.

To do this, the can is cut and sharp and uneven edges are removed.

At the next stage, the edges and sides of the product are marked.

A thin metal sheet is placed on a solid base.

The diagram of the box can be drawn directly on a metal sheet.

Or you can trace a sketch made in advance on paper.

When the layout of the box is ready, we proceed directly to drawing the drawing. This is done using a ballpoint pen or a sharpened pencil. Please note that you will have to trace the patterns several times on both sides. This will make the design more decorative and convex.

You yourself were able to see that it is very easy to make products from thin sheet metal.

You may well be able to try your hand at this. You can make not only boxes in this way, but anything that comes to mind.

How to turn a hobby into a small business

Making such exclusive gifts can also be a profitable business. You can sell crafts through advertisements or recommendations from friends. If there is a salon in your city that accepts souvenirs, you can donate them there. It is quite profitable today to create metal products with your own hands. They can be put up for sale on many specialized websites. Such online sites are easy to find. The “Masters Fair” works well, but you can use other services.

How to sell your crafts online

If you decide to opt for online trading, then take into account that the operating principle of all stores is the same:

- You register as a craftsman who sells items.

- Fill out your profile.

- Exhibit your work.

- You come to an agreement with the customer.

- He pays for the goods.

- You deliver.

There you can display both finished items and take orders. It is very important to choose the right product category, come up with its description, and choose a high-quality image. Be sure to write a caption for the photo and indicate that you make metal products with your own hands. We accept exclusive items for sale that can easily be sent by courier or by mail to the customer. Items should not contain very thin or fragile items that could break during transportation. If such parts are available, you must provide high-quality packaging so that the product reaches the client in its original form. After all, every mistake can significantly affect your image. Try to complete all decorative metal products with high quality and on time. Good customer reviews play an important role in this line of work. This way you can turn your favorite activity into a source of income.

Finally

So, as you understand, it is quite easy to make metal products with your own hands. This type of activity would be an excellent hobby option. Also, your friends and family will be the happy owners of exclusive gifts. In addition, by offering samples for sale, you will create an image of a good craftsman and be able to make a profit.

Crafts from scrap metal

From what's lying under the welding table. Please do not judge too much for the clumsiness, but because... There is no grinder or milling machine, it was made using a grinder, electric welding, a file (when I was not too lazy))), and a cutter.

Moreover, it was done during lunch breaks, and when you are late...)))

I'll start with small things like cold stuff. From the bearing race. Hardening and tempering are done in a smart way, you can shave.))) I tempered it in an oven for calcining the electrodes.

Full size. Spring, bearing race. The pistol on the right is a working scarecrow gun with primers. At first I made it with construction cartridges, but it hurt my ears in the trash...))) The Kholodnyak (large) was forged and hardened in a forge.

Full size. Spring, bearing race. The pistol on the right is a working scarecrow gun with primers. At first I made it with construction cartridges, but it hurt my ears in the trash...))) The Kholodnyak (large) was forged and hardened in a forge.

Full size MG.

Full size MG.

Everything works until the drummer clicks. I did it for a week (if you count a couple of hours a day). Not working sights (in the sense of not moving). And the cupcake does not open (why, there are no cartridges anyway)))).

Source: The same thing - until the click. Magazine without spring. Not collapsible. I did not make a muffler or a cover for the barrel.

Source: The same thing - until the click. Magazine without spring. Not collapsible. I did not make a muffler or a cover for the barrel.

I experimented with wood.)))

I experimented with wood.)))

ya-superpuper.com

DIY crafts for the garden: step-by-step ideas and photos

For all lovers of tinkering, inventing and being creative, our today's selection of DIY crafts for the garden is intended. There is no single concept in them, some of them have practical significance, others are intended purely to lift the mood. On the other hand, isn’t this the most important thing we want to see in crafts for the garden?

DIY crafts for the garden: photos

Most of the DIY crafts for the garden, photos of which you will see below, are made from simple materials that are accessible to everyone. They will not require possession of complex tools, although construction skills may be useful to you, as well as artistic imagination. In addition to wood, plastic and metal, which we have traditionally used for many years, designers offer us new ideas for the garden. for which unusual materials are used. Who among us could have imagined that knitted items could become decorations for the site? And they did! We present to your attention a whole family of hedgehogs created using knitting needles and thick woolen threads.

Hedgehogs will look great both on the lawn, in the grass, and on the veranda or in the house. Such interior crafts will also be excellent souvenirs for friends. As you can see, they are all different sizes, all because they are based on cans and tins of different sizes. Even a child can make them if he has the most basic knitting skills in his arsenal. Pay attention to the choice of thread shade to imitate needles. If you cannot find melange yarn in shades of gray, black and white, then you can do it differently and simply knit in two threads, connecting black and white. In order to determine the size of the canvas, use a centimeter to measure the selected container: circumference and required height. Cast on the knitting needles the number of stitches that will correspond to the circumference. Use regular garter stitch, alternating knit and purl stitches. When the fabric is knitted, sew it like a sleeve and draw white threads through the narrow edge. They are knitted with four needles or special sock needles, on four sides. After knitting a little, put a jar inside the resulting stocking, which is intended for the base. After this, tighten the “rear” of the hedgehog with threads. Starting from the middle of the white knit, halve the number of stitches in each row to create an elongated muzzle.

At the very end of knitting, replace the white threads with black threads literally for a couple of rows to create a nose. All that remains is to sew on buttons as eyes, construct legs from threads, and the first hedgehog from a large family is ready.

A bird feeder is, of course, a noble craft, but cats may also want to occupy such a wonderful house. However, such crafts for a summer cottage made from logs are decorative in themselves, regardless of which residents occupy them. Moreover, at each site the fruit stock is renewed from time to time, so there remains a large number of logs that can be used for work. This design is very simple, but looks very impressive, especially if you place it on the territory of an alpine hill or in dense thickets.

Beer in cans and metal bottle caps do not have to be thrown into the trash. Start saving raw materials in the winter so that in the summer you can delight your children with funny metal crafts for your summer cottage in the form of owl faces.

To work, you will need a variety of metal parts and pieces (you can even see crafts made from a bicycle wheel below), but the principle of operation is the same - two more round parts are screwed onto the round base part with the help of screws - the eyes of an owl, and a tiny nose between them. The fastening is done using wire; it is inserted into the base material, three pieces on each side, to imitate claws and screwed to a branch, beam or other place where you want to place the craft.

DIY craft ideas for the garden

When looking for ideas for DIY garden crafts, you can go far and find products that are actually complex designs.

On the other hand, they are the ones that will cause the greatest delight among your guests, in contrast to the simplest crafts made from bottles for the garden. which are available at every site. You can try to make the following characters that will enliven your country landscape if you have minimal skills in creating sculpture. And, by the way, the basis of these garden sculptures are plastic bottles, but no one will guess about it except you.

To sculpt such a work, you will first need to create a frame from bottles. If you want to make figures as large as in the photo, then you will need to use not ordinary 1-2 liter bottles, but 5-6 liter eggplants. They are inserted into each other, each of them is first cut in half diagonally. Pieces of plastic pipes will serve as arms and legs; you can also bend them as you please. At the ends of the tubes we attach pieces of wire, between which we glue the fabric, we get excellent webbed feet. When the frame is completely ready, you can begin to cover the surface of the plastic with facade putty, dilute it to a dense consistency and coat the frame with an even layer. We cover the dried plaster with paint, and then glue the fabric on top of it with folds that will look like frog skin from a distance. And the final stage - we apply paint and PVA glue to the fabric, which will allow our figure to be in the open air, without fear of the sun, wind, or rain.

The following inhabitants of the decorative garden with their own hands are also dedicated to recycling materials harmful to nature. These chickens are made from colored plastic bags, which means they won’t be afraid of moisture either and will be able to please you for a long time. The only negative is that in the bright sun they can burn out and lose the brightness of their plumage. To create a polyethylene chicken coop, you will first need a frame made of thick wire. Take thick bags of bright colors, cut them into strips and string them on a needle, collecting them into a frill. This thread (or fishing line), on which the bags are located, is gradually tied around the frame. But while it doesn’t look too much like chicken, to do this, arm yourself with scissors and simply trim the layers of polyethylene, removing all excess. In order for the chicken to stand confidently on the ground, two wire legs are screwed to the frame and tied with black electrical tape. The final stages are purely decorative - make eyes, a beak with a beard and a comb for the chicken. For quiet purposes, you can use thick cardboard.

How to make DIY crafts for the garden

We continue to look for interesting ideas on how to make DIY crafts for the garden from materials that you have at hand. The following example can be recommended for those who have recently completed renovations, because we will recycle the remains of a corrugated pipe by making bright pumpkins out of it.

You can make such metal vegetables for your garden with your own hands in literally a matter of minutes. In the photo you see a hint on how this can be easily done: the pipe is simply pulled to the center and the edges are connected, for example, with an industrial stapler. After this, when the correct shape has already been acquired, you very quickly paint the metal using orange spray paint. We insert a piece of pipe and some building fibers inside. Now orange pumpkins will decorate your yard not only in the fall, but all year round, confusing your neighbors.

If you like to play bowling and you miss this hobby at your dacha, you can make a children's bowling alley from plastic bottles. But it’s boring to just knock down bottles filled with sand; it’s much more interesting when they are painted. These could be gnomes, as in the example, or the faces of characters from your favorite children's cartoons; in any case, knocking them down even with a simple soccer ball instead of a ball will be fun.

Beautiful DIY crafts for the garden

The following beautiful DIY garden crafts look different, but they are based on the same manufacturing principle. These are balls made of concrete and then covered with paint.

If in the first case this is an excellent decoration for a playground, then the second option, using metallic paint, makes such decor unearthly, cosmic.

Canisters of various detergents also have to be disposed of somewhere. We offer you two options for such artistic recycling. You can use a canister of even bright color to make a figurine of such a funny boar. You will need a minimum of additional materials - anchor bolts for the legs with hooves, an old brush to create real boar bristles and pieces of matching plastic for the ears. You can make one or a whole brood and place it for permanent residence in the sandbox.

And from a canister with inscriptions you can make a bird feeder. It must first be thoroughly rinsed and ventilated to remove any remaining chemicals. Cut out the middle so that there is space for pouring food, but there are still high enough sides. The surface of the plastic is smeared with PVA glue and hemp rope or twine is wound onto it in even rows.

Creative ideas for arrangement can be applied everywhere, even in the unusual design of a palisade. It immediately takes on an unusual look; it’s worth sharpening each peg and painting it with paint in different colors. This original set of colored pencils will not leave indifferent not only children, but also adults

Unusual DIY crafts for the garden

Unusual DIY crafts for the garden are limited only by your imagination, since if you have detailed information, any of us can create simple figurines. These could be crafts made from disks for the garden. painted stones, mosaics on the paths or elegant straw effigies.

The only thing you should always remember is that the decorative elements should still be beautiful so as not to look like just cut-off plastic bottles. If you are not confident in your artistic talents, then it is better to buy ready-made crafts in a store or order weaving, forging, and sculpting craftsmen who already have experience in creating garden beauties.

If you liked the article, express your “thank you” by clicking on the buttons below:

Imagine that you have become the owner of a suburban dacha in a beautiful place and with wonderful clean air!

But for now, your plot is just a gray, featureless piece of land, without buildings, country houses, fruit trees and flowers. How to register your summer cottage? How to make it alive, beautiful and attractive?

Some good tips in this article. For a person who has his own farm - a storehouse of wonderful ideas! I know firsthand: drinking water for chickens or other poultry has always been a problem. After all, it is not advisable for chickens to get wet, especially their legs. Often because of this they start to get sick. Therefore, a selection of ideas is a very useful hint.

My mother-in-law has a lot of laying hens, but I have never seen anything like this. I especially liked the ideas of drinking bowls for chickens; I would recommend such solutions to my mother-in-law. I think she will be only happy, and so will the chickens.

The system is very simple to operate, but the benefits are maximum, and it’s convenient for everyday use; you fill it with water and you don’t have to think about constantly adding it as the water flows. Convenient both outdoors and indoors. We still have pieces of pipes left after the repair; there will be a place to put them to good use.

Photos of forged products

If you love the strength of metal and the sophistication of its forms, then the selection of forged metal products will not leave you indifferent.

As you can see, the photo shows various household and interior items consisting entirely of forged metal, or including part of it.

Artistic forging fits perfectly into the interior, adding charm, notes of romanticism and antiquity to ordinary objects. As you can see, forged can be gratings, fences, furniture legs, headboards, bases and stands for lanterns and much more.

Forged products can be painted in any color, but black forged products are considered a classic option.

Forged products have not gone out of fashion for many years; they are a kind of classic style that emphasizes the exterior of any area. It is also noteworthy that forged products fit well into almost any room interior.

All photos on this page are taken from the site kuzniaoreh.ru and the products depicted on them were made by the “NUT” forge

DIY metal furniture - making metal furniture for home and garden

Several samples of metal furniture, which we want to bring to your attention, are easy to manufacture and practical. The absence of adhesive joints and the relatively low weight of metal furniture allow us to recommend these products as garden furniture and garden furniture.

Manufacturing of metal furniture

Special techniques are typical for making furniture with your own hands from metal., which you need to know. The starting material is usually duralumin or thin-walled steel tubes with a diameter of 16 to 22 mm. For metal furniture, the manufacturing process of which is described in this section, you can use disused duralumin folding beds, folding chairs, ski poles, etc.

The main operation in the manufacture of metal furniture is pipe bending. At home, this operation is easiest to perform in a special device consisting of two bars and a flat disk.

It is advisable to make the parts of the device from hardwood and securely fasten it on a solid base (workbench, table, etc.).

P.). The bars of the device are fastened so that there is a gap between them, allowing you to freely insert a pipe into it for bending. A prerequisite for the quality of this operation is to fill the pipes with sand or fill them with molten rosin. To do this, a wooden plug is hammered into the pipe blank at one end, then the tube is tightly filled with dry, fine-grained river sand. Now all that remains is to plug the tube on the other side and you can start bending.

When bending metal furniture parts of complex configuration, for example, a chair frame, it is necessary to use a plaz. The simplest bending plaza is a sheet of plywood or cardboard on which the contours of the future part are drawn. To reproduce the contour of a part on the plaza in full size, a coordinate grid is applied to it (similar to the grid shown in the figure on this page) and the configuration of the part from the drawing is transferred to the cells.

During the bending process, the part is periodically checked along the contour on the plaza. To connect pipe parts together, wooden adapter bushings are usually used, which allow the use of conventional fasteners - screws or studs. Plugs are placed in the supporting ends of the legs. Corks should be made from well-seasoned, dry hardwood. They can be turned on a wood lathe, and try to make the diameter of the plugs such that it ensures the tightest possible fit.

A few words about finishing metal furniture. Parts made of duralumin pipes are best finished by polishing to a mirror finish followed by coating with colorless varnish, but this is only possible with a power tool, an electric drill or motor, and a polishing wheel.

If you do not have such tools, then the metal parts of the furniture must be thoroughly sanded (especially steel) and painted with black or other colored varnish or paint for metal.

So, on the following pages of the site idea-master.ru we will tell you in more detail how to make metal furniture with your own hands: A round metal table, a metal chair, an armchair made of metal tubes, a kitchen table and a semi-soft metal bench.

All materials in the “DIY Furniture” section

How to make a bucket with your own hands from tin

How to make a bucket with your own hands from tin, galvanized iron or stainless steel with straight walls.

We cut out the product from the material

h– height (set the specified value)

d– diameter (set the specified value)

l– circumference (we find by calculation)

l = πd = 3.14 * 329 = 1033(mm)

h = 310(mm)

MANUFACTURING A CYLINDER

In the middle of the reamer we mark holes for attaching the ear

1.

On a rectangular sheet of thin-sheet galvanized steel GOST 14918-80, on a homemade manual sheet bender, or manually using a mallet and a beam, fold the edges of the sheet “heightwise” in opposite directions. Bend the sheet into a cylinder.

2.

We fasten the folded edges.

Press the resulting seam evenly with a mallet or mallet along the entire length of the cylinder.

3.

In order for the seam to remain inside the cylinder, it is necessary to carry out the following operation: turn the finished seam so that it is located near the edge of the beam; By hitting the seam with a mallet, we obtain the outer surface of the cylinder without a protruding seam.

FOLDING

The width of the fold depends on its purpose: obtaining a lock; rolling of wire.

4.

Set the cylinder relative to the block to its original position. Tap with a hammer and bend the fold.

5.

Tap with the pointed side of the hammer. We monitor the width of the fold - it should be the same.

6.

Align the fold by tapping with the blunt side of a hammer.

7.

We finally bend the bent fold at a right angle.

WIRE ROLLING

We insert a circle around the perimeter of the flange,

made of wire, the diameter of which must coincide with the outer diameter of the cylinder.

We round the circular edge and complete the seaming.

CONNECTION OF CYLINDER TO BOTTOM

8.

Fold the edges of the circle and insert it into the cylinder.

9.

With light blows of the pointed part of the hammer, we bend the fold inside the circle.

10.

Using strong blows from the blunt part of the hammer, we tap the seam on the beam, while turning the cylinder.

11.

We place the fold on the outer plane of the cylinder.

12.

If the work results in a convex bottom, it is necessary to level it.

13.

At the very edge of the bottom, we hit it with the blunt part of the hammer, along the entire perimeter of the circle. At the same time, the bottom will be leveled, the edges of the connection will receive a clearly defined contour.

ATTACHING THE INTERMEDIATE HOOP

The bottom of the bucket can be attached to the intermediate hoop, and the intermediate hoop can be attached to the cylinder.

14.

We attach the bottom of the bucket with a hoop.

15.

We connect the hoop with the cylinder (bucket body).

16.

We bend the fold at the hoop.

17.

We place the fold on the outer plane of the cylinder and thoroughly tap along the perimeter of the entire circumference.

MAKING THE EAR

We will cut out the ears from a similar material. Let's punch or drill through holes: two for rivets; one with a metal handle.

MANUFACTURING A HANDLE

We bend the handle from metal wire with a diameter of 5...6 (mm) GOST 18143-72.

How to make a bucket with your own hands from tin – as you can see, it’s not complicated. Having mastered a simple model. You can move on to a more complex model with sloping walls.

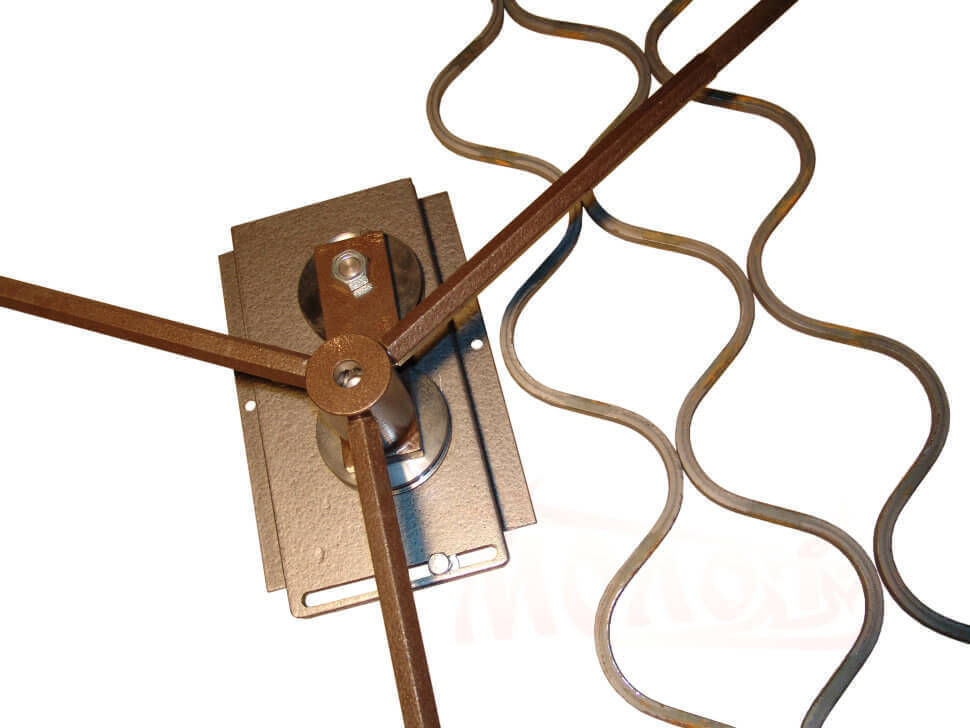

Admiring the beauty of an openwork metal fence or admiring the incredible twisted pattern on the railing of an iron staircase, few people think that they were made using the cold forging method. You can learn to embody beauty in metal without much effort. To do this, it is enough to have minimal skills in working with metal and have special machines for cold forging.

What is cold forging? What machines are needed for it? What can be made on these machines? You will find answers to these questions in our article.

It would be more correct to call cold forging - mechanical bending of a metal rod on specialized machines to give it the shape intended by the manufacturer. Bending rods in the machine can be done either manually using levers or using electric motors. In addition to metal rods, cold forging can be used to bend small-diameter pipes, narrow iron strips and fittings. Using the cold forging method the following are produced:

- Twisted fences.

- Decorations for residential buildings.

- Patterned gate.

- Railings for balconies and stairs.

- Metal garden benches.

- Decorations for gazebos and lanterns.

- A large number of grating options.

Elements made by cold forging

Elements made by cold forging Having mastered the cold forging method, you can easily start your own business producing metal products. At the same time, you will only need initial financial investments for the purchase of machines, and if you make the machines yourself, you can get by with minimal costs.

Below we will give you instructions on how to assemble cold forging machines yourself.

Machine "snail"

Making a snail machine is one example of independent design, and it makes no sense to give advice with an exact indication of the dimensions of all parts. You need to be guided by your idea of the operation of the machine, how and what will bend, how many turns of the spiral will be enough for high-quality work, what size the lever with the tabletop will be. If you understand the essence of the machine manufacturing process, then the assembly itself will not cause any particular difficulties.

Machine “snail”

Machine “snail” Manufacturing of main machine components

Frame.

The process of bending an iron rod exposes the machine to heavy loads, so when making the frame for the “snail”, only a metal corner, channel or thick-walled pipe is used. Do not make a frame from wooden beams; such a table cannot withstand prolonged loads and collapses.

Tabletop.

The tabletop for the “snail” is made of a metal plate cut in the shape of a circle, at least 4 mm thick. From the same slab, a second tabletop is cut out, repeating the shape of the first. The snail segments will be placed on the second tabletop and the products will be bent. During the cold forging process, the tabletop takes on the bulk of the load, so there is no need to save money and make it from a thinner sheet of iron.

Main shaft and lever.

The main shaft is placed centrally between the tabletops and is attached to the base using four right triangles. The shaft can be made from a thick-walled pipe of the required diameter.

The lever is attached to the shaft using a ring and rotates around it; in addition, a roller is installed on the lever for bending the rods on the upper tabletop.

Machine diagram

Machine diagram Marking and installation of attachments

Depending on whether you want to produce only the same type of samples or you need more artistic products, there are three options for the snail device.

Option #1.

This is the simplest of the three options; its essence is that the outline of a spiral is drawn on the tabletop.

Drawing of the snail segments

Drawing of the snail segments At its core, this is a drawing of future products that you will produce on the machine. After applying the diagram, it is enough to cut out several segments from thick strips of iron of different widths that follow the line of the drawing and weld them to the tabletop according to the markings. With such a static “snail” you can make simple bends.

Option #2.

The second option is the most popular among homemade machines; it involves making a collapsible snail from removable parts. Holes are drilled along the contours of the markings into which threads are cut. Next, templates for the stop segments are made from cardboard or plywood and metal overlays are made from them. Finally, holes are drilled in the pads, which should coincide with the mounting sockets on the tabletop. To secure the segments, bolts are mainly used, but you can also make cylindrical stops. This “snail” design will allow the production of spiral-shaped workpieces with different radii on one machine.

“Snail” made of metal strips

“Snail” made of metal strips Option #3.

In the third option, instead of collapsible stop segments, several removable modules are made with different volute options, which change as needed. The module is made of a piece of iron onto which segments repeating parts of the spiral are welded.

Snail modules

Snail modules Machine assembly.

- Install the frame in a place where you will have easy access to the machine from all sides.

- Concrete the legs of the frame in the floor or secure the frame in another accessible way.

- Weld the main table top to the frame.

- Install the main shaft by welding it to the tabletop and strengthening it with triangles.

- Place the rotating lever onto the shaft.

- Install the top tabletop by welding it to the main shaft.

- Place the snail segments on the tabletop.

After assembly, test bend the rod.

To learn more about assembling a snail cold forging machine, watch the video:

Torsion bar machine

This machine is designed for uniaxial longitudinal twisting of a workpiece from a transverse or square rod.

Torsion bar machine

Torsion bar machine A channel or I-beam is used for the base of the torsion bar machine. A thick iron strip is attached to it by welding, onto which a vice is installed to clamp the stationary part of the rod. The vice is secured with four bolts with a diameter of M16 or more. To increase the clamping strength of the bar, corrugated sheet steel plates are welded onto the vice. On the opposite side of the base, guide rollers are installed, to which a clamping unit for the movable part of the workpiece is attached. It is made of a steel bushing, in which it is necessary to provide holes for clamping bolts located at an angle of 120 degrees. The bolts must have a flat end and be made of high quality steel. Both clamping devices must be positioned coaxially; to do this, they must be checked using a level, a plumber's square and a caliper.

Types of machines

Types of machines Next, you need to make a handle for turning the moving part of the clamp. Its lever should hit as long as possible to reduce the applied force. It is better to make the handle itself with a rubber bushing to prevent the hand from slipping during operation.

After the machine is fully assembled, it is checked for the reliability of the moving elements and the accuracy of the deformation of the bar. After checking, the machine is attached to the support frame.

A simple model of a torsion bar machine

A simple model of a torsion bar machine How to make a torsion bar machine with your own hands, watch the video:

Machine "gnitik"

To qualitatively form a corner in a product produced by cold forging, you will need a machine called a “bend”. It consists of a steel plate with a movable stop on which there are two support shafts and a lever.

Machine “gnutik”

Machine “gnutik” The workpiece is placed between the wedge and the support shafts. After this, with the help of a lever, the wedge is shifted towards the shafts, which leads to bending of the workpiece.

Computer model of the machine

Computer model of the machine Making such a machine is quite simple, the main thing is to follow the given drawing and use tool steel, since during operation a large load is placed on part of the device.

You can also watch how to make a “gnitik” machine in the video:

Wave machine

It would be more correct to call this machine a controlled wave. The equipment of the machine consists of a pair of steel disks with a diameter of 140 mm, which are bolted to the worktop. The axis of rotation of the universal wrench is fixed to the drive disk.

Machine “wave”

Machine “wave” Wave control occurs as a result of changing the distance between the disks. When the bar is rolled around the drive disk with a knob, a pattern is formed, after which the bar is removed from the conductor and a pattern is formed on the other side.

You can watch the machine in action in the video:

Press machine

A press is needed to form the ends of the rods. This machine works on the principle of a flywheel; first, by rotating the bar with weights, the screw striker is pulled back until it stops. After this, a replacement stamp is inserted into the slot and the workpiece is placed. Next, quickly spin the bar in the opposite direction and leave it to rotate freely. Finally, the striker hits the stamp shank strongly, due to this, a force sufficient for stamping is developed.

Rolling press

Rolling press As for the manual rolling mill, you can make it yourself, but you still have to order special steel rolls, bearing bushings and shafts, and buy gears in the store. Only “crow’s foot” and “leaf” tips can be produced on such a machine.

Connecting and painting parts

Elements produced by cold forging are connected in two ways:

- Welding - the parts are welded to each other, and the scale is ground off with a grinder or other grinding machine.

- Clamps - this type of connection looks much more beautiful. For clamps, stamped strips of metal with a thickness of 1.5 mm or more are used.

Finished products are painted using blacksmith enamels or acrylic-based metal paints.

Connecting parts using welding

Connecting parts using welding Products produced by cold forging

We invite you to familiarize yourself with the options for products that you can make using the cold forging method:

- The fence element is completely made using the cold forging method. Clamps are used to connect the parts. The following machines were used for manufacturing: “snail”, torsion bar, “bend” and “flashlight”.

- Soda bench - made by cold forging and covered with wood. Welding and clamps are used to connect the elements. In production, machines were used - “snail”, torsion bar, press.

- Balcony railings - production method - cold forging. The railing elements are connected using welding and clamps. The machines used in production are “wave”, “snail”, press.

- Stair railings are produced using the cold artistic forging method. The parts are connected by welding. The machines used in production are torsion bar, flashlight, and snail.

- Visor - the frame of the visor is made using cold forging. The parts are connected by welding. In the manufacturing process, machines were used - “snail”, “wave”, press.

- The grill is a simple design made using the cold forging method. Clamps and welding are used to connect the parts. The barbecue elements were produced on machines - torsion bar, "snail".

- Double bed - cold forging method is used for the backrests. Connections are made by welding and clamps. In the manufacturing process, machines were used - “snail”, “wave” and press.

As can be seen from all of the above, the cold forging method does not require large financial costs and is quite easy to learn, so if you decide to start learning blacksmithing with this method, then you did the right thing.

You can make jewelry, figurines for the garden, an owl, a spinner, legs for an ironing board, and even a berry harvester from metal.

Metal crafts are the most durable. You don't need a welding machine to connect parts. This can be done using a soldering iron or superglue.

DIY metal owl

It's interesting to create something like this. You can make it from unnecessary parts. Here's what's right for you:

- bicycle chain;

- one M16 nut;

- two M8 nuts;

- two M10 nuts;

- 2 reinforced washers M6;

- 2 bicycle bearing balls;

- one small self-tapping screw;

- 5 or 6 cm of wire, the diameter of which is 3 mm.

When you make metal crafts like this, immediately place the parts face down so that you can use them correctly. This also applies to the owl's eyes, which you will do first. Attach a metal ball to these parts and connect them together by welding, soldering or using superglue.

And here's what the owl's eyes will look like from the other side.

The body of the bird will be an M16 nut, which is what you will attach to the eyes you just created.

Don’t forget that you need to connect the parts using any of the three above methods from behind, then the owl will look neat from the front. The beak will become a self-tapping screw. Attach it between the eyes, and glue or solder a metal wire bent in half without winding onto the top of the screw.

You can make the eyebrows at any angle to give the metal owl an angry, good-natured or thoughtful look. The wire bends well.

Take 2 washers and use pliers to fold each one in half. This will give you owl wings. They need to be attached to the side of a large washer, which is the body.

In order for the owl to stand firmly on its feet, or rather, on its paws, you need to make a pedestal for it. To do this, you can take a variety of metal objects.

Wrap such a circle with a chain if you want the owl podium to be so delicate. Place this wise bird on top of it by gluing, soldering or welding it.

And from unnecessary metal objects you can make several of these birds, then you will have a whole collection.

Metal crafts can be made from the most unexpected objects. For example, if you have replaced a faucet, do not rush to throw it away. You will get a wonderful long-lasting spinner. To do this, you only need a rotary water supply knob. Therefore, if you changed this part, use the old unnecessary one.

How to make a spinner from a metal tap?

Take the faucet handle and cut off the unnecessary part. The remaining workpiece must be well sanded with a file in the place where it was cut so that there are no nicks.

Take a bearing that fits the size of the hole in this faucet handle part. If, as in this case, it is a little smaller, then you need to first wrap it in paper or foil and trim off the excess.

But first, prepare the bearing, wash it in technical lubricant so that the finished product rotates well, without effort.

Place the bearing in place after wrapping it in paper. You will cut off the excess paper. Now apply glue to the junction of the hole in the faucet handle and the bearing, lubricating the paper with it.

Now put this part in place, in the hole in the faucet handle.

This is such a great metal spinner. Now you can rotate it, play and not be afraid that it will break.

When you have mastered such simple things, you can move on to more global ones.

How to make flowers from metal?

This material makes beautiful, long-lasting flowers. See how a rose is made from metal.

For this one you will need:

- thin sheet steel;

- hammer;

- steel rod, length 38 cm;

- pliers;

- tag for manual arc welding;

- acetylene torch;

- manual coffee grinder;

- hammer with a sharpened edge.

First, draw and cut out future flower elements on paper to make a template. The first layer of the plant includes a small bud, which is bordered by three petals. The diameter of this blank is 7 cm. The second row includes five petals with a diameter of 9.6 cm.

The third row includes five petals, the diameters of which are 12 cm. The 4th and 5th rows each include 6 petals with a diameter of 14.4 cm.

The last row is 5 identical petals with a diameter of 9.6 cm.

Attach the resulting templates to the sheet metal and outline them with chalk or a dry bar of soap.

Place templates close together to save material.

Now cut out these tiers of rose. Do not throw away the cuttings, as you will then use them to make leaves. Now take the petal blanks, drill a hole in the middle of each, the diameter of which is 0.6 cm. Using these holes, you will then string those blanks onto the stem. If scale remains after cutting, it must be removed. You do this by passing the flower elements through sections of a hand grinder.

To make a metal rose, start assembling it. To do this, fold the first two rows; these petals do not need to be given a special shape. Now string the first row of petals onto the rod and move it to the edge. Heat these blanks until the metal turns red. Now you will bend them using a hammer and pliers. Shape the bud so that it becomes dense.

Also, a steel workpiece can be processed with a torch clamped in a vice. Now attach the second row of petals to the stem. They will also form a dense central bud.

Next, such flowers are made from metal as follows. You also need to string the remaining petals, but their ends need to be textured. Let the edges be wavy so that they resemble the petals of a real rose.

The row with the sepals needs to be folded downwards. Make a weld along the stem to strengthen the metal flower.

From the material you have left over from cutting out the petals, cut into leaves. They need to be shaped and then welded to the stem. To make spikes on it, turn off the gas on the welding machine for a second. Then the metal will begin to come out. Lean it against the stem to create thorns.

This way you can make metal flowers in large quantities, creating such a picturesque bouquet.

If you have a pile of unwanted metal spoons, instead of throwing them away, you can also make long-lasting flowers. Check out the following ideas. They will tell you not only how to make picturesque bouquets, but also various figurines, watches and other items.

What can be made from metal spoons?

This flower for the garden is made from metal spoons and a small bowl. We cut off the straight parts of the spoons with pliers, and the curved parts will just need to be glued with superglue around the bowl or attached using a welding machine. If you also have unnecessary forks in your household, they will help you create the following metal crafts.

To do this, you also need to cut the straight parts of spoons and forks, then fasten them together. Around the core of forks you will place spoons in two tiers, which will allow you to make lily petals. But don't throw away the straight parts of spoons and forks, they will help you create your next metal crafts.

Take these remaining pieces and bend them using pliers. Now spread evenly on the work surface so that the parts with the ornament are on the outside. Glue or weld these elements to a round washer or metal object of this shape. Attach an iron or aluminum stem; the same handles from spoons and forks can become leaves. And from the working part of these tableware you will make petals for the next flower - it is located in the photo on the right. As you can see, the outer petals are spoons and the inner petals are forks. Attach them to the core of a round shape and fix it on the stem, which is covered with leaves. The next metal flower will be created using two rows of spoons. You will place some working parts on the back side, and others on the front side.

If you have a lot of spoons of different sizes, then make a multi-tiered flower out of them. You will attach small coffee spoons in the middle, followed by a row of teaspoons, then dessert and tablespoons. You can paint the core to make it look so elegant.

And if you have old spatulas, you can weld them together to create a flower. You can use metal spoons instead.

Other metal crafts are also interesting. For the next one, you will need to use a template to write numbers or glue them. Attach a clock mechanism to the back of the metal circle, and fix the arrows on the front side. The spoon will become a minute, and what about an hour? fork. Also, these cutlery must be glued to the back of this circle to create such an original clock.

If you have old, unwanted knives, turn them into dragonflies.

4 spoons will turn into butterfly wings, and the handle will turn into its body. Such garden crafts will decorate your hacienda and you won’t have to spend money on them.

And in the house you will place a photograph, a regular fork will become a holder for it. Then you will need to bend the two side teeth forward and the two central ones back using pliers.

But this is not the only decoration that can be made from metal. Bend the working parts of the forks, pulling them towards the fork handles. At the fold, a loop is formed where you will thread the chain.

And bend the tines of the forks so that they become wavy, and some turn into curls.

If you completely remove the working parts of forks or spoons and drill a hole in the handles, you will get original earrings.

If you like black and white, take a dark colored base and glue white painted cutlery onto it. Use a light frame. Foam ceiling plinths are suitable for it.

If you want to entertain guests at the highest level, make napkin rings from spoons. They need to be bent, and an artificial stone or amber should be placed in each spoon. Secure this decoration with wire, giving it the desired shape.

Speaking about what can be made from metal, it should be noted that even an old ladle from this material can be turned into a candlestick. Attach it and place a candle in the scoop.

If you glue cutlery to the back of a round mirror, it will look like the sun. It's nice to look like this accessory.

Even furniture handles can be made from metal. Cutlery is also used as them.

Such an original solution will certainly be appreciated by guests and family.

If you need to put small things somewhere, you can use ladles and spoons for this. They need to be slightly bent and threads, paper clips, and clothespins placed in the working parts.

If you polish the spoons, you can make sparkling fish out of them. To do this, saw off part of the handle from each, leaving a small tail, which you will cut into 2 parts with metal scissors. Drill a hole in each piece that will become the eye. And through the hole at the top you will stretch a thread or fishing line and hang the fish on a fork, giving the teeth an interesting shape. Then the fork will look like an octopus.

You can make this kind of garden decor out of metal.

If you need to call your family for dinner, you move these forks, they will make a sound like bells. Also, hanging cutlery can blow from the wind, and you can listen to the music of the wind.

How to make a berry harvester yourself?

You can also make it from metal with your own hands.

To make one, take:

- galvanized steel;

- tin and flux for soldering;

- marker;

- metal scissors;

- steel wire;

- hammer;

- steel wire with a cross-section of 2 mm or bicycle spokes;

- aluminum tube taken from a ski pole.

Cut a couple of strips measuring 15 by 3 cm from galvanized steel and bend each in half lengthwise. On the one hand, at the end you need to cut 2 cm from one and 2 cm from the second workpiece.

On the folds of stripes 1 and 2, make notches at a distance of 5 mm from each other using an emery wheel.

You need to drill a hole at one and the other end of the bent workpieces, then make a marking to drill a hole at the ends of the wide strips.

Now fold these four pieces to form a quadrangle and secure their ends.

Insert the knitting needles into the created notches. They must first be treated with soldering flux, then soldered to one and the other strip.

To make a holder for a metal craft, cut 2 strips measuring 15 by 1 cm from a sheet of steel. But if you don’t want to do this, then just take two flat skewers.

Cut a piece 18 cm long from the aluminum pipe and flatten the ends of the workpiece, then make a hole in these places.

Now take two narrow strips or two skewers if you used them and drill holes in the center and at the ends. Bend each piece on both sides as shown in the photo.

Rivet these curved pieces to the ends of the tube to make the next holder.

Using a hammer and chisel, you need to level the teeth, pointing them in one direction, and drill holes in the four corners of the walls. Lift the side walls by bending them inwards and attach the holder to the holes created.

Lift the knitting needles up and attach the bag, securing it with wire and rope. This is where you will put the berries. Even a trouser leg from unwanted jeans can be used as such a container. And its length can be adjusted by pinning it with a pin. Now you can collect wild berries using a do-it-yourself harvester.

The following product will also come in handy on the farm. After all, you can’t do without ironing clothes. And it’s quite possible to make a device for this with your own hands.

How to make a metal ironing board with your own hands

You can make it exactly the size that suits you. Perhaps ordinary ironing boards seem too narrow to you, and in order to iron large bed linen faster, you will make a wider one. Plus, you can save a lot of money.

In this case, the ironing surface is made of waterproof chipboard, but you can use plywood.

The standard size of an ironing board is 122 by 30 cm. If you need a narrower device so that it does not take up much space, then you will reduce these dimensions, and if you need a wider one, then increase it.

Sand the ends of the chipboard or plywood.

Now you will need to cover this blank with fabric. There is a coarser thick fabric going down, and a thinner fabric on top. Cut these materials with a 5 cm margin so that you can then tuck them onto the wooden base.

Attach using a stapler. This way you fixed a denser fabric. And on a thin one, you will need to make a drawstring on all sides, hemming it, so that you can then insert an elastic band or thread here. Then you will have a removable cover that you can wash if necessary.

But you may ask, where are the metal crafts? After all, the topic is just that. But it is from this material that the legs for the ironing board will be made. They are made using metal tubes with crossbars attached to them. Make holes in the center of the long tubes to then connect them with bolts.

Use rivets to attach the metal legs to the wood base. To do this, cut 4 strips of tin and give them the desired shape.

And the other two legs will be attached using a clamp, then it will be possible to give the board the desired height.

These are the metal crafts you can make with your own hands. You can make many more things from this material, for example, a fly, a spider, a web. Watch the process of creating these items.

Check out some ideas on what you can make from scrap metal.

Every owner spends a lot of time thinking about how to decorate their home. Today there is a huge choice of materials - wood or plastic, but in the first place is metal - one of the durable, strong, resistant materials in the world, serving as an example and standard of metaphors.

History of origin

Metal products became most popular in Europe in the 11th century. Everywhere, facades of buildings, fences, and decorative statues began to be decorated with unusual forging, and the profession of a blacksmith became an honorable and famous figure in the early Middle Ages.

What kind of craft can be made from metal?

Having thought carefully, the owner decides to present a piece of the unusual to his home, but the question immediately arises: should he buy it or make it himself? Of course, do it yourself, because doing something with your own hands is much more pleasant and more profitable from a price point of view.

Today, forged ornaments for grilles, doors or fences are in fashion; forged animals, a mysterious owl, or a Russian bear also look great in the garden. Ladies prefer forged bouquets, and a rose created with their own hands will surprise anyone.

What do you need to make metal crafts?

There are not as many tools as it seems, all you need is the following list:

- Photo of a craft you like;

- Paper;

- Welding machine;

- Chisel and hammer;

- Grinder for cutting metal;

- Special rust solvent;

- Pencil and scissors, when using a stencil;

- Several washers or bolts for decorative elements;

- Steel rods, from a few centimeters to a meter.

- The basis of creation is sheet iron.

Step-by-step DIY crafts

An original idea for a metal craft would be an owl. First, for aesthetics you will need a template or stencil. It can be made from a sheet of paper with drawings printed on it.

After cutting out the owl drawing, the stencil should be applied to a sheet of steel and the drawing should be transferred; it should be done in the most realistic way.

The next step is to trim the metal with a grinder and drill holes for mounting and inserting the owl's eyes. After creating the body, you should move on to the details: the legs are made from a rod, and the irregularities are smoothed out with a grinder. At the end, our beauty is treated with a chemical rust remover and painted.

Master class on making roses

And materials. List of basic tools:

- Welder.

- Hammer and pliers.

- Sheet steel

- Bulgarian.

- Special paint for metal.

- Grindstone.

- Steel wire with a diameter of 6 mm.

- Metal scissors.

Attention. Do not forget about safety precautions when working with these tools! Be sure to wear gloves and a welding mask when working.

We take metal cutting scissors and cut out thirty rose petals (thirty petals will make the bud seem more magnificent). You need to move in cutting from small to large, that is, from 15 mm to 80 mm. Your rose should not be prickly. Therefore, a sharpening stone will help smooth out all the unevenness of the petals.

After forming a complete flower, we weld the spikes and clean off the excess with a grinder, clean the seams and cover with a layer of protective paint - the craft is ready.

Metal products with steel wire

The British National Academy of Sciences declared in 1856: “Everything that can be invented has long since been invented,” but time has shown a different outcome. So it is now. Every year new ways of decorating are invented.

For example, in recent years it has been fashionable to make a figure from wire or rod. Combinations and special weaves create an impression of indescribable beauty.

Master class - butterfly made of twig

In terms of its complexity, a steel butterfly is not difficult and will not take much time. Typically, the work technique consists of twisting the wire (the manufacturing process depends on the correct material: the material should not be too thick so that it can bend, but should not be too thin so as not to bend) into several layers.

A body is created using spiral turns, after which wings made from two ovals are attached.

Some interesting facts

Metal is the most ancient mineral of interest to humans. He mined it, forged it, and then a new fence or another forged deer lit up the smile of passers-by.

During the rapid introduction of Hollywood films and the development of artificial intelligence, the topic of androids and the like became relevant. Although the world is far from the rise of the machines, it is always possible to forge a transformer, say, for an exhibition.

Vitaly Yashkovich from Krasnoyarsk became famous throughout the city for his miracle robots. His collection includes such titans of world cinema as: Megatron, Terminator T-200 and T-800, Star Wars androids, as well as droids from cartoons. The owner himself claims that he will not sell his robots to anyone, they say, he created for the soul

You too create, because the world is unidentified and multifaceted. Give him something new and unusual.

Photos of metal crafts